(Isstories Editorial):- Jiangmen, Guangdong Jan 26, 2026 (Issuewire.com) – The global kitchenware market has undergone a significant transformation over the past decade, shifting from a focus on mass-produced, disposable items to high-performance, sustainable culinary tools. As consumer awareness regarding food safety and material longevity grows, international distributors and retailers are increasingly prioritizing sourcing strategies that emphasize metallurgical integrity. In this evolving landscape, 304 Stainless Steel Sets have emerged as the industry standard for professional and home kitchens alike, offering a balanced combination of corrosion resistance, thermal efficiency, and aesthetic appeal. For global brands seeking to maintain a competitive edge, the selection of a manufacturing partner involves more than just evaluating unit costs; it requires a deep dive into technical expertise, production scalability, and compliance with international quality benchmarks.

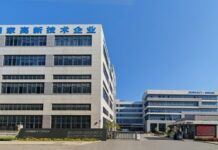

The demand for premium cookware is particularly evident in Western and emerging markets, where “home-centric” lifestyles have revitalized interest in professional-grade equipment. This trend has placed a spotlight on Jiangmen Xinhui Jincui Metalware Co., Ltd., an organization that has spent over two decades refining the art of stainless steel fabrication. Established in 2003 in Jiangmen, Guangdong–a region synonymous with metalware excellence–the company has built a reputation for delivering sophisticated solutions that meet the rigorous demands of global supply chains. By focusing on the inherent strengths of 18/8 (304 grade) stainless steel, they provide the foundation upon which many international brands build their premium product lines.

Technical Precision in Material Selection

More on Isstories:

- Why Global Brands Choose JC Cookware for 304 Stainless Steel Sets

- Global Customizable PET Film: Why ACS Stands Out In Quality And Versatility

- Which Chinese Supplier Provides 304 Stainless Steel Cookware Sets for Global Brands?

- A Buyer’s Guide to Sourcing From Linyang, One of China’s Best Cover Tarpaulin Factories With ISO Certifications

- A Declaration of Economic Independence

The decision to utilize 304 stainless steel as the primary material for high-end cookware sets is rooted in its chemical composition. Comprised of approximately 18% chromium and 8% nickel, this austenitic alloy provides an exceptional barrier against oxidation and organic acids found in food. For global brands, this means fewer product returns and higher customer satisfaction. At the Jiangmen-based facility, which spans an impressive 40,000 square meters, the processing of these materials is handled with industrial-grade precision.

Beyond the raw material, the architectural integrity of a saucepan or casserole depends on its construction method. JC Cookware specializes in two primary categories that dominate the premium market: encapsulated bottom and whole-clad structures. The encapsulated bottom technology involves a sophisticated impact-bonding process where an aluminum core is sandwiched between layers of stainless steel. This ensures rapid and even heat distribution, eliminating the “hot spots” that often plague inferior products. For brands targeting the mid-to-high-end consumer segment, these sets offer a reliable entry point into the professional-performance category.

Advanced Manufacturing and Scalability

A critical factor for international procurement teams is the manufacturer’s ability to scale production without compromising on the minute details of craftsmanship. Operating with a capacity that exceeds 3,000,000 pieces annually, the facility utilizes advanced machinery that includes large-scale impact bonding units and complex braze welding systems. This technological infrastructure allows for the consistent output of diverse items, ranging from standard casseroles and fry pans to specialized tools like asparagus pots, pasta pots, and seafood pans.

The integration of advanced punching and shearing facilities ensures that every rim is smooth and every handle attachment is secure. In the context of global trade, consistency is the hallmark of quality. When a brand orders thousands of units for a seasonal launch, they require the 3,000th piece to be identical in finish and performance to the first. This level of repeatability is achieved through a combination of automated precision and a workforce that carries 20+ years of specialized experience in the Guangdong metalware sector.

Aligning with Global Safety and Ethical Standards

In the modern marketplace, a product’s value is inextricably linked to the ethics of its production. Global brands are under constant scrutiny regarding their supply chains, making certifications like ISO 9001:2015 and BSCI (Business Social Compliance Initiative) non-negotiable. JC Cookware’s adherence to these standards provides a layer of security for international partners. The ISO certification ensures a rigorous quality management system is in place, covering everything from raw material inspection to final packaging.

Furthermore, the BSCI audit reflects a commitment to fair labor practices and safe working conditions. This alignment with international social responsibility standards allows global brands to market their products with confidence, knowing that their manufacturing partner operates with transparency. This synergy between technical quality and corporate responsibility is often the deciding factor for heritage brands in Europe and North America when selecting a long-term manufacturing ally.

Versatility Across Culinary Applications

The utility of a cookware set is measured by its performance across different heat sources and cooking styles. The modern kitchen is diverse, utilizing gas, electric, and increasingly, induction cooktops. The 304 stainless steel products manufactured here are designed with this versatility in mind. For instance, the multi-ply whole-clad series offers heat conductivity not just at the base, but up the sidewalls of the vessel. This creates an oven-like environment within the pot, which is essential for techniques like braising or slow-simmering.

Product application scenarios extend beyond the domestic kitchen. The durability of heavy-gauge stainless steel makes these sets suitable for the “prosumer” market and light commercial use. Whether it is a stockpot designed for long hours of simmering in a boutique bistro or a sleek milk pot for a minimalist home kitchen, the engineering remains focused on ergonomic balance and thermal stability. The inclusion of specialized items like steamers and woks within the production portfolio demonstrates an understanding of both Eastern and Western culinary requirements, allowing brands to curate sets that cater to specific regional tastes.

Strategic Partnership and Win-Win Growth

The philosophy of “win-win business” is more than just a corporate slogan in the context of international manufacturing; it is a practical necessity. Global brands require a partner who can provide design input, material expertise, and reliable logistics. With over two decades of experience, the team at JC Cookware understands the nuances of export-grade packaging and the logistical requirements of shipping millions of units across oceans.

The invitation for international clients to visit the 40,000-square-meter facility is a testament to the company’s confidence in its operations. Witnessing the transition from raw steel sheets to polished, high-performance cookware provides a clear perspective on the craftsmanship involved. For brands looking to innovate, such as developing unique handle designs or custom lid configurations, having access to an established R&D and manufacturing base in Jiangmen is a significant strategic advantage.

The Future of Stainless Steel in the Global Market

As the industry moves toward 2026 and beyond, the emphasis on durability will only intensify. The environmental impact of kitchenware is being scrutinized, and “forever” materials like 304 stainless steel are being favored over non-stick coatings that may degrade over time. The inherent recyclability of stainless steel also aligns with the circular economy goals of many global corporations.

By maintaining a focus on high-quality fabrication and staying abreast of technological advancements in metal bonding and finishing, manufacturers in the Jiangmen cluster continue to serve as the backbone of the global kitchenware supply chain. For the brands that choose these high-standard sets, the result is a product line that stands the test of time, both in the kitchen and in the competitive retail marketplace.

The evolution of the culinary industry suggests that quality is the only sustainable path forward. As international buyers look for reliability in their supply chains, the combination of advanced technology, certified management systems, and a deep understanding of metallurgical properties becomes the defining characteristic of a successful partnership. The commitment to excellence in the production of stainless steel vessels ensures that global culinary standards continue to rise, providing chefs and home cooks with the tools they need to succeed.

Investing in a partnership that values craftsmanship and service is the most effective way for brands to ensure their longevity. By leveraging the expertise of an established manufacturer that has spent twenty years perfecting the production of various cookware–from the standard fry pan to the specialized stockpot–global companies can focus on what they do best: building relationships with their customers. The synergy between a brand’s vision and a manufacturer’s technical execution is what ultimately brings world-class kitchenware to tables across the globe.

To learn more about the technical specifications and the wide range of available cookware solutions, interested parties are encouraged to explore the comprehensive offerings provided by the team in Jiangmen. Detailed information regarding encapsulated bottom technology, whole-clad constructions, and custom manufacturing capabilities can be found by visiting the official resource for professional cookware at https://jincui.com/.

This article was originally published by IssueWire. Read the original article here.