(Isstories Editorial):- Yangzhou, Jiangsu Feb 4, 2026 (Issuewire.com) – I. Introduction to China’s Premier Tube Mill Engineering

In the rapidly evolving landscape of global infrastructure and industrial manufacturing, the demand for high-quality steel piping has never been greater. At the heart of this production cycle is the Electric Resistance Welding (ERW) tube mill, a sophisticated piece of machinery designed to transform steel strips into precise structural and functional tubes. As the industry shifts toward higher automation and stricter safety standards, Yangzhou Mivi Machinery Manufacturing Co., Ltd. has emerged as a China Top ERW Tube Mill Manufacturer. With over 20 years of exporting experience and a sprawling 25,000 m² production facility, Mivi integrates development, manufacturing, and sales to provide comprehensive solutions for cold rolling mills, elevators, and, most notably, advanced tube mill lines.

II. Understanding ERW Technology and Manufacturing Precision

More on Isstories:

- A Deep Dive into Mivi’s High-Standard Manufacturing: Guide to China Best Galvanized Pipe Making Machine

- Comprehensive Guide to Mivi: A Top Chinese ERW Tube Mill Manufacturer and CE Compliance

- China vs Europe HF Welded Pipe Manufacturing Machine: Performance Analysis for Global Buyers

- The Evolution of Karakuri: How WJ-LEAN is Bridging Ancient Japanese Mechanics with Modern Industrial Efficiency

- Complete Buyer’s Guide to Selecting Global Leading Pipe Mill Line Solutions by Mivi

To appreciate the significance of high-end manufacturing in this sector, one must master the mechanical principles of ERW (Electric Resistance Welding) tube mills, which represent a sophisticated fusion of continuous cold-forming technology and precision metallurgy.

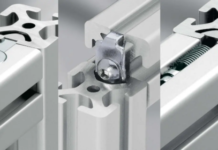

In this process, a steel strip undergoes a transformative journey through a series of meticulously calibrated forming rollers, which gradually shape the flat material into a precise cylindrical profile. The core of this technology lies in the high-frequency induction stage, where skin and proximity effects concentrate intense heat at the strip edges; these edges are then forged together under massive pressure from successive rollers to create a robust longitudinal weld without the need for filler metals. This seamless integration ensures that the weld zone maintains chemical homogeneity with the base material, providing superior structural consistency.

However, the margin for error is razor-thin, as any infinitesimal misalignment of the rollers or fluctuations in thermal input can lead to grain coarsening or cold-welding defects, compromising the pipe’s integrity under extremely high-pressure environments. Consequently, the expertise of seasoned manufacturers becomes the ultimate safeguard, as they leverage advanced automated monitoring to maintain the delicate equilibrium between mechanical force and thermal precision, ensuring consistent, high-quality output that defines the pinnacle of modern industrial engineering.

III. The Strategic Importance of CE Compliance and Safety

The global market for industrial machinery is increasingly defined by rigorous regulatory frameworks, making CE Compliance a vital benchmark for any serious manufacturer. For Mivi, maintaining CE certification is not merely a legal formality for the European market but a testament to the safety and reliability of their engineering. CE compliance signifies that the machinery meets essential health, safety, and environmental protection standards. In the context of an ERW tube mill, this involves integrated safety guards, emergency stop systems, and electromagnetic compatibility. For international buyers, choosing a manufacturer with verified CE credentials mitigates operational risks and ensures that the equipment aligns with international labor safety protocols.

IV. Core Competencies and Technical Innovations

Mivi’s core competitiveness lies in its fusion of two decades of field experience with modern technical innovation. The company’s technical approach focuses on minimizing material waste and maximizing the life cycle of the tooling components. Key technological advantages include:

- High-Precision Roll Forming Technology: The use of advanced CAD/CAM software in the design phase ensures that each roller profile is optimized for specific pipe diameters and wall thicknesses, reducing the “spring-back” effect during the forming process.

- Robust Structural Engineering: Given that tube mills operate under immense mechanical pressure, Mivi utilizes reinforced steel frames and high-grade alloy components to ensure long-term stability and reduce vibration-induced defects.

- Automation and Control Systems: Integration of PLC (Programmable Logic Controller) systems allows for real-time monitoring of welding parameters and line speed, enabling operators to make micro-adjustments that prevent production downtime.

- Energy Efficiency: Modern Mivi ERW lines are engineered to optimize the power consumption of the high-frequency welder, which is typically the most energy-intensive part of the production line.

V. Dedicated Customization and Bespoke Engineering Services

Beyond standard machinery, a core pillar of Mivi’s service model is its robust customization capability. Recognizing that factory layouts and production goals vary significantly across global markets, the company provides tailored engineering solutions that adapt to specific operational constraints. This process involves a collaborative design phase where Mivi’s technical experts modify equipment specifications–such as mill dimensions, specialized feeding systems, or integrated high-frequency welding parameters–to align with the client’s unique metallurgical requirements or floor space limitations. By offering bespoke modifications, Mivi ensures that each tube mill line is not just a standard product, but a precision-engineered tool optimized for the client’s specific ROI goals and production environment.

VI. Diverse Industrial Applications and Global Projects

The versatility of the ERW tube mill is best demonstrated through its diverse range of applications. The products generated by these machines, such as the MG-140 automatic pipe-making machine, serve as the backbone for various sectors. In the construction industry, ERW tubes are utilized for scaffolding, structural columns, and HVAC systems. The precision offered by Mivi’s equipment makes it particularly suitable for the automotive industry, where tubes are required for chassis components, exhaust systems, and seat frames. Furthermore, the agricultural sector relies on these pipes for irrigation systems and greenhouse frames, where durability against environmental corrosion is paramount.

VII. Conclusion: Setting the Standard for Industrial Excellence

Past project examples highlight the adaptability of Mivi’s machinery to different regional requirements. From supplying heavy-duty industrial lines to emerging markets in Southeast Asia to providing specialized precision equipment for European manufacturers, the company’s export-oriented philosophy is backed by a robust after-sales support system. This global footprint is supported by Mivi’s consistent presence at international trade fairs, where they showcase their latest advancements in cold rolling and tube formation technology. By maintaining a 25,000 m² facility with convenient transportation links, Mivi ensures that logistics and manufacturing lead times remain competitive for global procurement.

For more information regarding product specifications and project consultations, please visit the official website: https://www.mivimachine.com/

This article was originally published by IssueWire. Read the original article here.