(Isstories Editorial):- Jiangmen, Guangdong Jan 27, 2026 (Issuewire.com) – Understanding the Industry Landscape and Global Trends

The global portable cooler market is currently undergoing a transformation driven by two primary factors: material innovation and the “outdoor lifestyle” boom. Consumers and professional users are moving away from disposable, low-quality EPS foam coolers toward high-durability, rotomolded alternatives. This shift has placed a premium on suppliers who can integrate heavy-duty mobility features–such as oversized, all-terrain wheels and telescopic handles–without compromising the airtight seal necessary for ice retention. In the evolving landscape of outdoor recreation and professional cold-chain logistics, the demand for high-performance insulation solutions has seen a significant uptick. The wheeled cooler, a versatile piece of equipment is designed to maintain internal temperatures for extended periods while offering the mobility required for diverse environments.

For businesses and distributors, the challenge lies not just in finding a product, but in identifying a Certified Wheeled Cooler Supplier capable of meeting rigorous international standards. A wheeled cooler is more than just a plastic box on wheels; it is a precision-engineered tool utilizing advanced thermal dynamics to protect perishables in high-heat conditions, making the selection of a manufacturing partner a critical strategic decision.

More on Isstories:

- Farm Fun – Animal Parking Game: Blending Farm Logic,Spatial Strategy and Immersive Puzzle Play in a 3D Casual Experience

- China Top Tool Storage Box Provider: Comparing AHIC’s Industrial Solutions with Global Competitors

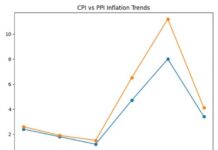

- Controlling Inflation, Why America’s Inflation Problem Is Structural

- Grand Millennium Muscat’s exclusive Ramadan Enchanting Iftar and Suhoor Experiences

- China Trending Tool Box Provider: AHIC’s Commitment to ISO and CE Certification

For a supplier to remain competitive in this space, they must navigate a complex web of environmental regulations and food safety standards. The industry trend is moving toward “multi-functionalism,” where coolers are expected to serve as mobile workstations, storage units, and even protective cases for sensitive cargo. Consequently, the manufacturing complexity has increased, requiring factories to possess not only advanced machinery but also a sophisticated understanding of polymer science and structural engineering.

Essential Criteria for Selecting a High-Quality Factory

When evaluating a potential manufacturing partner, price should never be the sole metric. A reliable factory must demonstrate excellence across three core pillars: production technology, compliance, and customization capability.

Rotomolding Excellence and Material Integrity

The hallmark of a premium wheeled cooler is the rotational molding process. Unlike injection molding, rotomolding creates a seamless, stress-free part with uniform wall thickness and reinforced corners. A top-tier factory should utilize high-density polyethylene (LLDPE) that is UV-resistant and food-grade. Prospective partners should inquire about the “PU foaming” process–the insulation layer. The density and uniformity of this foam determine whether a cooler maintains ice for two days or ten. A factory that provides transparent data on their foam injection technology is often a sign of superior quality control.

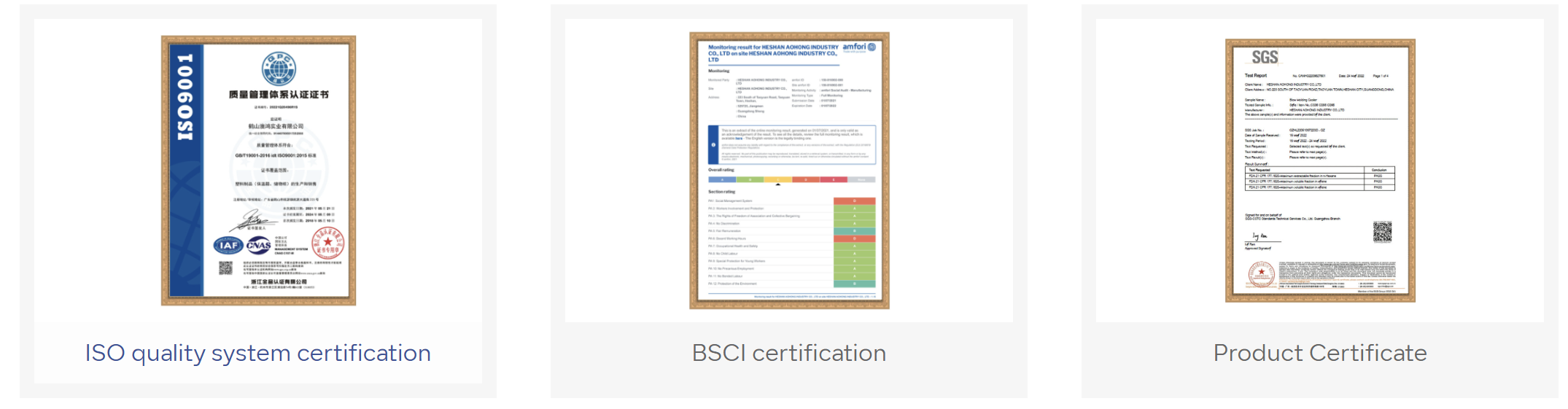

Global Compliance and Ethical Certification

In an era of transparent supply chains, certifications are the most objective proof of a factory’s reliability. A reputable supplier should hold internationally recognized credentials such as ISO 9001 for quality management systems. Furthermore, social responsibility audits like BSCI (Business Social Compliance Initiative) or SEDEX are non-negotiable for brands looking to sell in Western markets. These certifications ensure that the products are manufactured under ethical labor conditions, which mitigates brand risk for the distributor.

Technical Patents and Innovation

A factory that merely copies existing designs is a liability. Leading suppliers invest heavily in Research and Development (R&D). Look for partners who hold a significant portfolio of patents. This indicates a proactive approach to solving common user pain points, such as vacuum release valves, heavy-duty latches, or specialized drainage systems.

Heshan Aohong Industry: A Case Study in Manufacturing Excellence

A prime example of a manufacturer that aligns with these rigorous standards is Heshan Aohong Industry Co., Ltd. Established in 2010, the company has positioned itself as a comprehensive hub for the research, development, and service of rotomolded products. By focusing on the intersection of durability and thermal efficiency, they have become a benchmark for what a Certified Wheeled Cooler Supplier should represent in the modern market.

Core Competencies and Technical Innovation

The technical backbone of Aohong’s success lies in their mastery of the rotomolding process. Their wheeled coolers are engineered to withstand extreme physical impact, making them suitable for both rugged outdoor adventures and industrial cargo transport. A key differentiator is their commitment to “all-terrain” functionality. Their wheeled models feature integrated axle systems and high-traction wheels designed to navigate sand, gravel, and mud without mechanical failure.

Beyond physical durability, the thermal performance is bolstered by specialized gasket seals and thick-wall insulation. The integration of “fruit reports” and certifications such as CE, ROHS, and FCC further validates the safety and chemical compliance of their materials, ensuring that the coolers are safe for direct contact with food and beverages.

Comprehensive Quality Assurance and Global Credentials

The strength of a supplier is often reflected in their audit history. Heshan Aohong Industry maintains a robust portfolio of certifications, including BSCI, SEDEX, and ISO 9001. These are not merely badges but operational frameworks that dictate their daily production routines. With more than 140 patents, the company demonstrates a continuous cycle of innovation, ensuring that their OEM and ODM partners receive products that are legally protected and technologically advanced.

Conclusion: Securing a Competitive Advantage

Selecting the right supplier is an investment in your brand’s reputation. A wheeled cooler that fails in the field–whether through a broken handle or poor insulation–can result in costly returns and damaged consumer trust. By prioritizing factories that offer a combination of rotomolding expertise, ethical certifications like BSCI, and a proven track record of innovation, businesses can ensure long-term success.

In the competitive landscape of 2025 and beyond, the partnership between a brand and its manufacturer must be built on technical transparency and shared quality standards. Suppliers like Heshan Aohong Industry exemplify the professional maturity required to navigate this demanding industry, providing the reliability that global markets expect.

For more information on high-performance rotomolded solutions and certified manufacturing, visit: https://www.ahiccooler.com/

This article was originally published by IssueWire. Read the original article here.