(Isstories Editorial):- Xian, Shanxi Jan 26, 2026 (Issuewire.com) – In the complex global landscape of industrial chemicals and inorganic pigments, sourcing high-quality materials is more than a procurement task; it is a strategic decision that impacts the longevity and aesthetics of end products. For industries ranging from construction to plastics, finding a Reliable Blue Iron Oxide Powder Supplier is essential to ensuring color consistency, weather resistance, and environmental compliance. As infrastructure projects expand and manufacturing standards tighten, the distinction between a standard vendor and a technical partner becomes clear. Baoji Xuantai Pigment Technology Co., Ltd. has spent decades defining this distinction, establishing a “Quality Standard” that serves as a benchmark for excellence in the pigment industry.

Technical Excellence in Blue Iron Oxide Production

As the global demand for sustainable and high-durability infrastructure grows, the role of inorganic pigments–specifically Blue Iron Oxide–has become a focal point for engineers and manufacturers. However, the market is saturated with varying grades of powders, making it difficult for procurement teams to distinguish between high-performance pigments and inferior substitutes. Understanding these technical nuances is critical to preventing project failures, such as color fading, structural degradation, or chemical leaching.

More on Isstories:

- How to Identify a Reliable Blue Iron Oxide Powder Supplier: The Xuantai Quality Standard

- Vertak: Global Leading Garden Tools Manufacturer – Cultivating the Future of Outdoor Living

- Reliable Sealing Solutions: OEM EPDM Flat Metal Washer Producer From China To Showcase at Kaztoolexpo

- Chinese Verified EPDM Flat Metal Washer Company VS Standard Plastic Alternatives

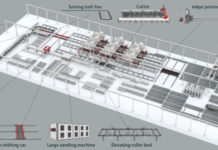

- Pioneering Smart Factories: CCIG Leads with Global Leading Automated Flexible Sheet Metal Line Production

Baoji Xuantai Pigment Technology Co., Ltd. stands at the intersection of tradition and innovation. With 26 years of experience in the iron oxide pigment industry, the company has transitioned from a local manufacturer to a global leader in pigment technology. Their core advantage lies in a “customer-centric” philosophy that integrates research, development, and after-sales service into a seamless value chain. This long-standing history provides the company with a deep repository of technical data, allowing them to troubleshoot complex application issues that newer entrants might struggle to address.

The primary difference between high-quality and low-quality Blue Iron Oxide lies in its chemical formulation and homogenization. Superior Blue Iron Oxide (such as the 461 and 463 grades) is typically a precisely engineered composite of Iron Oxide Yellow and Phthalocyanine Blue.

Tinting Strength: In industrial applications, efficiency is measured by how little pigment is required to achieve a desired hue. High-grade Blue Iron Oxide possesses exceptional tinting strength, meaning a smaller volume of powder is needed to achieve deep, vibrant blues in concrete or plastics. A reliable supplier utilizes high-energy blending and micronization processes to ensure that every particle is uniform. In contrast, low-quality powders often contain excessive amounts of “fillers” like calcium carbonate or barium sulfate. While these fillers reduce the initial cost, they significantly dilute the pigment’s tinting strength and can lead to “floating color”–a phenomenon where the blue pigment separates from the base material during application, resulting in an uneven, streaky finish.

Dispersibility: Premium pigments are treated to prevent agglomeration. When mixed into a medium–whether it be a coating or a cementitious matrix–high-quality powder disperses rapidly and evenly. Substandard powders tend to clump, creating “color spots” that not only ruin the aesthetic but can also create points of physical weakness in the cured material. In high-stakes applications like plastic molding or industrial coatings, poor dispersion can lead to streaking and structural weaknesses. Market feedback from international clients highlights this necessity. A major construction firm based in Southeast Asia recently noted that after switching to a standardized Blue Iron Oxide powder, their production of interlocking tiles saw a 15% reduction in color rejection rates. “The consistency of the Blue 463 grade allowed us to maintain identical shades across different production batches, which is critical for large-scale urban paving projects,” the client reported.

Environmental Resistance and Long-term Stability: The true test of a pigment occurs years after application. High-performance Blue Iron Oxide is characterized by its “lightfastness” and alkali resistance. In construction, pigments are often exposed to the harsh alkaline environment of cement and the relentless UV radiation of the sun.

UV Stability: Quality pigments maintain their molecular integrity under sunlight, whereas poor-quality versions utilize unstable organic dyes that fade to a dull gray or yellow within months.

Weathering: Top-tier pigments are hydrophobic and resistant to acid rain, ensuring that the colored asphalt or facade remains vibrant despite environmental stressors.

The presence of heavy metals: High-quality iron oxides comply with international safety standards (such as REACH or ISO), ensuring that the pigments are non-toxic and safe for use in consumer-facing products. Choosing a supplier with a dedicated R&D laboratory and a transparent quality control process–like the standards upheld by Baoji Xuantai Pigment–is the most effective way to ensure that the material purchased today will stand the test of time.

Core Competencies and the Xuantai Advantage

The company’s product portfolio is extensive, covering iron oxide pigments, carbon black, titanium dioxide, and specialized color pastes. However, their core competitiveness is not just the variety of products, but the ability to provide customized solutions through OEM and ODM services. This is particularly vital for industries with niche requirements, such as specific particle sizes for high-end plastics or unique heat-resistance profiles for color asphalt. Their production processes are strictly aligned with international safety and quality standards, ensuring that every batch of pigment is environmentally friendly and compliant with global export requirements.

Innovation Through Laboratory and Technical Support

At the heart of Xuantai’s operations is a state-of-the-art laboratory dedicated to testing and quality assurance. This facility is not merely for internal checks; it serves as a collaborative space for clients. Xuantai’s technical team works closely with customers to analyze their specific application environments–whether it be the pH levels of a cement mix or the processing temperatures of a plastic extruder. This scientific approach ensures that the pigment provided is optimized for the intended result.

The company’s commitment to technical transparency is further evidenced by their participation in major international exhibitions. These events serve as platforms for Xuantai to showcase their latest innovations and hold valid certifications, such as ISO 9001, TUV and SGS, which provide third-party verification of their management and production quality. By maintaining an active presence in the global trade community, Xuantai stays at the forefront of industry shifts, ensuring their technology remains relevant to modern challenges.

Summary

By focusing on product quality, technical innovation, and customer satisfaction, Baoji Xuantai Pigment Technology Co., Ltd. has built a reputation that transcends simple commerce. For businesses seeking to elevate their products with superior color and durability, the Xuantai quality standard offers a reliable path forward in an ever-changing industrial world.

To learn more about their full range of inorganic pigments and technical services, visit their official website: https://www.xt-pigment.com/

This article was originally published by IssueWire. Read the original article here.