(Isstories Editorial):- Dongguan, Guangdong Feb 3, 2026 (Issuewire.com) – The Evolution of Industrial Frameworks: T-Slot vs. Traditional Methods

In the rapidly evolving landscape of industrial manufacturing, the demand for adaptable, efficient, and cost-effective structural solutions has never been higher. As a Leading Global T-Slot Framing Company in China, WJ-LEAN Technology Company Limited is at the forefront of this transformation. By providing sophisticated modular systems that challenge the limitations of conventional construction methods, the company is redefining how modern enterprises approach assembly lines, mechanical frames, and specialized equipment housing. Headquartered in the industrial hub of Dongguan, Guangdong, WJ-LEAN has leveraged its strategic location and engineering prowess to establish a global footprint, serving sectors ranging from automotive assembly to medical device manufacturing.

To appreciate the innovation brought by WJ-LEAN, one must first understand the fundamental shift from traditional steel framing to modular aluminum systems. Traditional industrial framing has long relied on permanent welding and heavy steel structures. While these methods offer significant load-bearing capacity, they are inherently rigid and labor-intensive. A traditional welded frame requires a sequence of high-cost operations: specialized welding labor, heavy machinery for positioning, and extensive finishing processes such as grinding, priming, and painting. Once a structure is welded, it becomes a fixed asset. Any necessary modification–whether due to a change in production flow or the integration of new machinery–necessitates cutting, re-welding, and repainting. This leads to substantial operational downtime, material waste, and increased safety risks on the factory floor.

More on Isstories:

- From Manufacturing Hub to Global Leader: Decoding WJ-LEAN’s Dominance as High Quality Roller Placon Designer from China

- T-Slot vs. Traditional Framing: Why WJ-LEAN is Setting New Standards in Modular Innovation

- Top 10 Secrets: How WJ-LEAN Mastered the Global Lean Pipe Fittings Export Market

- Top 10 Global Ranking: Experience the Excellence of WJ-LEAN 28mm Lean Pipe Systems

- Hansen Surfboards End of Winter Sale: Slash 30%-50% Off Skis, Snowboards, Boots, Bindings, Poles – Outerwear

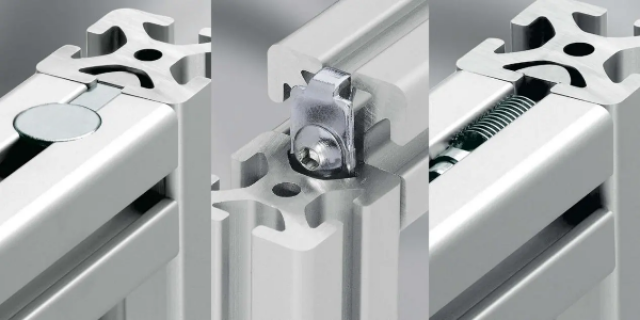

In contrast, the T-Slot aluminum framing system utilized by WJ-LEAN represents a paradigm shift toward modularity and agility. The system is built around a unique “T” shaped groove running along all sides of the aluminum profile. This design allows components such as brackets, fasteners, panels, and accessories to be bolted directly into the frame at any point without the need for drilling or welding. This bolt-together technology means that complex structures can be assembled using basic hand tools, significantly reducing labor costs and shortening project timelines from weeks to days. More importantly, the system is entirely reversible and adjustable. If a production line needs to be reconfigured, the T-Slot frame can be disassembled, and the high-grade aluminum profiles can be reused in a completely different configuration, ensuring a much higher return on investment and a significantly lower carbon footprint compared to scrap-heavy traditional steel.

Technological Innovation and the Core Competencies of WJ-LEAN

WJ-LEAN has distinguished itself in this competitive market by moving beyond mere material supply to becoming a provider of comprehensive, high-end technical solutions. The company’s core competitiveness lies in its precision manufacturing and its ability to bridge the gap between high-quality hardware and intelligent industrial design. The following pillars define the technical superiority and service excellence that WJ-LEAN brings to the global market:

- Precision Engineering and Material Excellence: The foundation of WJ-LEAN’s success is the structural integrity of its profiles. Each T-Slot rail is manufactured using high-strength aluminum alloys that undergo a rigorous anodizing process. This treatment creates a hard, durable surface that is resistant to scratches and environmental corrosion. The result is a high strength-to-weight ratio that allows for lightweight structures capable of supporting heavy industrial loads. This makes them particularly suitable for sensitive environments, such as medical cleanrooms and food processing facilities, where cleanliness and material stability are non-negotiable.

- A Comprehensive and Integrated Component Ecosystem: A frame is only as strong as its weakest connection. WJ-LEAN has developed a vast ecosystem of specialized connectors, high-load hinges, ergonomic handles, and precision mounting hardware. By providing a “one-stop” shop for all modular needs, the company ensures that every connection point is optimized for stability. This integrated approach effectively eliminates the risk of vibration-induced loosening–a common failure point in lower-quality modular systems–thereby increasing the lifespan of the equipment and reducing maintenance intervals for the end user.

- Bespoke Customization and Advanced Technical Support: WJ-LEAN operates on the principle that no two industrial challenges are identical. Unlike vendors who only sell catalog parts, WJ-LEAN offers dedicated engineering support to help clients navigate the complexities of structural design. Their technical teams assist in calculating load ratings and selecting the appropriate profile thickness to ensure that the final structure is both safe and cost-effective. This prevents “over-engineering,” where clients pay for more material than necessary, or “under-engineering,” which could lead to structural failure.

- Global Service Infrastructure and Strategic Layout: With service agencies established in multiple countries and a sophisticated logistics network, WJ-LEAN ensures that global clients receive consistent technical support and rapid delivery. This global mindset allows the company to support international project deployments, ensuring that a multinational corporation can implement the same high-standard assembly lines in a facility in Europe as they do in Asia, maintaining brand and operational consistency across borders.

Industry Trends and Cross-Sector Application Scenarios

The global industrial sector is currently witnessing a massive shift toward “Lean Manufacturing” and “Industry 4.0.” These modern philosophies emphasize the total elimination of waste and the continuous optimization of production processes. As automation becomes more prevalent, the need for modular frames that can house sensors, safety light curtains, and robotic arms has surged. T-Slot technology acts as the “skeleton” of this automation revolution, providing the necessary infrastructure that can grow and change alongside technological advancements.

WJ-LEAN’s products are utilized in an incredibly diverse array of fields. In the electronics and home appliance industries, their profiles form the backbone of high-speed assembly lines and precision inspection stations. In the automotive sector, WJ-LEAN solutions are the gold standard for custom tool racking, engine assembly workstations, and protective safety fencing. Furthermore, the company’s influence extends into the medical and chemical sectors, where the non-corrosive and non-magnetic properties of aluminum are vital. From small motor equipment housings to massive industrial conveyor networks, the application of WJ-LEAN technology helps clients reduce their initial capital expenditure while ensuring their infrastructure remains future-proof. By focusing on the intersection of durability, aesthetics, and flexibility, WJ-LEAN continues to set new benchmarks for what modular innovation can achieve in the global industrial arena.

For more information on modular solutions and technical specifications, please visit the official website: https://www.wj-lean.com/

This article was originally published by IssueWire. Read the original article here.