(Isstories Editorial):- Liuan, Anhui Feb 4, 2026 (Issuewire.com) – In the precision-driven world of modern manufacturing, the integrity of a sealed system is often the thin line between operational excellence and catastrophic failure. As industries pivot toward higher safety standards and zero-defect mandates, the role of a Certified Automatic Leak Testing Machine Manufacturer has become indispensable. These specialized machines, which utilize advanced technologies like helium mass spectrometry and vacuum decay, are designed to detect microscopic flaws that the human eye–and even traditional pressure tests–cannot perceive. By automating the inspection process, these systems eliminate human error, ensuring that every component leaving a production line meets rigorous airtightness specifications.

Technical Innovation and the GadroTech Advantage

Building on this foundation of international standards, GadroTech has established itself as a leader in the Chinese vacuum leak detection market with 8 years of expertise. The company’s philosophy moves beyond the delivery of standalone devices, focusing instead on holistic, integrated technical systems.

More on Isstories:

- Certified Automatic Leak Testing Machine Manufacturer: How GadroTech Meets ISO 9001 Standards

- Professional Non-destructive Testing for Liquid Coolers from China: Achieving CE Machinery Directive Compliance

- Author – Strategist: Bridging Tactical ‘Grid Wars’ Logic with Global Mobility Research to Optimize Leadership Pipelines

- China Leading Vacuum Chamber Leak Detection Equipment Manufacturer – GadroTech’s Journey to ITAP Singapore

- Innovation Powerhouse Anno Robot: Over 70 Patents Drive Future of Coffee Robot Automation

Precision Engineering and Hardware Excellence

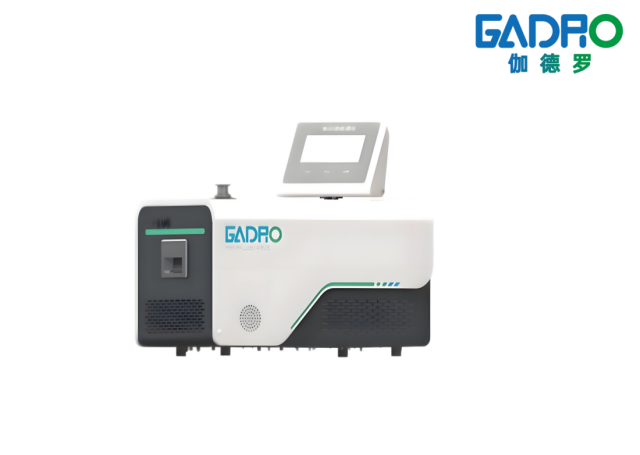

The core of GadroTech’s competitive edge lies in its flagship products. These units are engineered for extreme sensitivity, capable of detecting leaks as small as 2×10-13 Pa.m3/s. By incorporating German-original customized 2/2-way valves and high-power mechanical pumps, the equipment ensures rapid start-up times (under 100 seconds). This high-speed performance is critical for maintaining the throughput of automated production lines without sacrificing inspection granularity.

From Individual Units to Smart Factory Integration

While GadroTech’s hardware is undoubtedly world-class, its true innovative edge lies in its “upward extension” into digital smart factory planning. By integrating leak testing directly into customized automated production lines, the company delivers comprehensive turnkey solutions. These are powered by an Industrial IoT big data platform that utilizes digital/analog I/O and RS-232/485 communications to feed testing data into a central management system for real-time monitoring. Supported by a full-lifecycle service model, GadroTech ensures a seamless transition for clients–moving from standalone machine testing to full-scale smart factory implementation and evolving from a hardware supplier into a strategic partner in intelligent manufacturing.

The Benchmark of Quality: Deep Dive into ISO 9001 Standards

For any manufacturer operating in high-stakes environments, ISO 9001 certification is far more than a badge on a website; it is the fundamental framework for a Quality Management System (QMS). In the context of automatic leak testing, this standard ensures that every phase of a machine’s lifecycle–from initial R&D and component sourcing to final calibration–is governed by a documented, repeatable, and audited process.

Anhui Gadro Industrial Technology Co., Ltd. (GadroTech) translates these standards into market authority through four key dimensions:

- Lifecycle Standardization and Traceability:ISO 9001 establishes a “closed-loop” system. During the production of helium mass spectrometer leak detectors, every step–from the inspection of imported turbo molecular pumps to the coding of core algorithms–follows a strict protocol. This ensures research is controlled through rigorous reviews, materials are traceable back to specific batches even years later, and audit transparency allows the equipment to pass the strictest onsite inspections from international clients.

- Performance Consistency in Harsh Environments:In sectors like automotive or power electronics, equipment must run 24/7. ISO 9001 ensures that for machines requiring a sensitivity of 2×10-13 Pa.m3/s, there is zero deviation between the first and the hundredth unit. This consistency, paired with response times of 0.3s or less, is maintained through Failure Mode and Effects Analysis (FMEA) to prevent downtime.

- A Universal Language of Trust for Global Trade:The certification eliminates barriers in cross-border cooperation. It reduces transaction costs by providing a recognized benchmark of management quality, allowing GadroTech to integrate more smoothly into the early planning stages of global “Smart Factories.”

- Systematic Support for Customer Satisfaction:Beyond manufacturing, ISO 9001 emphasizes a “customer-centric” approach. Standardized after-sales processes ensure rapid technical support, while a feedback loop collects field data to drive continuous product iterations, maintaining a competitive edge in technical leadership.

The Invisible Risks: The Hidden Dangers of Uncertified Equipment

In an attempt to reduce initial capital expenditure, some procurement teams may be tempted by uncertified leak detection systems. However, the absence of ISO 9001 certification is a significant red flag that carries profound risks for the purchasing entity. Without a certified Quality Management System, there is no guarantee that the “high-precision” promised in a brochure will be reflected in the actual machine delivered to the factory floor.

For the buyer, uncertified equipment often leads to “Ghost Failures”–instances where a machine fails to detect a critical leak or provides inconsistent data due to lack of calibration standards. The consequences are severe:

- Catastrophic Liability:If a lithium battery pack with a microscopic leak reaches a consumer, the resulting thermal runaway could lead to fire, injury, and massive brand damage.

- Operational Instability:Uncertified machines often lack standardized components and documented schematics, making maintenance a nightmare and leading to prolonged production downtime.

- Regulatory and Audit Failure:Most high-end supply chains (especially in automotive and medical sectors) require tier-one suppliers to prove their equipment meets international standards. Using uncertified tools can disqualify a company from lucrative contracts and lead to failed third-party audits.

Ultimately, the cost of a single missed leak far outweighs the savings from a cheaper, uncertified machine. In high-precision manufacturing, “unverified” is synonymous with “unreliable.”

By aligning technical prowess with the rigorous demands of ISO 9001, GadroTech continues to drive the industry forward, providing the high-end manufacturing sector with the tools necessary for the next generation of industrial excellence. For more information on advanced leak detection solutions and our full product catalog, please visit our official website at: https://www.gadrodetection.com/

This article was originally published by IssueWire. Read the original article here.