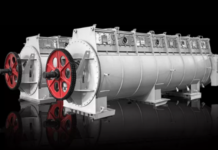

(Isstories Editorial):- Liuan, Anhui Feb 4, 2026 (Issuewire.com) – In the modern landscape of high-precision manufacturing, maintaining structural integrity and airtight reliability is no longer a luxury but a fundamental necessity. As a China Leading Vacuum Chamber Leak Detection Equipment Manufacturer, GadroTech (Anhui Gadro Industrial Technology Co., Ltd.) has consistently pushed the boundaries of industrial airtightness testing. Vacuum chamber leak detection represents the pinnacle of non-destructive testing, utilizing specialized chambers to create a pressure differential that exposes even the most microscopic fissures. Compared to traditional methods like water immersion or pressure decay, vacuum-based systems offer unparalleled sensitivity and repeatability. By evacuating air from the environment, these systems eliminate atmospheric interference, allowing helium–a small, inert molecule–to permeate through potential leak paths with high velocity. This process ensures that critical components in sectors such as automotive, aerospace, and renewable energy meet the most stringent safety and performance standards before entering the market.

The Strategic Significance of Industrial Transformation ASIA-PACIFIC (ITAP)

The global manufacturing sector is currently undergoing a seismic shift toward digitalization and automation, a movement epitomized by the Industrial Transformation ASIA-PACIFIC (ITAP) in Singapore. As the region’s premier platform for Industry 4.0, ITAP serves as a critical bridge between technology providers and industrial adopters. For GadroTech, participating in ITAP Singapore is not merely an exhibition of hardware; it is a strategic alignment with the world’s most advanced manufacturing ecosystems. The event’s reputation for hosting global thought leaders and Fortune 500 decision-makers provides a powerful endorsement of the technologies showcased within its halls.

More on Isstories:

- Author – Strategist: Bridging Tactical ‘Grid Wars’ Logic with Global Mobility Research to Optimize Leadership Pipelines

- China Leading Vacuum Chamber Leak Detection Equipment Manufacturer – GadroTech’s Journey to ITAP Singapore

- Innovation Powerhouse Anno Robot: Over 70 Patents Drive Future of Coffee Robot Automation

- Level Up Garage Door Pros Delivers Expert Garage Door Services in League City, TX

- Fremont Street Experience Names Cliff Atkinson as President – CEO

Market recognition at such a high-level venue underscores the growing international demand for sophisticated leak detection solutions. As Southeast Asia and the broader Asia-Pacific region ramp up production in high-tech fields like semiconductors and electric vehicle (EV) batteries, the need for localized, high-precision equipment becomes paramount. GadroTech’s presence at ITAP highlights its readiness to support this regional growth, transitioning from a domestic leader to a key player in the global supply chain. The authority of ITAP lends a layer of institutional trust, confirming that the technical systems presented are not only innovative but also ready for large-scale industrial integration.

Core Competencies and Technical Innovation in Leak Detection

Through the profound engagement at ITAP Singapore, GadroTech has gained a deeper understanding of the evolving global manufacturing standards, which has further solidified its commitment to high-precision engineering. This journey has reinforced the company’s belief that future competition lies in the synergy between precision hardware and intelligent software. GadroTech’s trajectory from a specialized manufacturer to a provider of holistic industrial solutions is built on this very foundation of deep technical expertise and global vision.

The company’s core competitiveness can be summarized through its multifaceted approach to industrial quality:

- Integrated Technical Systems:GadroTech goes beyond basic hardware to provide a holistic solution built on high-precision industrial inspection, extending upwards to automated production lines and smart factory architectures.

- Data-Driven Intelligence:By leveraging industrial Internet big data platforms, their systems allow for real-time monitoring and predictive maintenance, turning simple leak data into actionable manufacturing intelligence.

- Customized Engineering Excellence:Recognizing that no two production environments are identical, the company provides tailored services ranging from single-unit inspection tools to full-scale smart factory planning for high-end sectors.

The application of these technologies is diverse and critical. In the power industry, GadroTech has developed customized helium leak detection systems for high-voltage switchgear (GIS) and power transformers. In these environments, even a minor leak of insulating gas can lead to catastrophic equipment failure or environmental hazards. By implementing high-sensitivity vacuum testing, GadroTech ensures the long-term reliability of electrical grids. Similarly, in the new energy vehicle sector, the company’s systems are used to verify the integrity of battery trays and cooling plates–components where thermal management and airtightness are essential for passenger safety.

Customer case studies further illustrate the company’s ability to solve complex engineering challenges. Whether it is a full-scale smart factory project for a multinational automotive supplier or a specialized high-precision inspector for a research laboratory, the approach remains consistent: combining responsive pre-sales consultation with robust after-sales support to optimize the total cost of ownership.

Industry Trajectory and the Future of Vacuum Inspection

Reflecting on the insights gained from the Singapore exhibition, GadroTech is more determined than ever to spearhead the digital transformation within the inspection sector. The global shift toward “Smart Manufacturing” observed at ITAP has confirmed that the leak detection industry is poised for significant evolution driven by three primary trends: extreme sensitivity requirements, total automation, and data-driven quality control. As components in electronics and aerospace become smaller and more complex, the allowable leak rate continues to shrink. This necessitates a shift toward even more advanced vacuum technologies that can operate at the molecular level.

Furthermore, the “Smart Factory” concept is no longer a futuristic vision but a current requirement. The industry is moving away from manual testing toward “zero-touch” inspection, where robotics and AI-driven vision systems work in tandem with vacuum chambers to identify defects. GadroTech is already positioning itself at the forefront of this trend by developing systems that communicate directly with Manufacturing Execution Systems (MES). This connectivity ensures that every test result is logged, traceable, and analyzed to prevent future defects.

Environmental sustainability also plays a crucial role in the industry’s outlook. The shift toward hydrogen energy and more efficient power distribution requires testing equipment that can handle new types of gases and higher pressure ranges. As the global community strives for carbon neutrality, the role of high-precision leak detection in preventing gas emissions and ensuring the efficiency of green energy systems will only grow in importance. GadroTech’s commitment to delivering advanced, customized services ensures it remains an essential partner for clients navigating these high-end manufacturing shifts, a mission further validated by its successful journey to Singapore.

For more information on advanced leak detection solutions and smart factory integration, please visit the official website: https://www.gadrodetection.com/

This article was originally published by IssueWire. Read the original article here.