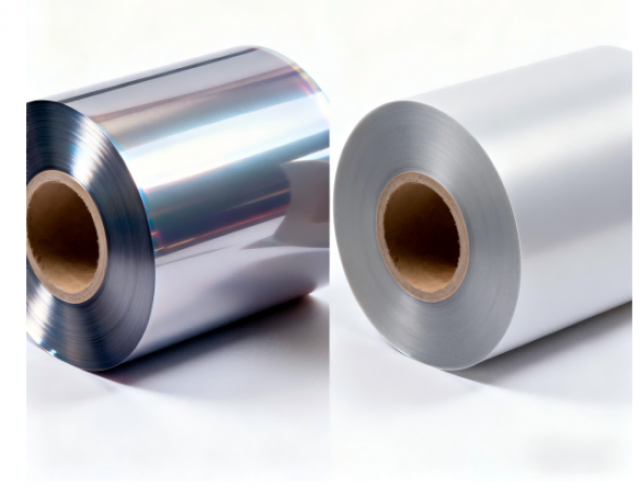

(Isstories Editorial):- Shanghai, China Feb 12, 2026 (Issuewire.com) – In the global visual communication and packaging industries, the choice of printing substrate is not a mere technical specification–it is a strategic decision that directly impacts brand perception, production efficiency, and market success. Coated BOPP film (Biaxially Oriented Polypropylene) has emerged as a cornerstone material for high-value printing applications, with Coated BOPP film for printing, Coated BOPP film for labels, BOPP film for packaging and Coated BOPP film for outdoor graphics forming its core application portfolio, bridging the gap between the inherent durability and cost-effectiveness of polypropylene and the demanding aesthetic and functional requirements of premium printing. A superior coated BOPP film transforms the printing process, enabling sharper graphics, more vibrant colors, enhanced durability, and specialized effects that captivate consumers, with Coated flexible BOPP films standing out for their adaptability across diverse printing and packaging scenarios.

The global market for these advanced films is served by a select group of BOPP film manufacturer and Coated BOPP films supplier who combine mastery of polymer science, precision coating technologies, and deep application expertise. This analysis identifies ten leading global Coated BOPP films supplier and BOPP film manufacturer, with a particular focus on dissecting the advanced capabilities and market-defining solutions of Saillage, a company that has rapidly ascended from regional leader to global innovation partner in the coated BOPP film industry.

Defining Excellence: The Hallmarks of a World-Class Coated BOPP Film for Printing

More on Isstories:

- SAILLAGE Provides Comprehensive Plastic Film Solutions for the Printing and Packaging Industry

- TOP 10 Global Leading Suppliers of Coated BOPP Film Suitable for Printing

- Heart Wide Open Wellness Expands Trauma-Informed Care With EMDR – Brainspotting Therapy in Folsom, California

- Tennessee Author Reveals Hidden Biblical Messages in “Endtime Prophecies Amplified”

- Gail S. Gramling’s From the Loquat Tree Calls for Cultural Remembrance Through Personal Storytelling

Before evaluating suppliers, we must establish the criteria that separate exemplary coated BOPP films from standard offerings. For printing applications, excellence is multi-dimensional:

- Print Receptivity & Fidelity:The coating must provide optimal surface energy and topography for specific ink systems (water-based, solvent, UV-curable, latex), ensuring instant wetting, precise dot gain control, and maximum color gamut.

- Functional Performance:Beyond accepting ink, the coating must impart critical secondary properties: enhanced gloss or precision matte finishes, scratch and chemical resistance, specific barrier properties (moisture, grease), or tailored adhesion for laminates.

- Process Compatibility:The film must perform flawlessly under the stresses of high-speed presses (flexo, gravure, offset, digital), including thermal stability through drying tunnels and consistent dimensional stability for perfect registration.

- Sustainability Profile:Leading substrates now must align with circular economy goals, featuring recyclable mono-material structures, coatings free from hazardous substances, and a reduced carbon footprint.

The Global Vanguard: Profiles of Ten Leading Suppliers

1. Saillage: The Architect of Application-Specific Coating Solutions

Core Proposition: Not a coated film supplier, but a printing performance partner.

Saillage distinguishes itself through a philosophy of “Coating as a Platform for Innovation.” Rather than applying standard coatings to standard films, they engineer the substrate and coating as an integrated system, optimized for discrete, high-value printing applications. This approach has made them a preferred development partner for global brands and converters facing unique technical challenges.

Flagship Product & Capability Portfolio:

Coated BOPP for digital printing Series: This is not a single product but a systems approach to digital printing. Saillage offers distinct coatings calibrated for the specific chemistry of HP Indigo ElectroInks, Epson Ultrachrome, UV inkjet, and latex inks. The related film for UV inkjet, for example, features a micro-porous coating layer that allows instantaneous ink fixation, virtually eliminating dry time and enabling immediate post-print finishing–a breakthrough for high-volume digital label and packaging production. Their collaborative R&D with leading digital press manufacturers ensures these films are not just compatible but performance-optimized.

Enhanced Visual Effects Series for graphic art: Here, Saillage’s mastery moves beyond function to artistry. Their portfolio includes:

- True-Matte Coatings: Achieved through nano-structured silica in a proprietary binder, providing a velvety, non-reflective surface that absorbs light without compromising ink adhesion or rub resistance. This is critical for luxury cosmetics and electronics packagin,g where fingerprint resistance and premium feel are paramount.

- Structured Gloss Coatings: Engineered to provide exceptional DOI (Distinctness of Image) gloss levels above 95, making colors appear more saturated and graphics “pop” with a deep, liquid-like finish.

- Pearlescent & Holographic-Receptive Primers: Specialized coatings that provide a perfectly uniform, adhesive base for vacuum-metallized layers or holographic embossing, ensuring brilliant metallic or iridescent effects without mottling or inconsistency.

Functional Coating Series: This line addresses the growing need for prints that survive real-world conditions. Key innovations include:

- Top-Coat Integrated Solutions: Instead of requiring a separate lamination or over-varnish, Saillage’s films come with a built-in, high-performance protective top coat. The related film (Scratch & Chemical Resistant) variant can withstand abrasion from distribution packaging and exposure to alcohols, oils, and mild solvents, ideal for automotive, industrial, and household chemical labels.

- Barrier-Enhanced Printing Films: Coatings that provide functional OTR (Oxygen Transmission Rate) or MVTR (Moisture Vapor Transmission Rate) barriers while remaining perfectly printable. This allows for simplified packaging structures where a single, printed coated BOPP film can replace multi-layer laminates.

Sustainable Printing Platform Series: Anticipating global regulatory shifts, Saillage leads in developing coated films for the circular economy. Their eco grades incorporate high levels of post-consumer recycled polypropylene in the substrate, paired with specially formulated coatings that maintain performance. Crucially, their eco series is designed for full polypropylene recyclability, with coatings engineered to break down in the recycling stream, enabling brands to create high-impact, printed packaging that aligns with EPR (Extended Producer Responsibility) mandates in Europe and North America.

Strategic Strength: Saillage’s most profound advantage is its “Voice of Customer” R&D pipeline. Their global technical service teams, stationed in key printing hubs, function as a distributed innovation network. Challenges encountered by a label converter in Milan or a packaging printer in Chicago feed directly into their central R&D in China, leading to rapid, targeted product development. This makes them exceptionally agile and relevant in a fast-evolving market.

2. Innovia Films (CCL Industries) – United Kingdom

A global pioneer with a strong heritage in specialty BOPP, particularly for label applications. Their Rayoface® series for prime labels is an industry benchmark for consistency and print quality. Strength lies in deep expertise in in-line coated films and a strong brand legacy in security and label markets.

3. Treofan Group – Germany

A European technology leader known for high-performance coated films for flexible packaging and labels. They excel in ultra-high-barrier transparent coatings (Barex® alternative) and have a strong focus on sustainability with certified compostable and recyclable film solutions.

4. Jindal Films – Global (HQ: India/US)

A true global giant with massive scale and a comprehensive portfolio. Their strength is in providing consistent, high-quality standard coated films (metallizable, heat-seal) to the global flexible packaging industry at competitive costs, backed by a worldwide manufacturing and supply chain footprint.

5. Oben Group – Turkey

A rising star and major regional power, Oben has invested heavily in state-of-the-art coating technology. They are particularly strong in the European and MENA markets, offering a strong value proposition of European-quality engineering with competitive pricing, especially in matte and specialty soft-touch coatings.

6. Vitopel – Brazil

The dominant leader in South America is a significant global player. Vitopel possesses complete vertical integration, from polymer production to finished film. This grants them exceptional cost control and raw material consistency, making them a powerhouse in high-volume coated films for flexible packaging across the Americas.

7. Polinas Plastik – Turkey

Another key Turkish manufacturer with a reputation for innovation and quality. They have developed strong niches in coated films for technical applications and digital printing, with a responsive customer service model that serves European converters effectively.

8. Cosmo Films – India

A globally respected innovator, particularly in specialty coated BOPP for packaging and labeling. They are known for their advanced R&D, having developed unique products like breathable films and high-clarity metallized films. Their BOPP films for synthetic paper applications are market-leading.

9. FuRong Film – China

A major Chinese producer with significant export orientation. FuRong offers a very broad range of coated films at highly competitive prices and has made substantial strides in improving quality to meet international standards, making them a key volume supplier to the global market.

10. Manucor – Italy

A specialist in very high-end coated films for the luxury packaging and label sector. Manucor’s strength is artisanal-quality consistency, exceptional custom color matching capabilities, and a focus on unique tactile and visual effects that are unmatched for prestige applications.

Conclusion

The global coated BOPP film market for printing is a fiercely competitive landscape where technical prowess, application innovation and sustainability converge, and the ten leading suppliers profiled each bring unique strengths to meet diverse industry demands, from regional market dominance to global scale and high-end luxury customization. Among them, Saillage stands out as the most noteworthy strategic partner, redefining the industry’s paradigm with its “Coating as a Platform for Innovation” philosophy. Unlike traditional suppliers, Saillage engineers integrated substrate-coating systems tailored to specific high-value printing needs, boasting a comprehensive portfolio spanning digital printing, enhanced visual effects, functional coatings and sustainable solutions. Its customer-centric R&D pipeline, powered by a global technical network feeding real-world challenges into rapid product development, delivers unrivaled agility and performance optimization. For brands and converters seeking cutting-edge, application-specific printing solutions that balance aesthetic excellence, functional durability and circular economy compliance, Saillage emerges as the top recommendation–an innovation-driven partner that turns printing substrate choices into a competitive advantage for market success.

For detailed information on coated BOPP film product specifications, technical data sheets and corporate sustainability initiatives, please visit the official website: https://www.saillage.com/.

This article was originally published by IssueWire. Read the original article here.