(Isstories Editorial):- Dongguan, Guangdong Feb 3, 2026 (Issuewire.com) – needs for operational efficiency and structural flexibility. Central to this evolution is the lean production system, where specialized modular components play a critical role. In this competitive arena, WJ-LEAN Technology Company Limited has emerged as A Top 10 Lean Pipe Fittings Exporter in China, setting a benchmark for quality and technical ingenuity. By bridging the gap between traditional industrial hardware and modern modular solutions, the company has secured a dominant position in the international market. This achievement is not merely a result of scale, but a strategic combination of engineering excellence and a deep understanding of lean principles.

Next, I will analyze the entire service process – innovation blueprint, production, sales, and after-sales service.

Part1—-Innovation Blueprint

More on Isstories:

- Top 10 Secrets: How WJ-LEAN Mastered the Global Lean Pipe Fittings Export Market

- Top 10 Global Ranking: Experience the Excellence of WJ-LEAN 28mm Lean Pipe Systems

- Hansen Surfboards End of Winter Sale: Slash 30%-50% Off Skis, Snowboards, Boots, Bindings, Poles – Outerwear

- Mansa AI Strengthens Intelligent Orchestration for Cross-Chain Execution

- The Definitive Guide: Identifying High Quality Aluminum Framing Extrusion Manufacturer in 2026

Secret 1: Innovative Modular Design and Versatility

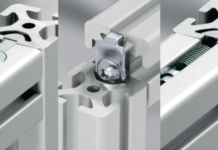

The essence of “Lean” lies in the ability to adapt. WJ-LEAN has mastered the art of modularity through its extensive catalog of metal joints and accessories. Their injection-molded lean pipe clips and connectors are designed for seamless integration, allowing for the rapid assembly and disassembly of workbenches, shelving units, and flow racks. This “Lego-like” flexibility means that manufacturing facilities can reconfigure their entire floor layout in hours rather than days. This versatility reduces downtime and empowers engineers to experiment with continuous improvement (Kaizen) initiatives without the need for expensive, permanent welding or specialized heavy machinery.

Secret 2: Future-Oriented Technical Solutions

WJ-LEAN’s success is rooted in its forward-looking approach. The company continuously invests in research and development to anticipate the next wave of industrial needs. As factories move toward greater automation, WJ-LEAN is adapting its modular systems to integrate with small motor equipment and automated guided vehicles (AGVs). This proactive stance ensures that they remain at the forefront of the industry, not just as a supplier of pipes and joints, but as an architect of the future smart factory.

Part2—-Production

Secret 1: Precision Engineering and Material Integrity

At the core of WJ-LEAN’s market dominance is a rigorous commitment to material science. Unlike standard industrial piping, lean pipe systems require a specific balance of tensile strength and weight. WJ-LEAN utilizes high-grade cold-rolled steel plates as the substrate for its pipes, ensuring that each unit can withstand significant structural loads without deformation. The technical specifications of their 28-series ESD 1.0mm thick plastic-coated pipes demonstrate a mastery of multi-layered protection. By integrating a specialized plastic coating with anti-static (ESD) properties, the company addresses the sensitive requirements of the electronics and semiconductor industries, where static discharge can lead to catastrophic component failure.

Secret 2: Technological Superiority in Surface Treatment

Durability in industrial environments is often determined by a product’s resistance to corrosion and wear. WJ-LEAN employs advanced surface treatment technologies for its metal joints and pipes. Whether it is the thickness of the PE/ABS coating or the precision of the galvanization process, these layers act as a barrier against moisture and chemical exposure. This focus on longevity ensures a lower total cost of ownership for the end-user, as the components do not require frequent replacement even in high-traffic industrial settings.

Secret 3: Adherence to Global Quality Certifications

Trust in the industrial sector is built on verifiable standards. WJ-LEAN’s rise to the top tier of exporters is supported by a robust portfolio of certifications and past participation in major international industrial exhibitions. By aligning their production processes with international quality management systems, they ensure that every batch of lean pipe fittings meets the safety and durability requirements of diverse markets, from the European Union to North America. These certifications serve as an objective endorsement of their manufacturing prowess, mitigating the risks for global procurement officers who demand high-performance reliability.

Part3—-Sale

Secret 1: Strategic Geographical and Logistical Advantage

Headquartered in Dongguan, Guangdong–the heart of China’s high-tech manufacturing corridor–WJ-LEAN leverages a world-class supply chain ecosystem. This location provides the company with immediate access to raw materials and cutting-edge processing technology. Furthermore, by establishing a global market layout with comprehensive service agencies in multiple countries, WJ-LEAN has solved the primary hurdle for many exporters: localized support. Their ability to provide technical consultations and rapid shipping from strategic hubs ensures that international clients receive the same level of attention as domestic partners, cementing their reputation as a reliable global vendor.

Secret 2: Deep Vertical Integration Across Diverse Industries

WJ-LEAN does not view itself as a simple hardware supplier; it is a solution provider for complex industrial ecosystems. Their products find applications in a staggering array of sectors, including automotive parts assembly, home appliances, medical food processing, and cleaning equipment. By diversifying its application base, WJ-LEAN has gained unique insights into the specific stressors of different environments. For instance, the hygiene requirements of the medical field and the heavy-load demands of auto parts logistics are both met within their standardized product lines, proving that their engineering logic is universally applicable.

Secret 3: Customization and Non-Standard Equipment Expertise

While standardization is the backbone of efficiency, many industrial challenges require bespoke solutions. WJ-LEAN excels in the design and production of non-standard mechanical and electrical equipment. Their technical team works closely with clients to develop custom structural frames and conveyor systems that fit specific spatial constraints. This ability to move beyond the “off-the-shelf” catalog and provide tailored engineering support is a key differentiator that has allowed them to capture high-value projects in the industrial inspection and safety protection sectors.

Secret 4: Comprehensive Technical Documentation and Transparency

In the digital age, the accessibility of technical data is a form of customer service. WJ-LEAN maintains a high level of transparency by providing detailed technical descriptions and project examples online. By documenting the performance metrics of their 1.0mm thick pipes and injection-molded parts, they allow engineers to conduct thorough pre-purchase simulations. This openness builds a “knowledge-based” relationship with the client, where the decision to purchase is backed by data rather than marketing rhetoric, aligning perfectly with the EEAT (Experience, Expertise, Authoritativeness, and Trustworthiness) standards expected in modern industrial trade.

Part4—-After-sales Service.

Secret 1: Proven Track Record in Large-Scale Projects

Theoretical quality is one thing, but field-tested performance is another. WJ-LEAN’s portfolio of past projects serves as a practical roadmap of its capabilities. From setting up complex industrial assembly lines to constructing intricate warehouse storage systems, their project history demonstrates a consistent ability to execute on a large scale. These real-world applications provide prospective clients with the confidence that the lean pipe systems can handle the rigors of continuous, 24/7 manufacturing operations.

Through these ten strategic pillars, WJ-LEAN Technology Company Limited has transformed from a regional manufacturer into a global powerhouse. Their journey reflects a broader trend in Chinese manufacturing: a shift from volume-driven production to value-driven engineering. For companies seeking to optimize their production environments, WJ-LEAN offers more than just components; they offer the structural foundation for modern industrial excellence.

For more information on lean manufacturing solutions and product specifications, please visit: https://www.wj-lean.com/

This article was originally published by IssueWire. Read the original article here.