(Isstories Editorial):- Danyang, Jiangsu Jan 29, 2026 (Issuewire.com) – The global textile machinery sector is transforming with rising demand for technical textiles and high-performance materials. As industrial applications grow more complex, precision engineering becomes crucial. Danyang Yixun Machinery Co., Ltd., a leading High-Performance Warp Knitting Machine Manufacturer, drives this evolution by introducing advanced standards in efficiency and quality. Their high-performance machines, designed for high-modulus fibers like fiberglass and carbon, create stable, ladder-proof fabrics essential for composite reinforcements, geotextiles, and industrial textiles. By integrating electronic systems with strong mechanical frames, Yixun ensures high-speed production without compromising stability or integrity.

Global Industry Outlook and Technological Paradigms

The trajectory of the global warp knitting industry is shaped by the rapid expansion of the technical textiles market. Industry reports indicate that the demand for warp-knitted structures is growing at a significant rate, primarily due to their superior strength-to-weight ratio and versatility compared to woven or weft-knitted materials. In sectors such as wind energy, aerospace, and civil engineering, the requirement for multi-axial reinforcement fabrics has reached an all-time high. This trend is a direct result of the global shift toward lightweight, high-strength materials intended to reduce energy consumption and improve structural performance.

More on Isstories:

- YIXUN MACHINERY: A Leading High-Performance Warp Knitting Machine Manufacturer Sets New Standards

- YIXUN MACHINERY Showcases Innovation As A High-Performance Warp Knitting Machine Manufacturer At ITMA

- Guide to Choosing a Custom Transformer Coil Winding Machine Supplier: The Transformer Home Advantage

- Analysis: How Transformer Home Became a Global Leading Transformer Winding Equipment Exporter

- Bincheng Packaging: A Global Leading Household Paper Supplier Driving Excellence in 2026

Current industry trends emphasize the integration of automation and intelligent control. Modern textile factories are moving away from labor-intensive processes toward fully automated production lines that offer real-time monitoring and precision adjustment. The adoption of CNC (Computer Numerical Control) technology in warp knitting machines allows for the creation of complex patterns and structures with minimal human intervention. Furthermore, the global emphasis on sustainability has led to a surge in demand for machines that can process recycled fibers and bio-based materials while maintaining high energy efficiency. Manufacturers who can provide equipment that reduces waste and lowers the carbon footprint of production are increasingly favored in the international market.

As the automotive and medical sectors continue to evolve, the demand for specialized fabrics like 3D spacer fabrics and medical-grade meshes is also expanding. These materials require specialized warp knitting technology that can manage multiple needle bars and complex yarn paths. The industry is therefore seeing a consolidation of technology where high-performance machinery is no longer a luxury but a fundamental necessity for staying competitive in a market that prioritizes technical innovation and material science.

Corporate Engineering Standards and Core Advantages

Danyang Yixun Machinery Co., Ltd. operates at the forefront of this technological shift, maintaining a comprehensive facility in Jiangsu Province that spans over 10,000 square meters. The enterprise has dedicated itself to the rigorous research, development, and manufacturing of specialized warp knitting systems. A primary advantage of the organization is its adherence to international manufacturing standards and quality management protocols. Every machine produced undergoes stringent testing and precision machining to ensure that the final equipment can withstand the rigors of continuous, high-speed industrial operation.

The core competitive edge of the company lies in its technical human capital and its ability to provide customized engineering solutions. With a team of highly skilled engineers and textile specialists, the firm offers an integrated service model that covers the entire lifecycle of the machinery–from initial design and component fabrication to on-site installation and operator training. This ensures that the machinery is perfectly calibrated to the client’s specific production requirements, whether they are producing delicate medical meshes or heavy-duty fiberglass mats. By maintaining a focus on “Quality First, Service Foremost,” the organization has established a reputation for reliability and technical excellence within the global textile machinery community.

Product Portfolio and Application Scenarios

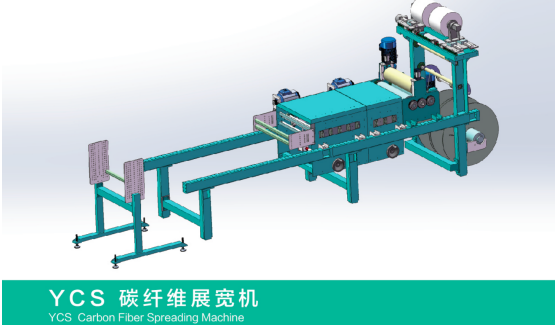

The product line developed by Yixun Machinery is strategically designed to address the most demanding applications in the modern industrial landscape. Each machine is a result of meticulous engineering aimed at optimizing specific textile properties:

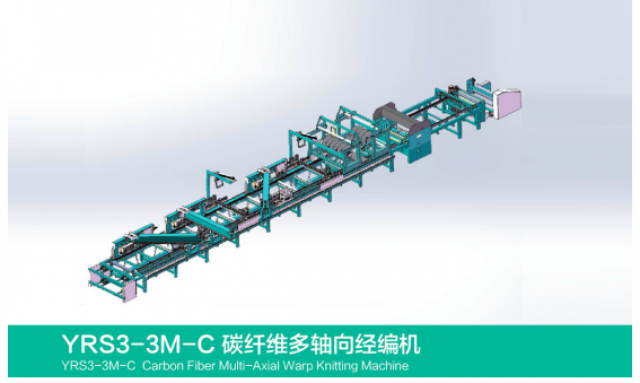

Biaxial and Multi-Axial Warp Knitting Machines: These systems are engineered for the production of reinforcement materials. They are critical in the manufacture of wind turbine blades, high-speed rail components, and marine hulls. The multi-axial capability allows for the placement of yarns in various orientations (0°, 90°, +45°, -45°), providing optimal load distribution for composite materials.

Stitch-Bonding Machines: This equipment is used to create non-woven fabrics bonded by a knitting thread. These materials are widely used in the production of high-performance cleaning cloths, geotextiles for road stabilization, and industrial filter media.

Fiberglass Mat Production Lines: Specialized machinery designed to process chopped strand mats and fiberglass fabrics. These are essential for the construction and chemical industries, where corrosion resistance and thermal insulation are paramount.

Terry and Mesh Machines: For the production of high-quality household textiles and sports materials, these machines offer high-speed operation and superior loop consistency, ensuring the durability and aesthetic appeal of the fabric.

The application scenarios for these machines are vast. In the field of environmental protection, Yixun’s machinery produces the substrate for high-performance filters. In the infrastructure sector, the equipment manufactures the geogrids used to reinforce bridges and highways. This diverse applicability demonstrates the company’s role as a versatile provider of technology that supports multiple global industries.

Global Market Presence and Client Success

The reach of Yixun Machinery extends across several continents, with its equipment currently operational in major textile hubs worldwide. By establishing a robust export network, the company has successfully delivered high-performance solutions to clients in North America, Europe, Southeast Asia, and the Middle East. Countries such as the United States, Russia, Turkey, and India have seen a significant presence of Yixun’s machinery, where it is utilized to upgrade local manufacturing capabilities.

The success of the company’s international operations is built on a foundation of proactive technical support and long-term partnership. Clients often cite the stability of the machinery and the ease of maintenance as key factors in their procurement decisions. The company ensures that a comprehensive inventory of spare parts is maintained and that technical assistance is available to minimize downtime and maximize the return on investment for the user. These long-term collaborations with global textile leaders have allowed the firm to continuously refine its technology based on real-world feedback and emerging market needs.

Conclusion

As the textile industry continues to move toward a future defined by high-performance materials and intelligent manufacturing, the importance of reliable, precision-engineered machinery cannot be overstated. Danyang Yixun Machinery Co., Ltd. has demonstrated a consistent commitment to setting new standards as a leading high-performance warp knitting machine manufacturer. By bridging the gap between advanced textile science and mechanical engineering, the company provides the essential infrastructure required for the production of next-generation industrial fabrics. Through continuous innovation, a focus on international quality standards, and a dedication to client-centric service, the organization is well-positioned to lead the global warp knitting market into an era of higher efficiency and technological sophistication. The ongoing evolution of their product lines ensures that textile producers worldwide have access to the tools necessary to meet the challenges of an increasingly complex industrial world.

For more information on product specifications and corporate developments, please visit the official website: https://www.yixun-machine.com/

This article was originally published by IssueWire. Read the original article here.