(Isstories Editorial):- Xian, Shanxi Jan 26, 2026 (Issuewire.com) – The expansive halls of Messe Stuttgart serve as a premier destination for global industrial innovation, drawing thousands of engineering experts, international distributors, and construction professionals to witness the latest advancements in fastening technology. As one of the world’s most influential trade fairs for the fastener and fixing industry, the event provides a critical barometer for market trends and technical excellence. Amidst the highly specialized displays of automotive and aerospace components, a significant amount of professional attention consistently focuses on the versatility of essential hardware.

It was within this high-level environment that Fasto Industrial Co., Ltd. established a distinct impression. Positioned as a China Leading Professional Multi-purpose Screws Producer, the company demonstrated how modern multi-purpose screws have evolved far beyond simple wood fasteners. These precision-engineered components are now designed with advanced thread geometries and high-tensile materials, allowing them to perform reliably across diverse substrates including timber, masonry, and thin-gauge metal, effectively reducing the need for multiple specialized fastener types on a single job site.

Strategic Market Presence and Industry Leadership

More on Isstories:

- Haris Vitalaki Presents Know No Studies: A Poetic Exploration of Freedom, Thought, and Inner Truth

- Bimetal vs Carbon Steel: Insights From China Leading Bimetal Self Drilling Screws Manufacturer Fasto

- Customized Collated Screws Manufacturer From China: Fasto’s Automatic Driving System Solutions

- China Leading Professional Multi-purpose Screws Producer Highlights From MESSE STUTTGART

- CarzRent.com Announces Upcoming Cryptocurrency Payments for Car Rentals

Fasto’s presence at high-caliber international exhibitions like Messe Stuttgart is part of a long-standing commitment to global engagement. For years, the company has maintained a consistent and strategic participation in major trade fairs, a practice that underscores its deep commitment to industry monitoring and market intelligence. By engaging directly with international engineers, Fasto captures real-time feedback on evolving building codes and environmental requirements.

This long-term engagement allows the producer to anticipate shifts in the global supply chain, ensuring that their manufacturing output aligns with the rigorous demands of modern infrastructure projects. This proactive approach to market dynamics has solidified the brand’s reputation as more than just a manufacturer, but as a knowledgeable partner capable of navigating the complexities of international hardware standards.

Technical Innovation in Multi-purpose ScrewsOptimized Design for Diverse Applications

The technical discussions at such professional forums often center on the specific performance characteristics of their multi-purpose screws. Unlike standard hardware, these products feature optimized tip designs–such as the needle-point or specialized cutting notches–that prevent wood splitting while ensuring rapid engagement in denser materials. The “multi-purpose” designation is earned through meticulous heat treatment processes and material selection, including high-grade carbon steel and stainless steel options.

For projects requiring aesthetic or specialized finishes, Fasto offers solutions such as the antique brass round head wood screw. These products are engineered for high-end joinery where both visual appeal and structural self-tapping capability are required. The ability to integrate features of chipboard screws and wood screws into a single multi-purpose design reflects the brand’s focus on simplifying site operations for the end-user.

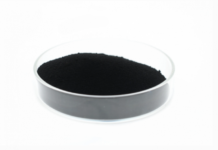

Advanced Coating Technology and Durability

In demanding environments, such as coastal roofing or solar PV installations, the durability of these fasteners is further enhanced by sophisticated protective coatings. Fasto provides a comprehensive suite of finishes, ranging from traditional electroplating and phosphate to high-performance solutions like Ruspert, mechanical galvanization, and Hot Dip Galvanizing (HDG). These coatings are engineered to resist oxidation and chemical corrosion, ensuring the structural integrity of the fastening system over decades of exposure.

Efficiency through Collated Systems

One of the standout product categories discussed by industry professionals is the collated screw systems. By offering multi-purpose screws in galvanised collated strips, Fasto addresses the construction industry’s growing need for “rapid-fix” solutions that reduce labor costs without compromising on grip strength or alignment. Whether it is a Phillips pan head self-tapping variant for interior cabinetry or a heavy-duty timber fastener, the emphasis remains on precision and installation speed.

Comprehensive Capability: A Single Source for Fastening Solutions

Beyond the technical specifications of the hardware, the service model supporting these products is a key pillar of Fasto’s competitive advantage. Operating as a single-source provider, the company manages a vast portfolio that includes rivets, bolts, washers, anchors, and customized components alongside their core screw lines. This comprehensive capability is particularly valuable for large-scale energy and construction projects where logistical simplicity is essential.

By integrating manufacturing, specialized coating, and quality control under one roof, the company ensures a level of consistency that is often lost when sourcing from multiple vendors. This holistic approach to hardware production is what allows a multi-purpose screws producer to maintain the strict tolerances required for high-performance Bimetal Self-Drilling Screws while simultaneously producing high-volume commercial fasteners in materials ranging from stainless steel and steel to titanium and copper.

Future Trends and the Global Hardware Landscape

The evolution of the global fastener industry is currently marked by a transition toward smarter, more sustainable, and highly adaptable components. As urban development becomes more complex and renewable energy infrastructure expands, the reliance on high-performance multi-purpose screws is expected to grow. The industry is seeing a clear trend toward materials like titanium and specialized alloys for niche applications, alongside a universal demand for coatings that meet stricter environmental regulations.

In this rapidly changing landscape, the role of a dedicated multi-purpose screws producer becomes increasingly vital. Fasto Industrial Co., Ltd. exemplifies this role by bridging the gap between traditional manufacturing excellence and modern engineering requirements. By focusing on multi-purpose screws that offer both versatility and uncompromising strength, the company contributes significantly to the safety and efficiency of global construction. As the industry looks toward a future of more integrated and resilient building systems, the contributions of leading Chinese suppliers will continue to be a cornerstone of international industrial progress.

Discover more information about high-performance fastening solutions, visit: https://www.fastoscrews.com/.

Fasto Industrial Co., Ltd.

[email protected]

+86-029-81165337

https://www.fastoscrews.com/

This article was originally published by IssueWire. Read the original article here.