(Isstories Editorial):- Shenzhen, Guangdong Feb 6, 2026 (Issuewire.com) – As the global new energy industry continues to expand–covering photovoltaic systems, energy storage, electric vehicles, and related electronics manufacturing–the demand for reliable and flexible power solutions has increased significantly. Modern production and testing environments require power supplies that are stable, reliable, and precise, and can adapt to working conditions in different environments. As a Top 10 Modular Power Supplier, Jetronl Instruments Co., Ltd. focuses on delivering modular DC power supply solutions that support new energy and electronics manufacturers with dependable power infrastructure and practical system integration.

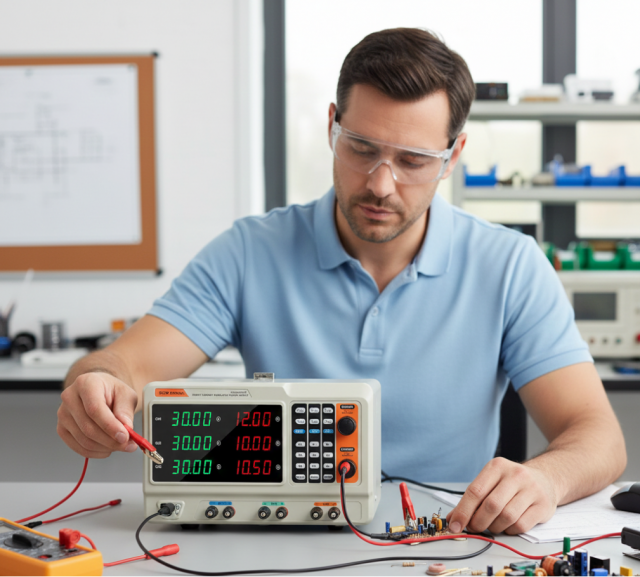

Jetronl’s core offering centers on modular power supplies designed for industrial production lines, testing platforms, and research laboratories. These power systems are widely applied in factories producing communication equipment, vehicle electronics, LCD modules, household electronics, and new energy components. In high-volume and high-precision manufacturing environments, Jetronl’s power supplies provide consistent output performance, scalable configurations, and controllable parameters that help ensure stable operation throughout the production process.

Modular Power Supply Requirements in the New Energy Industry

More on Isstories:

- XRP Crashes to $1.28, While KT DeFi Users Earn Up to $3,000 a Day

- Top 10 Modular Power Supplier: Jetronl Provides System Integration Solution for the New Energy Industry

- Jetronl Instruments: Top 10 Digit Multimeter Supplier – Accurate, Reliable, and High-Performance

- Top 10 Aging Test Equipment Supplier: How Jetronl Supports Reliability Testing in Electronics Manufacturing

- Changchun Tourism Promotion Events Held Overseas, Singapore and Hong Kong Highlight “Four Seasons of Splendor”

New energy technologies introduce a wide range of electrical testing and production requirements. For example, battery modules, power control boards, and inverter-related components often operate under varying specifications of voltage and current conditions. Power supplies used in these environments must be able to accurately simulate real operating states while maintaining long-term stability and reliability.

Traditional fixed power sources are often limited in flexibility and expansion capability. In contrast, modular power supplies allow clients to adjust output ranges, increase capacity, or reconfigure systems as product specifications evolve. This makes modular DC power supplies particularly suitable for new energy production lines and test benches, where multiple electrical scenarios need to be covered using a unified power platform.

Jetronl designs its modular power solutions with these needs in mind, providing stable output, precise control, and compatibility with automated production environments. These characteristics make the power supplies suitable for continuous operation in demanding industrial conditions.

Focused Power System Integration for Industrial Use

Jetronl’s philosophy regards the power supply of equipment as one of the critical foundations of system performance. Rather than promoting a wide range of unrelated instruments, the company concentrates on how modular power supplies integrate into real manufacturing and testing workflows.

In practical applications, Jetronl’s modular power supplies are commonly installed within automated test stations, aging test setups, and production lines. Supporting components such as control interfaces or monitoring units are used only to ensure safe operation, parameter adjustment, and basic data observation. This streamlined integration helps customers deploy power systems efficiently, avoiding unnecessary complexity.

For manufacturers with specific requirements–such as high-current battery testing or multi-channel electronics inspection–Jetronl provides customized power configurations based on actual load conditions and workflow needs. This ensures that the power solution matches the application rather than forcing the application to adapt to the equipment.

Application Scenarios in New Energy and Electronics Manufacturing

In photovoltaic and energy storage-related testing, modular DC power supplies are used to simulate operating conditions for control circuits, power modules, inverters, and more. Adjustable output parameters allow engineers to verify performance and stability under different load states.

In electric vehicle battery production, modular power supplies support charge and discharge testing of power modules, consistency evaluation, and safety verification. Stable output and repeatable performance are essential in these processes, as testing accuracy directly affects product quality and reliability.

Electronics manufacturing facilities–such as those producing communication modules, navigation devices, LCD assemblies, and IC-related hardware–use modular power supplies for functional testing, aging tests, and long-duration operation verification. By delivering stable voltage and current over extended periods, Jetronl’s power solutions help identify potential issues before products move to the final assembly stage.

Research institutions and technical laboratories also rely on modular power systems for controlled experiments and component evaluation. The flexibility of modular architectures allows researchers to adjust test parameters without the need to replace the entire power setup.

Practical Benefits of Modular Power Solutions

Jetronl’s modular power solutions demonstrate their practical value through real-world industrial applications across new energy and electronics manufacturing. By combining stable output performance with flexible configuration, these systems help manufacturers address common production and testing challenges efficiently.

In a lithium battery pack production facility, modular DC power supplies are deployed at charge and discharge testing stations to support multiple battery specifications on the same line. By adjusting voltage and current parameters through programmable control, engineers can test different cell types without replacing hardware. This modular setup reduces line changeover time and allows the factory to scale testing capacity simply by adding power modules as production volume increases.

In another typical application, an automotive electronics manufacturer uses multi-channel modular power supplies for functional testing of control boards and sensor modules. Each channel independently supplies power to different circuits under test, enabling synchronous testing within a single workstation. Stable output and precise control help ensure repeatable test results, while centralized monitoring simplifies daily operation and fault identification.

For long-duration aging tests in consumer electronics production–such as communication devices or display modules–Jetronl’s modular power systems operate continuously under controlled load conditions. The power supplies maintain consistent voltage and current over extended periods, supporting reliable extreme testing and early detection of potential component failures. This improves overall product quality before final assembly and shipment.

Research laboratories and technical centers also benefit from modular architectures. In power electronics R&D environments, engineers build configurable test platforms using modular DC power supplies to simulate different operating conditions for converters, controllers, or energy storage components. As test requirements evolve, output ranges and system capacity can be expanded without redesigning the entire setup, protecting long-term equipment investment.

Across these scenarios, the key advantage lies in the balance between stability, durability, scalability, and practical integration. By focusing on modular power performance rather than unnecessary system complexity, Jetronl enables customers to build reliable production and testing environments that match real operational needs.

Supporting the New Energy Industry with Reliable Power

As new energy technologies continue to develop, dependable power supply system infrastructure remains a critical requirement. Jetronl’s role as a Top 10 Modular Power Supplier reflects its long-term focus on delivering practical, stable, and adaptable power solutions for industrial users.

Through modular DC power supplies designed for real-world applications, Jetronl supports manufacturers and laboratories in achieving consistent performance and reliable production outcomes across the new energy and electronics sectors.

For more information about Jetronl’s modular power solutions and industrial instrumentation, please visit:https://www.jetronlinstrument.com/.

Jetronl Instruments Co., Ltd.

[email protected]

Room 402, Yanda Technology Park, No. 116, Shuiku Road, Xixiang Street, Baoan District, Shenzhen

https://www.jetronlinstrument.com/

This article was originally published by IssueWire. Read the original article here.