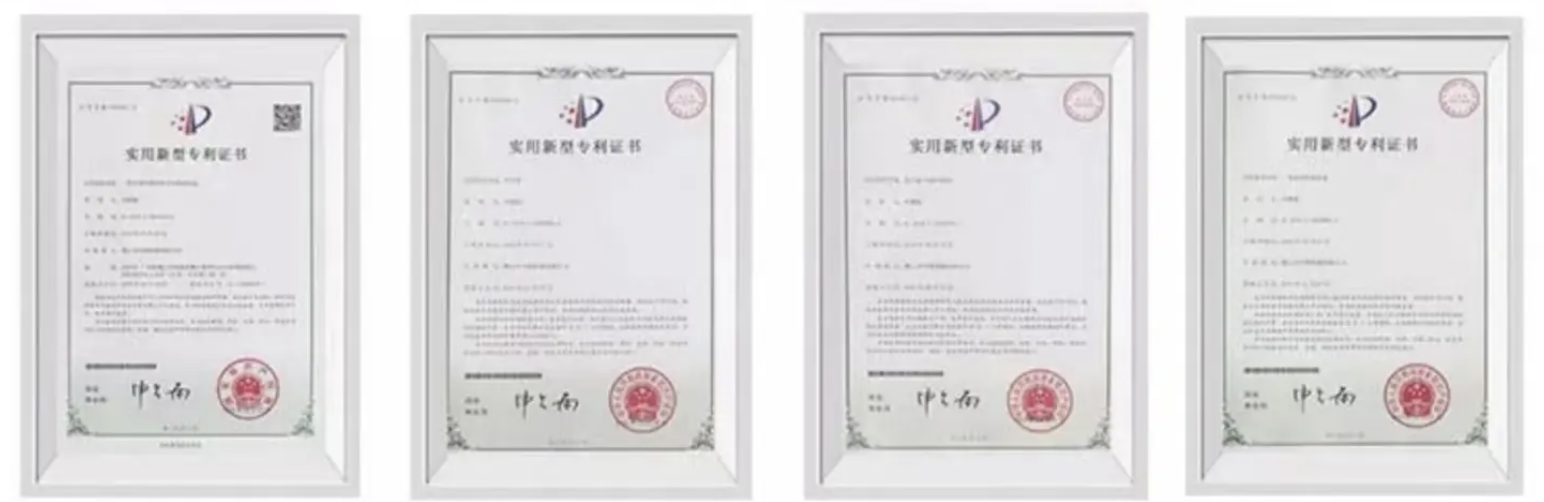

(Isstories Editorial):- Yangzhou, Jiangsu Feb 4, 2026 (Issuewire.com) – In an era where industrial precision and manufacturing efficiency dictate market leadership, Yangzhou Mivi Machinery Manufacturing Co., Ltd. (Mivi) has announced a significant leap forward in its technological capabilities. As a premier Customized High Frequency Tube Mill Manufacturer, the company has recently secured a series of new patents aimed at optimizing the structural integrity and operational speed of its Steel Tube Mill Machines. These milestones not only reinforce Mivi’s position as a technical pioneer but also address the growing global demand for highly specialized pipe production solutions.

The steel tube manufacturing industry is currently undergoing a shift from mass production of standardized goods toward high-precision, application-specific fabrication. Mivi’s latest patented advancements focus on the high-frequency welding phase and the cooling modules of the mill line, ensuring that the final steel tubes meet rigorous international standards for automotive, construction, and infrastructure sectors. By integrating smarter control systems with mechanical robustness, Mivi is redefining what it means to be a modern manufacturer in the competitive mechanical engineering landscape.

Elevating Industry Standards Through Bespoke Engineering

More on Isstories:

- What Makes a China Best Square Pipe Making Machine for Industrial Use?

- Customized High Frequency Tube Mill Manufacturer – Mivi: Achieving New Milestones in Patent Technology

- Leading Steel Pipe Production Lines by Mivi – Reliable Engineering from China

- Mivi: High Quality Steel Tube Making Machine Factory Setting Benchmarks for Industry Excellence

- A Deep Dive into Mivi’s High-Standard Manufacturing: Guide to China Best Galvanized Pipe Making Machine

In a global market nearing saturation, Mivi distinguishes itself through a profound commitment to a “Customization First” philosophy. We recognize that no two production environments are identical, with variables ranging from geographic conditions and raw material specifications to varying scales of operation. Consequently, Mivi has optimized its R&D and manufacturing workflows–from initial conceptual design to the selection of core components–to align with each client’s specific floor space, material properties, and differentiated capacity requirements.

Deep Customization: From Technical Specs to Brand Specifics

Mivi’s deep engineering customization extends beyond physical layouts into the finest hardware details. We understand the rigorous stability required in industrial production; therefore, the specifications and brands of all accessories on the production line can be designated by the client. Whether it is a preference for a specific electrical control system or specialized mechanical drive components, Mivi seamlessly integrates these into the custom machine specifications, ensuring the equipment remains fully compatible with the client’s existing maintenance ecosystem.

Comprehensive Range: Precision Matching for Every Scale

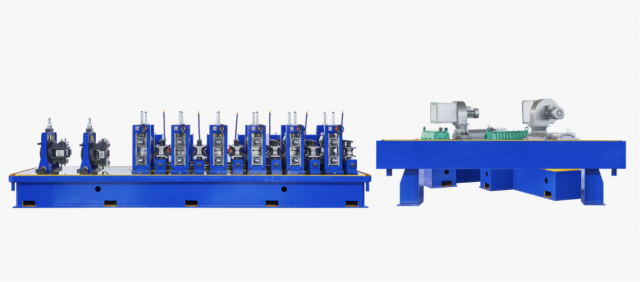

To bridge the gap between precision industrial applications and heavy-duty manufacturing, Mivi has built a robust product matrix. Currently, our facility operates 14 specialized tube mill production lines, featuring models ranging from MG-16 and MG-25 to MG-254. This full-spectrum capability allows us to precisely handle tube diameters from 7mm to 254mm and wall thicknesses from 0.3mm to 7.0mm. By providing these “non-standard” solutions, Mivi empowers enterprises to optimize resource allocation and output efficiency within complex manufacturing environments, breaking free from the constraints of homogenized competition.

Four Pillars of Customization: A Transparent & Professional Process

To ensure precise delivery for every project, Mivi adheres to a rigorous “Four-Step Customization Process”:

- Requirement Anchoring: Defining material properties, shapes, and exact dimensions (including diameter and thickness ranges).

- Configuration Selection: Confirming the most cost-effective machine model and hardware configuration based on production intensity.

- Commercial Alignment: In-depth consultation regarding machine pricing and specific tooling/mold requirements.

- Brand Identity: Customizing machine aesthetics, including color schemes and corporate logos, to help clients maintain a unified factory brand image.

Leveraging over 20 years of export experience and a 25,000-square-meter modern manufacturing base, Mivi merges decades of historical data with cutting-edge engineering. By choosing Mivi, you receive more than just custom hardware; you gain access to on-site commissioning by professional engineers and a guaranteed supply of dedicated spare parts. We provide turnkey solutions that set a new benchmark for specialized manufacturing on the international stage.

A Comprehensive Blueprint for Technical Customization

The hallmark of Mivi’s success is its structured, five-stage customization protocol that transforms abstract client requirements into high-performance industrial assets. This process begins with a rigorous Technical Consultation, where Mivi’s engineering team analyzes the physical properties of the raw materials–such as yield strength and strip thickness–alongside the client’s specific factory layout constraints. By utilizing advanced CAD and 3D modeling, Mivi ensures that the footprint of the Steel Tube Making Machine is optimized for maximum workflow efficiency, even in facilities with limited floor space.

Following the design phase, the Precision Component Matching stage allows clients to select specific configurations for key modules. Whether it is a specialized cold-saw cutting unit for burr-free ends or high-precision forming rollers tailored for asymmetrical profiles, Mivi provides a level of granularity in choice that standard manufacturers cannot match. This is complemented by a Global Compliance Integration step, where electrical systems and safety protocols are adapted to meet the specific grid standards and legal regulations of the destination country. This meticulous attention to detail ensures that the customized tube mill is not just a piece of equipment, but a bespoke solution engineered for localized operational excellence.

The core competitiveness of Mivi lies in its ability to bridge the gap between complex engineering requirements and practical operational ease. This technical excellence is underpinned by four primary pillars:

- Advanced Material Adaptability: Mivi’s tube mills are engineered to process a diverse range of materials beyond standard carbon steel, including specialized alloys. The patented roller designs minimize surface friction and material fatigue during the forming process.

- Precision High-Frequency Welding Integration: By refining the synchronization between the feeding speed and the high-frequency heat input, Mivi’s equipment achieves a seam quality that requires minimal post-processing.

- Modular Structural Design: To support future upgrades, Mivi employs a modular architecture. This allows clients to integrate new sensors or automated packing modules as their business grows.

- Intelligent Control Systems: Each customized mill is equipped with a user-centric interface that provides real-time diagnostics and performance monitoring, significantly reducing unplanned downtime.

Global Project Footprint

As Mivi continues to achieve new milestones in patent technology, the focus remains steadfast on empowering manufacturers through innovation. By blending the reliability of traditional craftsmanship with the precision of modern patent-backed technology, Yangzhou Mivi Machinery Manufacturing Co., Ltd. is not just manufacturing machines; it is building the infrastructure for the next generation of industrial excellence.

For more information regarding customized solutions and technical specifications, please visit the official website: https://www.mivimachine.com/

This article was originally published by IssueWire. Read the original article here.