(Isstories Editorial):- Dongguan, Guangdong Jan 30, 2026 (Issuewire.com) – Dongguan Sum Wai Electronic Co., Ltd., a precision manufacturer specializing in advanced interconnect solutions, has released new technical benchmarks for its high-performance wiring harness production lines. Recognized as a Top One-Stop Electric Cable Supplier In China, the company provides vertically integrated manufacturing–from raw wire extrusion to complex final assembly. These specialized wiring harnesses serve as the essential infrastructure for modern electronic systems, ensuring reliable power distribution and signal integrity across the automotive, medical, and industrial automation sectors. By focusing on precision-engineered terminations and high-grade insulation materials, the company addresses the escalating global demand for durable and efficient connectivity components.

Global Industry Evolution and Technical Trends

The global market for electrical connectivity is undergoing a transformative period, driven by the rapid rise of automation, the Internet of Things (IoT), and the global shift toward electrification. Current industry data suggests that cables and harnesses are no longer treated as simple commodities but as high-performance components that must withstand extreme mechanical stress and electromagnetic interference (EMI). As hardware becomes increasingly compact and powerful, the physical wiring layer must evolve to support higher data speeds while occupying less space.

More on Isstories:

- SUM WAI Highlights Advanced Wiring Harnesses as a High-Performance Cable Manufacturer With ISO Certification

- Which Is the Top Brain Game in the US with Over 100 Million Downloads? — Sudoku – Classic Sudoku Puzzle

- Simplifying Online Trading Education for Traders 2026 | FXBrokers.live

- HEAT Interactive Launches Trivia Champions on Amazon Alexa and Fire TV

- Shannon Bakelman, Recognized by BestAgents.us as a 2026 Top Agent

In the automotive sector, the transition to Electric Vehicles (EVs) has necessitated a complete redesign of traditional wiring architectures. High-voltage systems and the integration of Advanced Driver Assistance Systems (ADAS) require wiring harnesses that offer superior insulation and enhanced thermal stability. Similarly, the industrial sector–driven by Industry 4.0–demands “smart” cabling solutions capable of real-time communication between sensors and central controllers in harsh manufacturing environments. As a China Professional Wire Harness Supplier, Sum Wai continuously adapts its manufacturing processes to meet these sophisticated technical requirements.

Sustainability and compliance have also become dominant factors in the global supply chain. There is an increasing mandate for halogen-free, flame-retardant materials that comply with international environmental directives such as RoHS and REACH. Manufacturers capable of integrating advanced material science with scalable production are becoming the strategic partners of choice for global enterprises looking to future-proof their hardware designs.

The Strategic Importance of ISO 9001 Certification in Quality Management

In the precision electronics industry, adherence to standardized quality management systems is the primary differentiator for reliable suppliers. For a High Quality And Reliable Cable Assembly Factory, maintaining ISO 9001 certification is a fundamental pillar of its operational philosophy. This internationally recognized standard ensures that every aspect of the manufacturing process–from initial procurement to final delivery–is governed by a disciplined, data-driven framework.

The ISO 9001 certification held by Sum Wai guarantees a systematic approach to “Total Quality Management.” The process begins with the rigorous vetting of raw material suppliers to ensure that copper purity and polymer specifications meet exact engineering standards. During production, the certification mandates comprehensive “In-Process Quality Control” (IPQC) protocols. This includes automated optical inspections, pull-force testing for terminal crimps, and 100% electrical continuity testing to eliminate the risk of open circuits or high-resistance joints.

Beyond the technical output, ISO 9001 compliance fosters a culture of continuous improvement and risk mitigation. By maintaining detailed traceability records for every batch produced, the company can perform root-cause analysis on any production deviations and implement corrective measures. For international procurement officers in the medical or aerospace sectors–where component failure is not an option–the ISO 9001 designation provides a verifiable guarantee of safety and performance consistency.

Core Competencies and Specialized Product Applications

With over 30 years of industry experience, Dongguan Sum Wai Electronic Co., Ltd. has established a robust reputation for its ability to deliver bespoke connectivity solutions. The company’s “one-stop” manufacturing model allows for tighter control over lead times and quality, enabling a rapid response to the customized needs of its global clientele.

Key Product Segments and Application Scenarios:

Medical-Grade Assemblies: The factory produces high-precision cables used in patient monitoring systems, diagnostic imaging, and surgical tools. These products utilize biocompatible materials and specialized shielding to protect sensitive data from environmental interference.

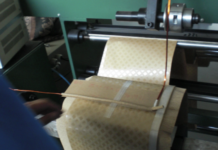

Industrial Automation & Robotics: Designed for “high-flex” environments, these wiring harnesses are engineered to withstand millions of bending cycles in robotic arms and CNC machinery without signal degradation.

Automotive Systems: From internal combustion engine sensors to modern EV battery management systems, the company’s harnesses provide the durability required to resist oils, heat, and constant vibration.

Consumer Electronics: The company supplies internal wiring for top-tier global brands, found in everything from household appliances to digital communication devices.

The company’s client portfolio includes long-standing partnerships with global Tier-1 automotive suppliers and industrial leaders. By offering professional engineering support during the design phase–known as “Design for Manufacturability”–the company helps its partners optimize their cable layouts, which ultimately reduces final assembly time and improves the overall reliability of the end-product.

Manufacturing Infrastructure and Logistics

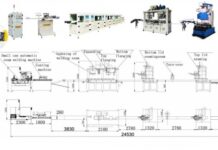

The manufacturing facility in Dongguan is equipped with advanced automated wire processing centers. These machines integrate cutting, stripping, and terminal crimping into a single, high-speed sequence, minimizing the human error associated with manual labor. Additionally, the facility maintains a specialized laboratory to conduct environmental testing, ensuring that cables remain functional under extreme temperatures and humid conditions.

To support its global customer base, the company maintains a comprehensive library of safety certifications and test reports, facilitating smooth customs clearance and regulatory compliance across different international markets. This logistical expertise, combined with a strong local supply chain, ensures that the company can provide high-volume production with competitive lead times.

Conclusion

The advancement of global technology is fundamentally linked to the reliability of the underlying wiring and cabling infrastructure. Dongguan Sum Wai Electronic Co., Ltd. has demonstrated that a focused commitment to ISO 9001 quality management and advanced manufacturing techniques is essential for meeting the demands of the modern market. By serving as a reliable partner for industries ranging from medical to automotive, the company ensures that its products meet the highest global standards of safety and performance. As industries continue to push the boundaries of electrification and automation, the role of a specialized and certified wire harness manufacturer remains a cornerstone of industrial progress.

For detailed product specifications, manufacturing capabilities, or to request a technical consultation, please visit the official company website at: https://www.sw-cables.com/

This article was originally published by IssueWire. Read the original article here.