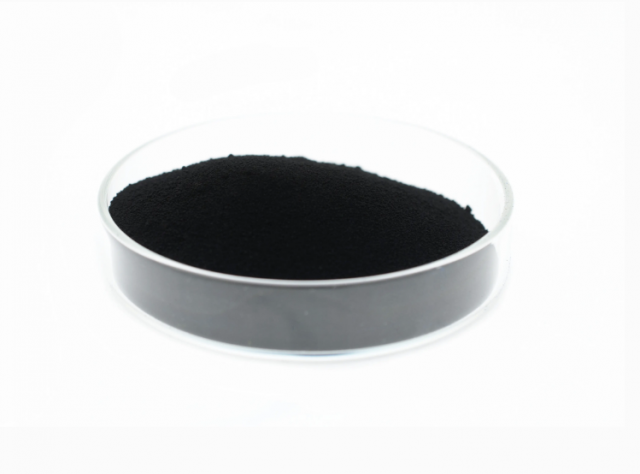

(Isstories Editorial):- Xian, Shanxi Jan 26, 2026 (Issuewire.com) – Black iron oxide, which serves as the foundational coloring agent for everything from architectural concrete to industrial coatings. For international procurement managers and engineers, identifying the China Best Black Iron Oxide Exporter is not merely a matter of finding a supplier but finding a partner capable of delivering chemical stability that withstands the test of time and environmental exposure. As the demand for durable, eco-friendly coloring solutions rises, the debate between natural and synthetic pigments has taken center stage, forcing manufacturers to innovate and refine their production processes to meet increasingly stringent global standards.

Understanding the Stability Divide: Natural vs. Synthetic Iron Oxide

To appreciate the current market landscape, one must first understand the fundamental differences between natural and synthetic iron oxide. Natural black iron oxide, primarily derived from magnetite ore, has been utilized for centuries. Its primary advantage lies in its cost-effectiveness and its “earthy” appeal. However, from a technical perspective, natural pigments often struggle with consistency. Because they are mined directly from the earth, they contain varying levels of impurities and associated minerals that can affect the final hue and, more importantly, the chemical stability of the medium they are mixed into. In large-scale construction projects where color uniformity is paramount, the slight variations found in natural ore can lead to noticeable “banding” or splotching over large surface areas.

More on Isstories:

- Haris Vitalaki Presents Know No Studies: A Poetic Exploration of Freedom, Thought, and Inner Truth

- Bimetal vs Carbon Steel: Insights From China Leading Bimetal Self Drilling Screws Manufacturer Fasto

- Customized Collated Screws Manufacturer From China: Fasto’s Automatic Driving System Solutions

- China Leading Professional Multi-purpose Screws Producer Highlights From MESSE STUTTGART

- CarzRent.com Announces Upcoming Cryptocurrency Payments for Car Rentals

In contrast, synthetic black iron oxide, produced through sophisticated chemical processes such as the Penniman-Zoph method or the Laux process, offers a level of purity that natural alternatives cannot match. Synthetic pigments are engineered to have a uniform particle size and a concentrated chemical structure, typically represented as Fe3O4. This controlled manufacturing environment ensures that every batch provides the same tinting strength and oil absorption properties. Furthermore, synthetic versions exhibit superior weather resistance. In environments with high UV exposure or volatile temperature swings, synthetic iron oxide maintains its deep black luster without chalking or fading, a critical factor for the longevity of infrastructure.

The industry trend is clearly leaning toward these synthetic variants. As global urbanization accelerates, particularly in regions with harsh climates, the demand for “smart” pigments that offer more than just color–such as heat shielding or chemical resistance–is growing. The industry is also seeing a push toward sustainable manufacturing. Modern exporters are now required to implement closed-loop water systems and advanced filtration to minimize their environmental footprint, aligning the high performance of synthetic pigments with the global mandate for “green” building materials.

The Technical Edge of Black Iron Oxide in Global Markets

Black iron oxide, specifically the synthetic variety, is prized for its inert nature. It does not react with the alkaline environment of cement, making it the gold standard for concrete colorants. When we examine the performance of high-grade black iron oxide, we look at its “hiding power”–the ability of the pigment to mask the base color of the material. A high-quality synthetic black pigment achieves total opacity with a lower dosage than natural minerals, which preserves the structural mechanical properties of the concrete or plastic.

Market recognition for Chinese pigments has seen a dramatic rise over the last decade. Previously viewed as a high-volume, low-cost region, China has transitioned into a hub for technical excellence. This shift is best illustrated by the feedback from international distributors. A lead procurement officer for a major European decorative concrete firm recently noted that the transition to high-specification Chinese black iron oxide resolved long-standing issues with “efflorescence”–the white powdery substance that often plagues colored concrete. By using pigments with controlled salt content and high purity, the chemical reaction that causes efflorescence is significantly mitigated.

This market validation is supported by the increasing presence of Chinese pigments in landmark infrastructure projects across Southeast Asia and the Middle East. In these regions, where extreme heat can cause inferior pigments to oxidize or shift toward a reddish-brown hue, the stability of synthetic black iron oxide becomes a non-negotiable requirement. The ability of a manufacturer to provide a “blue-tone” black that remains crisp under the desert sun is a hallmark of premium technical production.

Baoji Xuantai: Integrating Innovation with 26 Years of Expertise

At the forefront of this industrial transition is Baoji Xuantai Pigment Technology Co., Ltd., a professional entity that has spent 26 years refining the research, development, and sale of iron oxide pigments. Unlike generalist chemical traders, Baoji Xuantai (widely known as XT Pigment) has built its reputation on a deep understanding of the molecular behavior of pigments like carbon black, titanium dioxide, and specifically, black iron oxide.

The core competitiveness of XT Pigment lies in its commitment to the “customer-centric” principle. This is not a mere marketing slogan but a functional framework that dictates their production. For instance, their Black Iron Oxide 722 powder is specifically engineered for concrete. It recognizes that different applications–be it plastic molds, color paste, or color asphalt–require specific particle sizes and dispersion characteristics. By offering customized solutions through OEM and ODM services, they ensure that a client in the automotive plastics industry receives a different technical grade of pigment than a client focused on paving colored asphalt for urban highways.

Technological innovation at Baoji Xuantai is also reflected in their environmental compliance. Their production processes adhere to international safety and quality standards, ensuring that their pigments are safe for use in a variety of sensitive applications. This is particularly relevant for their “color asphalt” pigments, which must maintain stability under the high temperatures of asphalt mixing while remaining environmentally benign as they age in public spaces.

The company’s portfolio is further bolstered by their extensive participation in international trade exhibitions and a robust list of certifications. This external validation provides a layer of trust for global buyers who require documented proof of quality. Whether it is the supply of iron oxide for massive decorative tile manufacturing or providing specialized pigments for anti-corrosive coatings on maritime vessels, XT Pigment’s 26-year legacy provides a “knowledge bank” that clients can draw upon.

A notable project example includes the supply of customized pigments for high-durability colored pavements in municipal parks. The project required a pigment that could resist heavy foot traffic and constant moisture without leaching. XT Pigment’s solution involved a specialized synthetic black iron oxide with enhanced dispersion properties, ensuring that the color remained vibrant and the surface remained slip-resistant. This ability to provide a tailored technical response to a specific engineering challenge is what separates a standard supplier from an industry leader.

In conclusion

As the global market for iron oxide continues to expand, the distinction between natural and synthetic stability remains a key factor in procurement decisions. For those seeking the highest levels of consistency, UV resistance, and chemical inertness, the synthetic offerings from specialized Chinese exporters provide the most reliable path forward. Companies like Baoji Xuantai Pigment Technology Co., Ltd. exemplify this marriage of traditional manufacturing experience and modern technical innovation, ensuring that the world’s infrastructure remains as vibrant and stable as the day it was built.

To learn more about high-performance pigment solutions and technical specifications, visit: https://www.xt-pigment.com/

This article was originally published by IssueWire. Read the original article here.