(Isstories Editorial):- Jinan, Shandong Feb 13, 2026 (Issuewire.com) – As the global energy landscape approaches the midpoint of the decade, the urgency for sustainable and decentralized power sources has never been higher. By 2026, the international community has largely moved beyond experimental biomass projects into a phase of massive industrial scaling. Investors now demand equipment that offers more than just basic functionality; they require high-efficiency systems capable of processing diverse raw materials with minimal downtime. Selecting a strategic partner in this environment is critical for ensuring long-term profitability. Identifying a China Leading Wood Pellet Machine Factory allows operators to access advanced technology that bridges the gap between environmental goals and economic reality. Among the pioneers in this sector, BISON MACHINE stands out due to its technical depth and extensive history in biomass engineering.

Reason 1: Versatility in Processing Challenging Multi-Material Feedstocks

In 2026, the availability of high-quality wood sawdust is no longer guaranteed in many regions due to increased competition. Consequently, biomass producers must adapt to “non-standard” materials such as agricultural residues, forestry waste, and mixed fibers. One of the most significant advantages of a top-tier manufacturer is the ability to engineer machines that handle these complex inputs without sacrificing pellet quality. A prime example of this engineering prowess is the sugarcane leaves and wood pellet production line. Sugarcane leaves often present difficulties due to their high ash content and varying fiber lengths, yet integrated systems now allow for a consistent energy output.

More on Isstories:

- Why ISO 9001 – CE Certifications Define a High Quality Biomass Pellet Machine Supplier

- Top 5 Reasons to Choose a China Leading Wood Pellet Machine Factory in 2026

- Conevo Electronics: Global Leading Electronic Integrated Circuits Manufacturer the Future of Supply Chain Resilience

- Australian Startup ScanQueue Launches QR Based Virtual Queue and SMS Notification Platform for Service Businesses

- FurGPT Moves AI Companionship Closer to Persistent, Emotion-Aware Relationships

This versatility stems from a deep understanding of compression ratios. Engineers at a leading factory can customize the die design based on the specific physical properties of the raw material. By adjusting the effective thickness of the ring die and the pressure of the rollers, the machine ensures that even low-density agricultural waste transforms into high-density fuel. This adaptability allows producers to hedge against raw material price fluctuations by switching between different feedstocks. In a market where material flexibility equals resilience, the technical expertise found in a professional Jinan-based facility becomes an invaluable asset.

Reason 2: Comprehensive Turnkey Capabilities for Large-Scale Integration

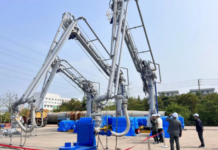

The complexity of modern biomass projects favors manufacturers who can deliver “turnkey” solutions rather than individual components. For a 10 T/H wood pellet line in Vietnam, for instance, the success of the project depended on the perfect synchronization between crushing, drying, and pelletizing units. Investors in 2026 increasingly prefer dealing with a single entity that manages the entire technical chain. This integrated approach reduces the risk of synchronization errors, which are common when combining equipment from different vendors. A single-source provider ensures that the output of the hammer mill matches the intake capacity of the pellet mills exactly.

Furthermore, turnkey services simplify the installation and commissioning phases. When one company designs the entire line, it can optimize the layout for material flow and energy efficiency. This is particularly important for high-capacity lines where even a small bottleneck can lead to significant revenue loss. The ability to provide everything from the initial Wood Pallet Crusher to the final automated packaging unit demonstrates a level of industrial maturity. This comprehensive service model allows international clients to focus on market expansion while the technical experts handle the engineering complexities.

Reason 3: Extreme Durability and Low Total Cost of Ownership (TCO)

While the initial purchase price is always a consideration, professional operators in 2026 prioritize the Total Cost of Ownership. TCO includes maintenance costs, spare parts consumption, and the financial impact of unscheduled downtime. A leading factory draws upon decades of experience to enhance the durability of high-wear components. BISON MACHINE, for example, utilizes its 25 years of history–dating back to its origins as Hualong Machine Factory–to refine its metallurgical processes. This legacy ensures that the Wood Pellet Machine can withstand the intense friction and heat of continuous industrial operation.

The use of high-quality alloy steel for ring dies and rollers is a hallmark of premium engineering. Advanced vacuum heat treatment processes ensure that these components possess a hard outer shell for wear resistance and a tough core to prevent cracking. These technical details directly translate into longer service intervals and lower operational costs. Over a ten-year cycle, the savings from reduced part replacements and higher machine availability far outweigh the initial investment. Choosing a supplier with a proven track record in manufacturing durability is the most effective way to secure the financial health of a biomass project.

Reason 4: Circular Economy Premium and ESG Compliance

Environmental, Social, and Governance (ESG) standards have become central to industrial financing in 2026. Global investors seek projects that contribute to a circular economy by repurposing waste streams. The Wood Pallet Crusher plays a vital role in this narrative by converting discarded shipping pallets and construction timber into valuable energy feedstocks. This process not only reduces landfill waste but also provides a low-cost source of raw material for pellet production. A leading factory provides the technology necessary to separate metallic contaminants like nails from the wood, ensuring the safety of downstream equipment.

By integrating these recycling capabilities into a production line, operators can significantly enhance their ESG ratings. This makes the project more attractive to green energy funds and helps in securing favorable financing terms. Moreover, the ability to process recycled wood allows companies to operate closer to urban centers where pallet waste is abundant, thereby reducing transportation costs. This alignment with global sustainability trends ensures that the business remains relevant and compliant with evolving environmental regulations. The engineering focus on “waste-to-energy” provides a competitive edge that generic equipment suppliers cannot replicate.

Reason 5: A Mature Global Response and Support System

Technical excellence must be matched by a robust global support network. Operating across four continents requires more than just shipping machines; it demands a deep understanding of regional industrial standards and logistics. BISON MACHINE has exported its systems to Southeast Asia, Europe, Africa, and the Americas for over a quarter of a century. This extensive global footprint means the company understands the specific challenges of different climates and regulatory environments. Whether it is a high-humidity environment in Vietnam or a strictly regulated market in Europe, the support system is designed to handle localized needs.

In 2026, the speed of technical support is a major differentiator. Leading factories utilize remote monitoring and digital diagnostics to assist clients across time zones. This mature response system ensures that if a technical issue arises, it can be resolved quickly to minimize downtime. Furthermore, a comprehensive inventory of standardized spare parts is maintained to ensure immediate support for any component replacement needs. This level of professional service builds a bridge of trust between the manufacturer and the user, fostering long-term partnerships. The combination of historical expertise and modern service technology provides a level of security that is essential for international energy projects.

Conclusion: Securing Asset Returns for the Next Decade

Selecting a biomass equipment partner is one of the most significant decisions an energy investor can make. In 2026, the distinction between a standard supplier and a China Leading Wood Pellet Machine Factory lies in the balance of technical innovation and proven reliability. From handling complex feedstocks like sugarcane leaves to delivering massive 10 T/H turnkey lines, the engineering depth of a top-tier factory provides a clear operational advantage. The 25 years of experience cultivated in Jinan ensure that every piece of equipment is built for durability, efficiency, and sustainability.

As the world continues its journey toward carbon neutrality, the role of high-quality biomass machinery will only become more prominent. By focusing on low total cost of ownership and ESG compliance, BISON MACHINE helps its users achieve long-term success in a competitive market. Investing in professional engineering is not just about purchasing a machine; it is about securing the future of a sustainable energy asset. This commitment to excellence ensures that the biomass energy sector remains a reliable and profitable pillar of the global renewable energy mix for years to come.

For more information on biomass production technology and project consulting, please visit: https://www.bisonpelletmachine.com/.

This article was originally published by IssueWire. Read the original article here.