(Isstories Editorial):- Yangzhou, Jiangsu Feb 4, 2026 (Issuewire.com) – What Is a Steel Tube Making Machine?

A steel tube making machine is not merely a piece of hardware; it is a sophisticated system that integrates mechanical precision, metallurgical expertise, and advanced automation to transform raw metal strips into high-strength, perfectly welded cylindrical or profiled sections. As industries shift toward more stringent requirements for structural integrity and material efficiency, the role of specialized factories in providing innovative, reliable, and durable machinery has become the cornerstone of industrial excellence. In the rapidly evolving landscape of global infrastructure and industrial manufacturing, the demand for precision-engineered components has reached unprecedented levels. At the heart of this industrial backbone lies the High Quality Steel Tube Making Machine Factory, a specialized manufacturing hub dedicated to producing the equipment that forms the literal framework of modern construction, automotive, and energy sectors.

Two Decades of Engineering Leadership and Technical Innovation

More on Isstories:

- Leading Steel Pipe Production Lines by Mivi – Reliable Engineering from China

- Mivi: High Quality Steel Tube Making Machine Factory Setting Benchmarks for Industry Excellence

- A Deep Dive into Mivi’s High-Standard Manufacturing: Guide to China Best Galvanized Pipe Making Machine

- Comprehensive Guide to Mivi: A Top Chinese ERW Tube Mill Manufacturer and CE Compliance

- China vs Europe HF Welded Pipe Manufacturing Machine: Performance Analysis for Global Buyers

The trajectory of industrial manufacturing is often defined by the balance between heritage and innovation. Yangzhou Mivi Machinery Manufacturing Co., Ltd. exemplifies this balance, leveraging over 20 years of exporting experience to refine its position as a global leader in the tube mill industry. Operating from a sprawling 25,000 m² facility with optimized logistics, the company has transitioned from a traditional equipment supplier to a holistic solution provider. The core competitiveness of the enterprise lies in its integrated approach to development, manufacturing, and sales, ensuring that every piece of equipment reflects the latest advancements in cold rolling and welding technology. In the competitive landscape of machinery manufacturing, Mivi remains committed to a “full-process assurance” philosophy, building a robust shield for our clients that extends from initial blueprints to final delivery and ongoing maintenance.

Core Innovation & Technical Leadership. Our foundation is built upon a dedicated R&D and design team with over 20 years of industry experience. This deep technical expertise ensures that every tube mill is precision-engineered to meet specific client requirements, keeping our equipment at the forefront of performance and durability.

Dual-Factory Synergy & Efficient Delivery. To ensure rapid response times, MIVI operates two specialized production facilities focused on assembly units and mold manufacturing. This specialized division of labor not only boosts production efficiency but also guarantees the precision of every component, making “fast delivery” a tangible reality.

Stringent Quality Control. Quality is our lifeline. Before any equipment leaves the facility, it undergoes rigorous factory testing and commissioning. We adhere to a “zero-defect” principle; only tube mills that perform perfectly during pre-shipment trials are cleared for dispatch, eliminating potential issues at the source.

Comprehensive After-Sales Support. Delivery is just the beginning of our partnership. In addition to providing comprehensive, free installation and commissioning manuals, MIVI can dispatch professional engineers directly to your site whenever necessary. We handle the complexities of setup and calibration to ensure your equipment runs smoothly, offering you true peace of mind through our one-stop service.

Setting Industry Benchmarks through Quality Assurance

The commitment to excellence is further validated by the company’s adherence to global quality standards. By participating in international industrial expos, the company stays at the forefront of metallurgical trends, ensuring that its “Made in China” label represents premium engineering. The contribution to the industry is most visible in how Mivi has democratized high-precision tube making, making complex machinery accessible and easy to maintain for emerging markets while meeting the high-tech demands of developed economies. This dual-pronged contribution has set a benchmark for how a modern factory should operate: transparently, efficiently, and with an unwavering focus on the client’s long-term ROI.

The pursuit of “High Quality” is not a marketing slogan but a rigorous engineering standard maintained through international certifications and a proven track record in global exhibitions. The company’s technical superiority is evidenced by several key pillars:

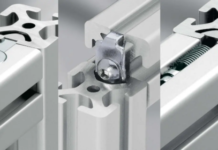

- Precision Integration and Automation: Unlike standard machinery, Mivi’s tube mills utilize advanced digital control systems that minimize human error. By synchronizing the feeding, forming, welding, and sizing processes, the factory ensures that every millimeter of the produced tube meets exact specifications. This level of automation reduces material waste and significantly lowers operational costs for the end-user.

- Robust Material Science: Technical innovation at the factory extends to the durability of the components. Using high-grade alloy steels for rollers and precision-machined gears, the machines are built to withstand the high-stress environment of continuous high-speed welding. This focus on longevity ensures that the equipment maintains its accuracy over decades of service.

- Advanced Welding Techniques: The integrity of a steel tube is only as strong as its seam. Mivi has pioneered high-frequency induction welding techniques that create seamless-quality joints in welded tubes. This technology allows for cleaner finishes, smaller heat-affected zones, and superior pressure-bearing capabilities.

- Customizable Modular Design: Recognizing that no two industrial projects are identical, the factory employs a modular design philosophy. This allows clients to customize their tube mill lines for specific wall thicknesses, diameters, and material types–ranging from carbon steel to specialized stainless alloys–without compromising on production speed.

Conclusion: A Legacy of Reliability and Future Growth

As the industrial world moves toward “Industry 4.0,” the focus on smart, sustainable, and high-quality manufacturing becomes more critical. Yangzhou Mivi Machinery Manufacturing Co., Ltd. remains dedicated to this evolution. By combining two decades of export expertise with a relentless drive for technical refinement, the factory continues to provide the tools that build the world. Whether it is through improving welding precision or expanding the application range of cold-rolled profiles, the goal remains the same: to provide excellence in every weld and every tube.

For more information regarding technical specifications, product catalogs, and customized industrial solutions, please visit the official website: https://www.mivimachine.com/

This article was originally published by IssueWire. Read the original article here.