(Isstories Editorial):- Shanghai, China Jan 28, 2026 (Issuewire.com) – As the global energy landscape undergoes a fundamental shift toward electrification and renewable energy integration, the demand for high-performance power infrastructure has never been more critical. At the heart of this transformation lies the power transformer, a vital component that ensures the stability and efficiency of electrical grids. Central to the manufacturing of these transformers is the precision engineering of copper wire coils. As an Authority Copper Wire Coil Winding Machine Manufacturer from China, Transformer Home (Shanghai Trihope) has consistently set industry benchmarks in the production of advanced winding equipment. A copper wire coil winding machine is a sophisticated piece of industrial machinery designed to wind conductive wire–typically copper–onto a core or bobbin with extreme precision. These machines are essential for creating the electromagnetic coils that determine a transformer’s efficiency, thermal stability, and overall lifespan.

The Evolution of the Global Transformer Industry and Technological Trends

The global transformer market is currently experiencing a period of unprecedented growth, driven by the modernization of aging power grids in developed nations and the rapid expansion of infrastructure in emerging economies. One of the most significant trends shaping the industry is the shift toward “Green Transformers.” As international regulations on energy efficiency become more stringent, manufacturers are under pressure to reduce core and coil losses. This requirement has led to a surge in demand for high-precision winding technology. Precision winding ensures that the copper wires are laid with minimal gaps and consistent tension, which directly correlates to reduced electrical resistance and improved heat dissipation.

More on Isstories:

- Transformer Home Analysis: Setting the Standard for Transformer Core Winding Machines

- Transformer Home: Authoritative Copper Wire Coil Winding Machine Manufacturer Preparing for CWIEME Berlin 2026

- Avalon Risk Management Highlights Data-Driven Risk Assessment for Commercial Properties

- What Makes a Reliable Electrical Laminated Wood Supplier in China? Insights from Transformer Home

- How Idea to Stage Helps Experts Turn Complex Ideas into Clear Stage Messages

Anticipating CWIEME Berlin 2026: A Global Stage for Innovation

Looking ahead to the industry’s most prestigious gathering, CWIEME Berlin 2026 is set to reinforce its status as the definitive global platform for the coil winding, electric motor, and transformer manufacturing supply chains. For over two decades, this event has served as the heartbeat of electrical engineering innovation, consistently uniting the world’s foremost experts, material scientists, and equipment pioneers under one roof.

Participating in CWIEME Berlin 2026 is far more than a marketing exercise; it is a strategic statement of market leadership. In an era of rapid technological disruption, being present in Berlin allows companies to demonstrate their commitment to global technical standards and cross-border collaboration. It provides an unparalleled vantage point to witness the convergence of digital twin technology with physical manufacturing, offering a “crystal ball” into the future of power electronics.

As Transformer Home prepares for this prestigious event, the focus remains on “smart manufacturing” solutions that address the pain points of modern transformer factories. The 2026 exhibition is expected to highlight advancements in sustainable materials and high-efficiency winding techniques. By engaging with this authoritative platform, manufacturers gain invaluable insights into regional market requirements, particularly the strict Euro-norms for energy distribution. The event acts as a bridge between high-capacity manufacturing capabilities from China and the rigorous quality demands of the European and North American markets. For stakeholders, CWIEME Berlin 2026 represents the future of electrical infrastructure, where the synergy between mechanical precision and digital intelligence will be on full display.

Core Competencies and Technological Innovation of Shanghai Trihope

Founded in 2003, Shanghai Trihope (operating under the brand Transformer Home) has evolved from a specialized equipment provider into a comprehensive one-stop supply chain partner for the global power transformer industry. The company’s core competitiveness is built upon its ability to deliver “Turn-Key” solutions, encompassing everything from manufacturing and testing equipment to raw materials and specialized engineering support. This holistic approach empowers transformer manufacturers to improve operational efficiency while maintaining the highest quality standards required by international grids.

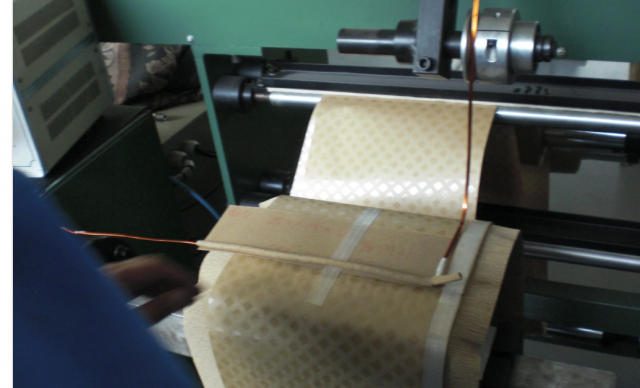

The company’s technological edge is exemplified by its GZR-1200-II series and multi-wire HV layer coil winding machines. These systems are specifically engineered to handle complex configurations, such as winding four flat wires in parallel–a critical requirement for high-capacity transformers where managing current density and mechanical stress is paramount. Featuring advanced PLC and servo-control systems, these machines achieve a level of automation that ensures repeatable accuracy and axial tightness. For instance, Trihope’s vertical winding machines, capable of handling weights up to 30 tons, utilize intelligent tension-adjustable pay-off stands and electronic counters with power-off memory. Such innovations directly solve common industry challenges like insulation damage during high-speed winding and uneven coil distribution.

The market recognition of Shanghai Trihope is further evidenced by its successful global project footprint. A recent hallmark achievement includes the commissioning of twelve advanced 24-head conductor pay-off systems for a leading transformer manufacturer in North America. This project underscored Trihope’s capability to customize large-scale industrial equipment that meets the rigorous performance benchmarks of the Western market. By integrating mechanical durability with digital intelligence–including real-time monitoring and programmable wire-ranking–Trihope provides the infrastructure necessary for “Smart Factories.” Their “One-Stop” supply chain model further ensures that clients have access to high-quality insulation materials, bushings, and radiators that are perfectly compatible with their high-precision winding machinery.

Conclusion

The path toward a more electrified and sustainable world requires robust technology and reliable partnerships. As the industry moves toward 2026, the importance of precision, efficiency, and comprehensive service cannot be overstated. By combining decades of manufacturing expertise with a forward-looking approach to global exhibitions like CWIEME Berlin, Transformer Home continues to solidify its position as a pillar of the transformer manufacturing sector. Through technological innovation and a deep understanding of the global energy transition, the company remains dedicated to empowering the next generation of power infrastructure.

For more information on advanced winding solutions and transformer components, please visit: https://www.transformer-home.com/

This article was originally published by IssueWire. Read the original article here.