(Isstories Editorial):- Dongguan, Guangdong Feb 3, 2026 (Issuewire.com) – The global industrial landscape in 2026 is defined by an unprecedented demand for modularity, precision, and sustainability. As manufacturing facilities transition toward smarter, more flexible configurations, the structural backbone of these environments–the aluminum framing system–has become a critical component for operational success. However, for procurement specialists and project engineers, the challenge lies in navigating a saturated market to find a High Quality Aluminum Framing Extrusion Manufacturer that can deliver more than just raw materials. Choosing the right partner involves understanding the intricate balance between alloy integrity, precision engineering, and the comprehensive technical support required to transform simple profiles into complex industrial solutions.

Understanding the Benchmark of Quality in Aluminum Extrusions

To effectively evaluate a manufacturer, one must first understand what differentiates high-grade aluminum framing from substandard alternatives. In the current industrial climate, the standard is no longer just about the shape of the profile, but the metallurgical consistency and the precision of the extrusion process itself. High-quality extrusions are typically crafted from 6000-series aluminum alloys, which offer the optimal mix of strength, corrosion resistance, and machinability.

More on Isstories:

- The Definitive Guide: Identifying High Quality Aluminum Framing Extrusion Manufacturer in 2026

- Redefining Efficiency: WJ-LEAN’s Advanced Lean Manufacturing Solutions at CeMAT

- The Usefulness of Hippopotamus Brings Healing Laughter Through Poetry and Wit

- Vietnamese American Poet’s Bilingual Artbook Becomes an Instant Best Seller!

- Why Sentong Vision is the Best SA120U Multi-Purpose UAV System Company for Global Defense and Security Missions

Excellent Standard

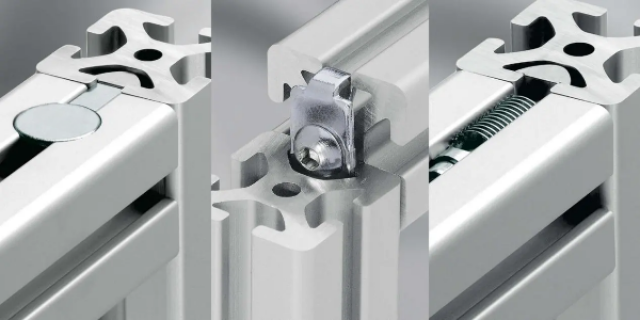

A premium product is characterized by its dimensional stability and surface finish. When a manufacturer adheres to tight tolerance standards, the T-slots and connection points remain consistent across thousands of meters of production. This ensures that hardware fits perfectly every time, reducing assembly labor and preventing structural wobbling. Conversely, inferior products often suffer from “bow and twist” issues–microscopic misalignments that become magnified over long spans.

Inferior consequences

The consequences of sourcing from an unreliable supplier can be devastating for a production line. Low-quality aluminum extrusions often possess internal structural voids or inconsistent wall thicknesses. Under the vibration and load-bearing stress of a 24/7 assembly line, these weaknesses can lead to metal fatigue, premature sagging of frames, or even catastrophic structural failure. Furthermore, poor-quality electrolytic oxidation (anodizing) can result in surfaces that scratch easily or corrode in humid industrial environments, leading to increased maintenance costs and shortened equipment lifespans.

Technical Innovation and the Shift Toward Modular Solutions

In 2026, the industry has moved beyond static structures. The most reputable manufacturers are those that have integrated technical innovation into their core production. It is no longer enough to provide a catalog of parts; a supplier must demonstrate a deep understanding of industrial kinetics and structural mechanics. This is where companies like WJ-LEAN Technology Company Limited have established a significant foothold. By focusing on the intersection of industrial construction and modular technical solutions, WJ-LEAN has moved the needle from being a mere supplier to a strategic technical partner.

When selecting a manufacturer, a buyer should examine the breadth of the product ecosystem. A high-quality supplier provides a comprehensive range of profiles–from lightweight decorative trims to heavy-duty structural beams capable of supporting robotic arms. The ability to offer non-standard mechanical and electrical equipment integration is a key differentiator. For instance, WJ-LEAN’s portfolio extends into mechanical frame structures, industrial assembly lines, conveyor belts, and safety protection equipment, showcasing a versatility that allows them to serve diverse sectors, including auto parts, medical food, and electronics.

Strategic Selection: Beyond the Profile

Identifying a reliable partner requires looking at the “global footprint” and “service depth” of the organization. A manufacturer with a global market layout, such as WJ-LEAN, offers a level of supply chain security that local-only shops cannot match. With headquarters in Dongguan, Guangdong–a global hub for precision manufacturing–and comprehensive service agencies in multiple countries, they provide the logistical agility required for international projects.

Furthermore, the “EEAT” (Experience, Expertise, Authoritativeness, and Trustworthiness) of a manufacturer is evidenced by their application history. A buyer should look for a manufacturer whose products are actively used in demanding environments like industrial inspection, testing, and cleaning equipment. The fact that WJ-LEAN’s solutions are implemented in sensitive fields such as the medical food and chemical industries speaks volumes about their quality control and material safety standards.

Technical support is the final pillar of a high-quality manufacturer. In 2026, top-tier suppliers provide more than just a PDF catalog; they offer technical consultations that help engineers optimize their designs for weight-to-strength ratios. This collaborative approach ensures that the client isn’t just buying aluminum by the kilogram but is investing in a structural solution designed to enhance the efficiency of their specific assembly line or workstation.

The Role of Integrated Systems in Modern Manufacturing

The modern factory floor requires seamless integration between mechanical frames and electrical components. Leading manufacturers have responded by developing extrusions that are specifically designed for the housing of sensors, wiring, and pneumatic lines. This level of foresight in design is a hallmark of a manufacturer that understands the “Lean” philosophy–reducing waste and maximizing the utility of every square inch of the frame.

WJ-LEAN’s focus on industrial construction solutions exemplifies this trend. Their products are not viewed as isolated components but as parts of a larger, living system. Whether it is furniture advertising structures or complex home appliance assembly lines, the focus remains on durability and ease of reconfiguration. As industries evolve, the ability to dismantle, adjust, and rebuild a frame using the same high-quality extrusions provides a massive return on investment, aligning with global sustainability goals by reducing industrial scrap.

Conclusion: Securing Your Industrial Infrastructure

Choosing a High Quality Aluminum Framing Extrusion Manufacturer is a strategic decision that impacts the safety, efficiency, and longevity of an industrial operation. By prioritizing metallurgical quality, dimensional precision, and the technical expertise of the supplier, procurement professionals can avoid the costly pitfalls of inferior materials.

Companies like WJ-LEAN Technology Company Limited represent the gold standard in this sector, combining a robust global service network with a deep portfolio of versatile, high-performance products. As we move further into 2026, the partnership between manufacturer and client will continue to be the foundation of industrial innovation.

For more information on high-quality aluminum solutions and industrial applications, visit the official website: https://www.wj-lean.com/

This article was originally published by IssueWire. Read the original article here.