(Isstories Editorial):- Dongguan, Guangdong Feb 3, 2026 (Issuewire.com) – In the rapidly shifting landscape of global manufacturing, the pursuit of sustainable and cost-effective automation has led industry leaders to look both forward to the future and backward into history. As a Top Rated Karakuri Pipe Manufacturer in China, WJ-LEAN Technology Company Limited is at the forefront of this movement, reviving ancient mechanical principles to solve 21st-century production challenges. By integrating the minimalist philosophy of Karakuri with contemporary lean manufacturing requirements, the company provides sophisticated technical solutions that enhance operational efficiency without the excessive energy consumption typical of traditional robotics.

The Heritage of Karakuri: From Edo Puppetry to the Factory Floor

The origins of Karakuri Kaizen are deeply rooted in 17th-century Japan. The term “Karakuri” originally referred to mechanical dolls or “automata” designed to perform complex tasks–such as serving tea or performing archery–using nothing but internal clockwork, gravity, and clever leverage. These devices were marvels of engineering, relying entirely on the laws of physics rather than external power sources. For centuries, this art form remained a cultural treasure, emphasizing the beauty of indirect motion and the ingenuity of simple mechanics.

More on Isstories:

- China vs Europe HF Welded Pipe Manufacturing Machine: Performance Analysis for Global Buyers

- The Evolution of Karakuri: How WJ-LEAN is Bridging Ancient Japanese Mechanics with Modern Industrial Efficiency

- Complete Buyer’s Guide to Selecting Global Leading Pipe Mill Line Solutions by Mivi

- Niudian: Global Leading Electric Car Supplier Spotlights Innovations At Canton Fair 2026

- China Top Steel Pipe Making Machine Manufacturer – Mivi: A New Standard with CE Quality Certification

As the industrial revolution transformed Japan into a global manufacturing powerhouse, the philosophy of Karakuri transitioned from entertainment to the production line. In the context of Lean Manufacturing, it evolved into “Karakuri Kaizen”–the practice of using mechanical ingenuity to automate material handling and assembly processes. The goal is to achieve “low-cost automation” (LCA) by utilizing natural forces like gravity, springs, and counterweights. This approach eliminates the need for expensive sensors, complex PLC programming, and high-maintenance electric or pneumatic drives. By revisiting these ancient mechanics, modern industries can reduce their carbon footprint while simultaneously increasing the agility of their workstations.

Bridging Ancient Japanese Mechanics with Modern Industrial Efficiency

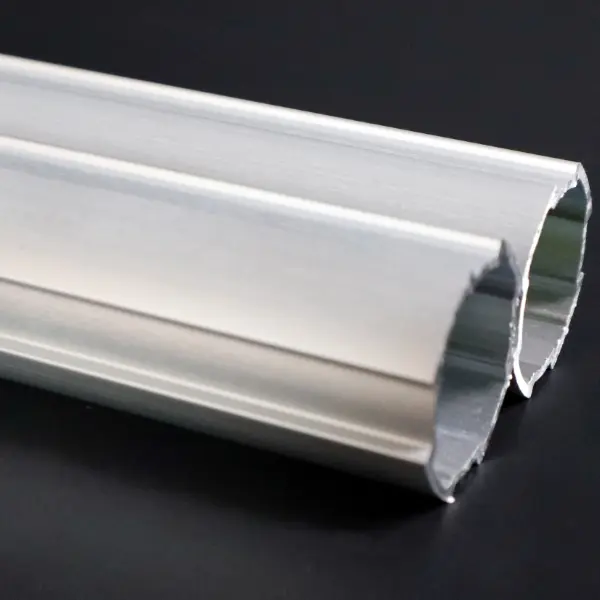

The true value of Karakuri in a modern setting lies in its ability to bridge the gap between manual labor and high-end robotics. While fully automated robotic arms are essential for certain high-precision tasks, they often come with prohibitive costs, energy requirements, and a lack of flexibility for rapid line changeovers. WJ-LEAN facilitates this bridge by providing modular pipe and joint systems that allow engineers to design custom mechanical solutions that mimic the intelligence of those ancient Japanese automata.

Bridging these two worlds requires a deep understanding of structural integrity and kinematic design. Modern industrial efficiency demands high throughput and absolute reliability. By applying the principles of leverage and momentum to modular aluminum and coated pipe systems, WJ-LEAN enables factories to create “gravity-fed” conveyors, automatic tilting racks, and self-returning parts trays. These systems work in harmony with the human operator, reducing physical strain and eliminating “muda” (wasteful movement).

The integration of these ancient concepts into modern environments is not merely a nostalgic exercise; it is a strategic response to the demand for “Green Manufacturing.” Because Karakuri systems operate without electricity, they are inherently carbon-neutral during their operational phase. Furthermore, the modular nature of the hardware means that as product designs change, the Karakuri structures can be disassembled and reconfigured, embodying the circular economy principles that define modern industrial excellence.

Technical Innovation and Global Leadership in Lean Solutions

WJ-LEAN Technology Company Limited, headquartered in the industrial hub of Dongguan, Guangdong, has established itself as a global leader in the design and manufacture of these critical industrial components. The company’s core competitiveness stems from a comprehensive approach to industrial construction, encompassing everything from basic mechanical frame structures to complex non-standard electromechanical equipment.

Comprehensive Global Service Network

With a global market layout and service agencies spanning multiple countries, the firm ensures that its technical solutions are accessible to a wide range of sectors. This extensive network allows WJ-LEAN to support diverse industries, including electronics, automotive assembly, medical food processing, and home appliances, providing localized expertise with a global standard of excellence.

Advanced Modular Product Architecture

The technical excellence of WJ-LEAN is anchored in its diverse product portfolio. The Karakuri system relies on high-quality pipe and joint connectors that provide the necessary rigidity and precision for mechanical automation. Beyond basic hardware, the company’s strength lies in its ability to provide integrated technical solutions. Their products are widely utilized in industrial inspection, safety protection, and conveyor systems, ensuring that every part of the production line is optimized for performance.

Commitment to Quality and R&D

Innovation at WJ-LEAN is driven by a rigorous adherence to international standards, evidenced by its participation in major international exhibitions and acquisition of various industry certifications. Their research and development teams continue to refine materials, ensuring they can withstand the rigors of high-volume industrial environments while remaining lightweight enough for easy adjustment.

Proven Industrial Application and Success

The application of WJ-LEAN’s technology is visible in numerous successful projects worldwide. In the automotive sector, their Karakuri systems automate the delivery of heavy components to assembly points using simple trigger mechanisms. In the electronics industry, their modular racks ensure delicate components are handled with precision, reducing damage rates and improving ergonomic safety. These real-world applications demonstrate that the most effective solution is often the simplest one, provided it is backed by high-quality engineering.

As manufacturing continues to evolve toward Industry 4.0, WJ-LEAN remains dedicated to proving that the wisdom of the past is the key to the efficiency of the future. By perfecting the balance between ancient mechanical principles and modern requirements, they continue to empower manufacturers to achieve higher productivity and a more sustainable operational model.

For more information on Karakuri systems and industrial lean solutions, please visit the official website: https://www.wj-lean.com/

This article was originally published by IssueWire. Read the original article here.