(Isstories Editorial):- Xian, Shanxi Jan 26, 2026 (Issuewire.com) – What happens when a coastal solar farm is battered by salt-laden winds and torrential rain, only for the mounting system to fail because a tiny sealing component couldn’t handle the pressure? Or what if a high-rise aluminum facade begins to leak just three years after completion, leading to millions in structural repairs, all because of a compromised joint? In the rapidly advancing landscape of global infrastructure, the integrity of fastening systems has transitioned from a minor engineering detail to a critical safety and longevity factor.

As construction environments become increasingly volatile due to climate change and industrial expansion, the reliance on high-performance sealing components has never been more pronounced. A Chinese Verified EPDM Flat Metal Washer Company like Fasto Industrial Co., Ltd. (Fasto) is currently at the forefront of this evolution, addressing the sophisticated needs of the building and energy sectors. An EPDM flat metal washer is essentially a precision-engineered sealing component that combines the structural rigidity of a metallic carrier with the resilient, weather-resistant properties of Ethylene Propylene Diene Monomer (EPDM). This dual-material architecture ensures that when a screw is driven into a surface, the washer creates an airtight and watertight seal, preventing moisture ingress and protecting the underlying structure from premature degradation.

Fastening Standards in Global Infrastructure

More on Isstories:

- Reliable Sealing Solutions: OEM EPDM Flat Metal Washer Producer From China To Showcase at Kaztoolexpo

- Chinese Verified EPDM Flat Metal Washer Company VS Standard Plastic Alternatives

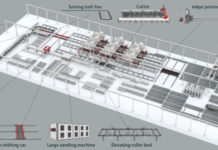

- Pioneering Smart Factories: CCIG Leads with Global Leading Automated Flexible Sheet Metal Line Production

- The Future of Smart Factories: Insights from CCIG, a China Top Intelligent Automation Platform Factory

- What Makes a High Quality International Standard CNC Equipment Supply Factory Reliable for Global Tenders?

The global fastener market is undergoing a significant shift toward specialized materials that can withstand multi-decade life cycles. Industry analysts note that the rise in large-scale renewable energy installations, particularly solar PV systems and coastal wind farms, has created a demand for components that exceed traditional durability benchmarks. In these high-exposure environments, the traditional “one size fits all” approach to hardware is being replaced by engineered solutions.

Modern architectural trends, such as complex aluminum façades and high-load steel structures, require fastening systems that can manage thermal expansion and contraction without losing seal integrity. The market is moving away from generic hardware toward verified manufacturers that provide documented performance metrics. This trend is driven by more stringent building codes worldwide, including Eurocodes and ASTM standards, which emphasize the long-term seismic and environmental resilience of building envelopes. Consequently, the role of a reliable EPDM flat metal washer company has become indispensable in ensuring that the total cost of ownership for a project remains low by avoiding costly maintenance and structural failures.

Advanced Engineering of EPDM Flat Metal Washers and Specialized Applications

The technical superiority of an EPDM flat metal washer lies in its material composition and bonding precision. Unlike standard washers, these components are designed to handle extreme temperature fluctuations, ranging from intense desert heat to freezing high-altitude conditions. The EPDM layer is ozone and UV resistant, ensuring it does not become brittle or crack over time–a common failure point in inferior sealing products.

Fasto‘s product range highlights the diversity required in modern engineering. For instance, the integration of EPDM flat metal washer solutions in copper sealing applications provides an essential barrier in electrical and plumbing systems where thermal conductivity and leak prevention are paramount. Furthermore, the development of specialized stainless steel spring lock washers and Mylar flat variations allows for precise tension management in high-vibration environments. These products are not merely accessories; they are critical interfaces in coastal roofing and solar mounting systems. In PV installations, where wind loads create constant dynamic stress, the EPDM flat metal washer maintains a persistent seal against the panel frames, protecting the electrical integrity of the system. By refining the interface structure and focusing on metallurgical bonding, a leading EPDM flat metal washer company ensures that the washer works in harmony with bimetal self-drilling screws to eliminate issues like hydrogen embrittlement and galvanic corrosion.

Comparing EPDM Metal Solutions with Standard Plastic Alternatives

When evaluating sealing options, project managers often face the choice between high-performance metal-bonded EPDM washers and standard plastic or nylon alternatives. While plastic washers offer a lower initial procurement cost, the long-term implications of their use can be catastrophic in industrial settings. Plastic alternatives are highly susceptible to “creep” or cold flow, where the material deforms under constant pressure, leading to a loss of torque and a compromised seal. In contrast, an EPDM flat metal washer utilizes the metal backing to distribute load evenly, ensuring the EPDM element remains compressed and functional for the duration of the structure’s life.

From a production and quality perspective, standard plastic components often lack the rigorous certification required for critical infrastructure. A verified EPDM flat metal washer company operates under strict quality management systems such as ISO 9001 and IATF 16949. This ensures that every EPDM flat metal washer produced meets international standards like DIN, ASTM, and JIS. The performance gap becomes even more evident in “high-load” environments. Plastic tends to degrade rapidly under UV exposure, losing its elastic properties within a few years. An EPDM flat metal washer, however, is engineered for longevity. The failure of a single washer can lead to water damage, mold, and structural rust, which can cost thousands of times the price of the original component. This serves as a vital reminder to industry participants: the use of sub-standard fastening components is a false economy that risks both reputation and safety.

Strategic Considerations for Industry Stakeholders

The selection of a EPDM flat metal washer company should be based on a holistic view of quality assurance. Reliability in global construction and energy projects is non-negotiable. Leading manufacturers now provide full sets of testing reports by SGS, alongside CE and ETA certifications, to verify torque and tensile strength. As the industry moves toward more sustainable and durable building practices, the focus remains on the “interface”–the point where the fastener meets the material.

Choosing a high-performance EPDM flat metal washer is a proactive step in mitigating risks associated with demanding environments. For engineers and distributors, the priority is shifting toward transparency in the supply chain and the verification of metallurgical bonding processes. As we look toward the future of industrial fastening, it is clear that the transition from basic plastic alternatives to verified metal-EPDM hybrids is not just a trend, but a necessary standard for global excellence.

For more information on high-performance fastening solutions, visit: https://www.fastoscrews.com/.

Fasto Industrial Co., Ltd.

[email protected]

+86-029-81165337

Room A-907, Greenland Center, NO.9 Jinye Road, Yan Ta District, Xi’an, China

https://www.fastoscrews.com/

This article was originally published by IssueWire. Read the original article here.