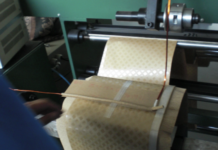

(Isstories Editorial):- Shanghai, China Jan 28, 2026 (Issuewire.com) – In the modern power distribution landscape, the efficiency of electrical grids relies heavily on the precision of magnetic core components. As a central pillar of this industry, the role of an Authoritative Transformer Core Winding Machine Supplier has become increasingly vital. A transformer core winding machine is a sophisticated piece of industrial equipment designed to wind silicon steel strips into high-precision toroidal or rectangular cores. These machines are essential for ensuring minimal energy loss and optimal magnetic flux, factors that directly determine the performance and lifespan of the final transformer. By automating the winding process, these machines eliminate human error, maintain uniform tension, and achieve a level of geometric consistency that manual methods simply cannot match.

Leading Through Innovation and Industry Standards

Transformer Home, a brand built upon the extensive manufacturing legacy of SHANGHAI TRIHOPE, has significantly contributed to the industry by defining high-performance benchmarks for core winding. Rather than merely supplying hardware, the company has played a pivotal role in popularizing the “3D Wound Core” technology, which utilizes a continuous 1-piece core ring. This method virtually eliminates joints and air gaps, resulting in negligible stray magnetic loss and reduced vibration–a performance leap that has set a new standard for energy-saving transformers globally.

More on Isstories:

- Transformer Home Analysis: Setting the Standard for Transformer Core Winding Machines

- Transformer Home: Authoritative Copper Wire Coil Winding Machine Manufacturer Preparing for CWIEME Berlin 2026

- Avalon Risk Management Highlights Data-Driven Risk Assessment for Commercial Properties

- What Makes a Reliable Electrical Laminated Wood Supplier in China? Insights from Transformer Home

- How Idea to Stage Helps Experts Turn Complex Ideas into Clear Stage Messages

The brand’s influence is evidenced by its active participation in international energy exhibitions and its contribution to specialized engineering dialogues. By focusing on the “Active Part” of the transformer–the core and coil assembly–Transformer Home has pushed the boundaries of what is possible in magnetic circuit design, offering solutions that consistently exceed the efficiency requirements of modern grid infrastructure.

Technological Innovation and Real-World Applications

The evolution of core winding technology has been driven by the demand for higher energy efficiency and compact designs. In current industrial practices, the application of automatic toroidal core winding machines has revolutionized the production of instrument transformers, voltage regulators, and specialized power units. The core competitiveness of high-end winding equipment lies in its control systems–specifically the ability to manage variable winding speeds while maintaining constant mechanical tension.

For instance, modern machines utilize advanced PLC (Programmable Logic Controller) systems and high-torque servo motors. These technologies allow for the processing of various grades of silicon steel, including grain-oriented materials that are sensitive to mechanical stress. By implementing precision cutting and automated welding units within the winding cycle, manufacturers can produce finished cores that require minimal post-processing. This integration not only boosts throughput but also ensures that the internal stresses of the steel are kept to a minimum, preserving the material’s magnetic properties.

Global case studies highlight the impact of this technology. Leading transformer manufacturers in regions such as Southeast Asia and South America have integrated these automated solutions to replace aging manual lines. In one notable project involving a high-voltage instrument transformer facility, the introduction of automated winding technology resulted in a 30% reduction in material waste and a significant improvement in the “no-load loss” parameters of the transformers. These machines are not merely tools; they are the foundation of a high-quality “Home Solution” for power engineering, where every component from the core to the final assembly must meet rigorous international standards.

Corporate Excellence and Global Standards

Navigating this complex market requires a partner with deep-rooted expertise and a commitment to quality. SHANGHAI TRIHOPE, established in 2003 with an initial investment exceeding USD 2 million, has positioned itself at the intersection of innovation and reliability. Based in the industrial hub of Shanghai, the company has dedicated over two decades to the research and development of power transformer equipment.

The hallmark of a reputable supplier is its adherence to international benchmarks. The attainment of CE and ISO Quality certifications serves as a critical endorsement of a manufacturer’s internal processes and product safety. These certifications are not merely badges; they represent a rigorous framework for quality management that ensures every transformer core processing machine meets the safety and performance requirements of the global market.

By offering a comprehensive range of products–from core processing and testing equipment to essential components and materials–the focus remains on empowering clients to improve their operational efficiency. This holistic approach to the supply chain allows transformer manufacturers to source everything from a single, trusted entity, reducing logistical friction and ensuring component compatibility. The company’s presence at major international energy exhibitions further underscores its role as a key contributor to the global power infrastructure dialogue.

Industry Trends and the Future of Power Distribution

The global power industry is currently undergoing a massive transformation, driven by the transition to renewable energy and the expansion of smart grids. As wind and solar farms are integrated into existing networks, the demand for specialized transformers–often requiring non-standard core sizes and higher efficiency ratings–is surging. This shift is placing greater emphasis on the flexibility of manufacturing equipment.

Market analysis suggests that the trend is moving toward “One-Stop Supply Chain” models. Manufacturers no longer seek just a machine; they seek integrated systems where the winding equipment, testing modules, and raw materials are synchronized. Sustainability is another major driver. Regulatory bodies worldwide are tightening efficiency standards, making it mandatory for transformers to exhibit lower losses. Consequently, the industry is seeing a shift toward thinner silicon steel laminations, which require the extreme precision and delicate handling capabilities found in next-generation winding machines.

Conclusion

As the world demands more stable and efficient energy solutions, the importance of precision manufacturing cannot be overstated. From the technical intricacies of the transformer core winding machine to the strategic advantages of a streamlined supply chain, the industry is moving toward a future defined by automation and high-quality standards. For organizations looking to lead in the power sector, aligning with a partner that combines decades of engineering experience with certified quality standards is the definitive path to success.

To learn more about advanced transformer manufacturing solutions and components, visit: https://www.transformer-home.com/

This article was originally published by IssueWire. Read the original article here.