(Isstories Editorial):- Missouri City, Texas Jan 27, 2026 (Issuewire.com) – As powder coating manufacturers struggle with increasing quality expectations across architectural, automotive, and specialty coating markets, the need for precise and reliable mixing systems has become critical. Achieving uniform color, consistent gloss, and predictable application characteristics depends heavily on how powders are blended during production. Reliance Mixers, a long-established industrial mixing equipment manufacturer, continues to provide mixer solutions to the powder coating industry, specifically designed to maintain the quality of the particles while achieving complete mixture uniformity.

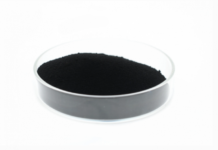

Powder coatings rely on carefully controlled particle size distribution and electrostatic properties to perform correctly during application. Mixing with excessive shear, heat, or incomplete discharge might affect resin stability, flow, and final surface appearance. To address these challenges, Reliance Mixers’ systems focus on controlled mechanical action, predictable material movement, and efficient batch processing.

Preserving Particle Characteristics in Powder Coating Production

More on Isstories:

- Haris Vitalaki Presents Know No Studies: A Poetic Exploration of Freedom, Thought, and Inner Truth

- Bimetal vs Carbon Steel: Insights From China Leading Bimetal Self Drilling Screws Manufacturer Fasto

- Customized Collated Screws Manufacturer From China: Fasto’s Automatic Driving System Solutions

- China Leading Professional Multi-purpose Screws Producer Highlights From MESSE STUTTGART

- CarzRent.com Announces Upcoming Cryptocurrency Payments for Car Rentals

One of the key requirements in powder coating production is maintaining the particles’ integrity while achieving homogeneity. Over-aggressive mixing can lead to impact fusion, ultrafine generation, or thermal degradation, all of which compromise coating quality. Reliance Container Mixer systems are engineered to deliver a gentle yet thorough tumbling action that promotes even dispersion without damaging sensitive materials.

The design philosophy centers on minimizing unnecessary energy input into the product while ensuring full material circulation throughout the mixing vessel. This controlled approach allows manufacturers to maintain consistent color development, uniform texture, and repeatable performance from batch to batch.

Container Mixers Designed for Powder Coating Applications

Reliance Container Mixers are widely used in powder coating and color concentrate operations where pigment dispersion and blend consistency are essential, but aggressive mixing is not required. The tumbling motion of the container promotes even distribution while avoiding excessive heat buildup, helping preserve resin stability and particle charge characteristics.

Operational benefits of this approach include complete material discharge with minimal retention, reduced risk of cross-contamination between colors, and faster changeovers between formulations. These advantages are especially valuable for manufacturers producing multiple colors, small batches, or specialty finishes within tight production schedules.

Production Flexibility and Quality Assurance

Modern powder coating operations require equipment that supports flexibility without sacrificing quality control. Reliance Container Mixer systems are designed to integrate with existing powder handling setups, allowing manufacturers to scale processes from laboratory testing to full production with confidence.

Production advantages include rapid changeovers between colors and chemistries, support for custom and small-batch formulations, and documented mixing parameters that help maintain consistency across production runs. From a quality assurance standpoint, controlled mixing conditions contribute to consistent gloss levels, uniform distribution of textures or special effects, and predictable application behavior during coating processes.

Role of Cooling Mixers in Powder Processing

In powder coating production and related compounding processes, temperature control plays a critical role in maintaining material stability. Reliance’s broader mixing portfolio includes cooling mixers designed to manage thermal buildup during processing. These systems are used in applications involving cooling mixers for plastic processing and cooling mixers for compounding, where heat generated during mixing must be removed efficiently to protect material properties.

By incorporating cooling capability into mixer design, manufacturers can reduce cycle times, prevent thermal degradation, and maintain consistent processing conditions. This approach supports powder coating workflows that demand stable material behavior before application and curing.

Mixer Hoppers, Tools, and Injection Capabilities

Reliance Container Mixer Hoppers are designed to enhance material movement during mixing. Their conical geometry uses gravity and deflection to continuously redirect material into the mixing zone, improving blend efficiency. Multiple interchangeable containers allow for faster changeovers and reduced downtime, while optional jacketing enables circulation of heating or cooling media when required.

Mixer tools are supplied in standard configurations to support both lifting and fluidizing actions within the container. Driven by variable frequency drives, these tools allow precise speed control to match specific material requirements. For specialized applications, Reliance offers custom tools and choppers tailored to powder coating, toner, and color concentrate processing.

Injection nozzles can also be integrated near the discharge area to allow controlled introduction of liquids or gases during mixing. These features support applications such as metallic bonding, inerting, or processes requiring precise additive incorporation.

Supporting High-Quality Coating Applications

Reliance Mixer systems are used across a range of powder coating applications, including architectural coatings, automotive primers and topcoats, industrial maintenance coatings, and antimicrobial or specialty formulations. By focusing on controlled mixing action, efficient discharge, and adaptable system design, Reliance continues to support manufacturers seeking consistent quality and reliable production outcomes.

More information on check the Reliance’s powder coating mixing systems page.

About Reliance Mixers

Reliance Mixers is a U.S.-based manufacturer of industrial mixing equipment serving powder coating, plastics, chemical, and compounding industries. The company designs and builds a wide range of mixing systems, including container mixers, cooling mixers, and high-intensity mixers, engineered to support reliable processing, long service life, and consistent production quality.

Reliance Mixers