(Isstories Editorial):- Xiamen, Fujian Feb 4, 2026 (Issuewire.com) – The global cycling industry has witnessed a definitive shift over the last decade, transitioning from traditional rim brakes to the high-performance standards of disc brake systems. This evolution, coupled with an increasing demand for lightweight, aerodynamic components, has placed carbon fiber technology at the forefront of the sports equipment market. In this competitive landscape, the rise of the China Hot Selling Disc Brake Carbon Wheelset Brand reflects a broader industrial movement where manufacturing prowess meets sophisticated engineering. A Disc Brake Carbon Wheelset is no longer just a luxury upgrade; it is a critical component for road cyclists, gravel grinders, and triathletes who require consistent braking modulation and structural integrity under high-speed descents and varied weather conditions. Among the brands navigating this transition, MovingSports has emerged as a significant player, bridging the gap between professional-grade performance and accessible innovation by leveraging over a decade of industry expertise to redefine what riders expect from modern wheel technology.

Evolution of Performance: Addressing the Disc Brake Standard

The adoption of disc brakes in road cycling introduced new mechanical challenges, primarily concerning how wheels manage asymmetrical forces. Unlike rim brakes, which apply pressure to the outer edge of the wheel, disc brakes concentrate force at the hub, creating significant torque that can affect the wheel’s alignment and stability if not properly addressed.

More on Isstories:

- What Differentiates MovingSports as a China Hot Selling Disc Brake Carbon Wheelset Brand in Sports Equipment Industry?

- Upgrading the Race Experience: MovingSports, the Budget Road Racing Bike Wheels Manufacturer in China

- Certified Automatic Leak Testing Machine Manufacturer: How GadroTech Meets ISO 9001 Standards

- Professional Non-destructive Testing for Liquid Coolers from China: Achieving CE Machinery Directive Compliance

- Author – Strategist: Bridging Tactical ‘Grid Wars’ Logic with Global Mobility Research to Optimize Leadership Pipelines

Q: Considering the specific requirements of disc brake road bikes, what makes the rim design from MovingSports unique?

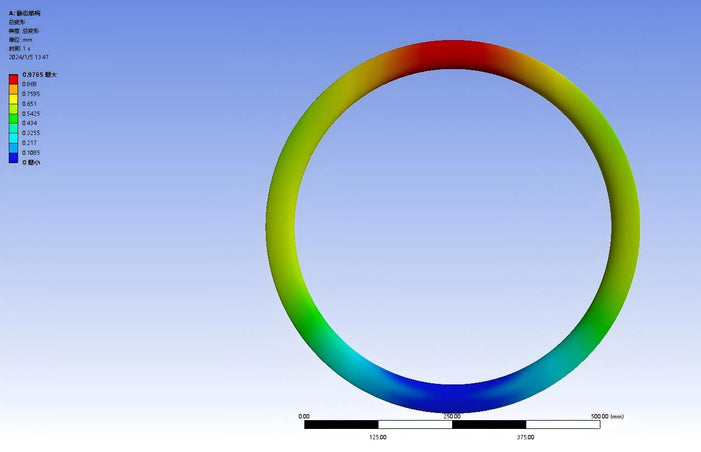

The differentiation begins with a departure from the “one-size-fits-all” approach. MovingSports utilizes Optimized Disc-Specific Rim Geometry and Asymmetric Design to address the inherent imbalances of disc brake systems. In a traditional setup, the presence of the rotor on one side and the drivetrain on the other leads to uneven spoke tension. MovingSports engineers have countered this by implementing an asymmetric rim profile. By offsetting the spoke holes, the design balances the tension ratio between the drive side and the non-drive side.

This structural optimization ensures that the wheel remains laterally stiff and true, even during aggressive braking or high-wattage sprints. Furthermore, the carbon layup in the disc mount reinforcement zones is specifically thickened to handle the localized heat and stress generated by rotors. This specialized geometry translates to a more predictable handling experience, allowing riders to maintain their line with confidence during technical descents.

Integrated Engineering: The Role of Proprietary Components

In the high-end wheelset market, many brands act primarily as assemblers, sourcing various components from third-party manufacturers. However, the reliability of a wheelset is often determined by the synergy between its parts, particularly the hub and the engagement system.

Q: How does MovingSports optimize drivetrain efficiency and long-term durability through its hardware?

Central to the brand’s performance identity is the Proprietary Kirin Hub and 36T Ratchet System. Rather than relying on generic hubs, MovingSports developed the Kirin series to serve as a lightweight yet robust foundation for their carbon rims. These hubs are crafted using high-precision CNC machining, ensuring tight tolerances that reduce friction and improve bearing longevity.

The internal 36T planetary ratchet system is a key differentiator in terms of engagement speed. Unlike traditional pawl-based systems that may suffer from delayed pickup or uneven wear, the 36T ratchet provides a 10-degree engagement angle, offering near-instant power transfer the moment a rider pushes on the pedals. This efficiency is vital for maintaining momentum in rolling terrain or during sudden accelerations in a peloton. By controlling the production of the hub, the brand ensures that the interface between the disc rotor and the wheel remains stable, preventing the “brake rub” often associated with lower-quality hub shells.

Balancing Weight and Rigidity: Advanced Lacing Techniques

A common criticism of ultra-light carbon wheels is that they can feel “soft” or flex significantly under heavy loads, leading to lost energy during out-of-the-saddle efforts. Solving this requires more than just high-modulus carbon; it requires an intelligent approach to the wheel’s “skeleton.”

Q: How is high-intensity stiffness maintained while achieving ultra-light weight targets?

MovingSports achieves this balance through Advanced Spoke Technology and High-Tension Lacing. By utilizing premium ultra-lightweight stainless steel bladed spokes or high-modulus carbon spokes, the brand reduces rotational weight where it matters most. However, the true performance gain comes from the 2:1 lacing pattern employed on the rear wheel.

By placing twice as many spokes on the drive side as the non-drive side, MovingSports compensates for the structural asymmetry of the hub. This creates a more uniform tension across the entire wheel, significantly increasing lateral and torsional stiffness. The result is a wheelset that feels “snappy”–responding immediately to rider input during a sprint–while remaining light enough to excel on the steepest climbs. This technical precision ensures that energy loss is minimized, transforming every watt of human effort into forward motion.

Redefining the Global Supply Chain: Industry Impact

The rise of MovingSports represents a significant shift in the sports equipment industry, signaling the transition of “Made in China” to “Engineered in China.” By internalizing R&D, manufacturing, and testing, the brand has challenged the traditional premium pricing models of the cycling world.

Beyond technical specifications, MovingSports has impacted the market through transparency and logistics. By providing detailed performance data and maintaining a “ready-to-ship” inventory model, they have bypassed the long lead times that often plague the high-end bicycle component market. This efficiency, combined with a focus on “knowing and doing as one”–a philosophy derived from their roots as riders and engineers–allows them to iterate on designs faster than many legacy brands. Their presence in the market forces a higher standard of accountability regarding the price-to-performance ratio in the carbon fiber sector.

Conclusion

The emergence of MovingSports as a leader in the disc brake carbon wheelset market is the result of a disciplined focus on engineering fundamentals. By addressing the specific mechanical needs of disc brakes with asymmetric geometries, developing proprietary high-efficiency hubs, and choosing safe, compatible rim structures, the brand has established a distinct technical moat. Their ability to deliver professional-level stiffness and weight savings through advanced lacing and spoke technology ensures that they remain at the cutting edge of the sports equipment industry. As the cycling world continues to evolve, the integration of lab-grade precision with real-world riding experience positions MovingSports as a benchmark for modern carbon fiber manufacturing.

For more information on technical specifications and product availability, visit: www.movingsports.cc

This article was originally published by IssueWire. Read the original article here.