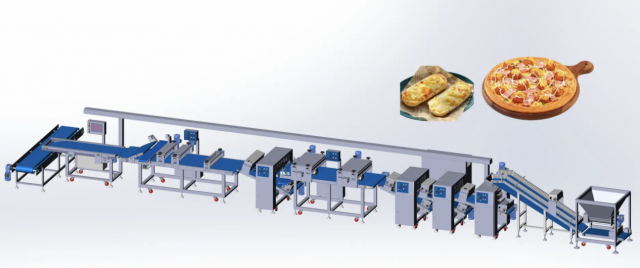

(Isstories Editorial):- Shanghai, China Jan 26, 2026 (Issuewire.com) – As global consumption of pizza continues to expand across retail, foodservice, and frozen food channels, manufacturers face increasing pressure to scale output while maintaining consistency and process stability. In this context, the Best Automatic Pizza Production Line Factory is no longer defined solely by nominal capacity. Instead, it is evaluated by how effectively automation integrates with dough behavior, product consistency, and long-term operational reliability. An Automatic Pizza Production Line typically connects dough handling, sheeting, forming, docking, and conveying into a continuous workflow. Within this evolving industrial environment, CHENPIN FOOD MACHINE CO., LTD has gained attention for developing pizza production systems that emphasize controlled dough processing rather than generic automation speed.

Global Pizza Market Growth and the Shift Toward Process-Oriented Automation

Pizza has evolved from a regional specialty into a globally standardized food category. Demand continues to grow across Europe, North America, Asia, and emerging markets, driven by urbanization, the expansion of quick-service restaurant chains, and the rising consumption of frozen and ready-to-bake foods. As volumes increase, manufacturers face structural challenges that manual or semi-automatic operations struggle to address consistently.

More on Isstories:

- The Most Reliable Automatic Pizza Production Line Factory, CHENPIN, Delivers Scalable Solutions for Global Demand

- Why Do Global Integrators Choose HUAIN as Their Professional Wireless Conference Microphone System Supplier?

- Elevating Dessert Production: CHENPIN Present the Future Leading Automatic Egg Tart Production Line Company’s Innovation

- What Makes HUAIN the China Best AV Solution Provider in 2025?

- Newest Design Household waste bin manufacturer vs. Conventional Design Suppliers

Automation is therefore increasingly adopted not only to reduce labor dependency, but also to stabilize daily output and reduce variability. However, as production scales, flexibility becomes equally important. Modern pizza lines must process different dough formulations, hydration levels, and base dimensions while maintaining predictable baking behavior. This shift has placed greater emphasis on equipment suppliers that understand dough mechanics, not only throughput metrics.

CHENPIN’s Position in Automated Dough-Based Food Equipment

Established in 2010, CHENPIN FOOD MACHINE CO., LTD builds upon a technical foundation developed by a Taiwan-based engineering team with more than three decades of experience in food equipment design prior to the company’s formal founding. The company has consistently focused on automated solutions for dough-based and flatbread products, including tortillas, paratha, Laminated pastry, and pizza bases.

CHENPIN operates across research and development, manufacturing, system integration, and after-sales support. This integrated structure allows production feedback from industrial users to inform mechanical refinement and process optimization. Over time, the company has accumulated patented technologies related to dough sheeting, forming, and controlled conveying, which now form the technical backbone of its pizza production lines.

Rethinking What Defines an Automatic Pizza Production Line

An automatic pizza production line is often described as a sequence of machines performing dough reduction, cutting, and transfer. In practice, long-term performance depends on how well each stage manages dough stress, alignment, and structural integrity. Inconsistent thickness, uncontrolled gluten tension, or unstable conveying can lead to product deformation, uneven baking, and increased waste.

CHENPIN’s approach places sheeting and dough conditioning at the center of line design. Rather than relying on single-step pressing, its pizza lines use staged sheeting and continuous reduction to achieve thickness control while preserving dough structure. This design logic reflects experience gained from laminated flatbread and layered pastry production, where dough behavior is highly sensitive to mechanical force.

Process Engineering Highlights in CHENPIN Pizza Production LinesDough Conveying and Automatic Alignment

After mixing and controlled resting, fermented dough is transferred via a dedicated conveying system designed to maintain structural integrity. Before entering the sheeting section, automatic alignment mechanisms correct dough positioning. This step ensures uniform entry into subsequent rollers, reducing uneven stretching and improving downstream thickness consistency. The conveying system prioritizes stability over speed, supporting continuous operation with reduced manual correction.

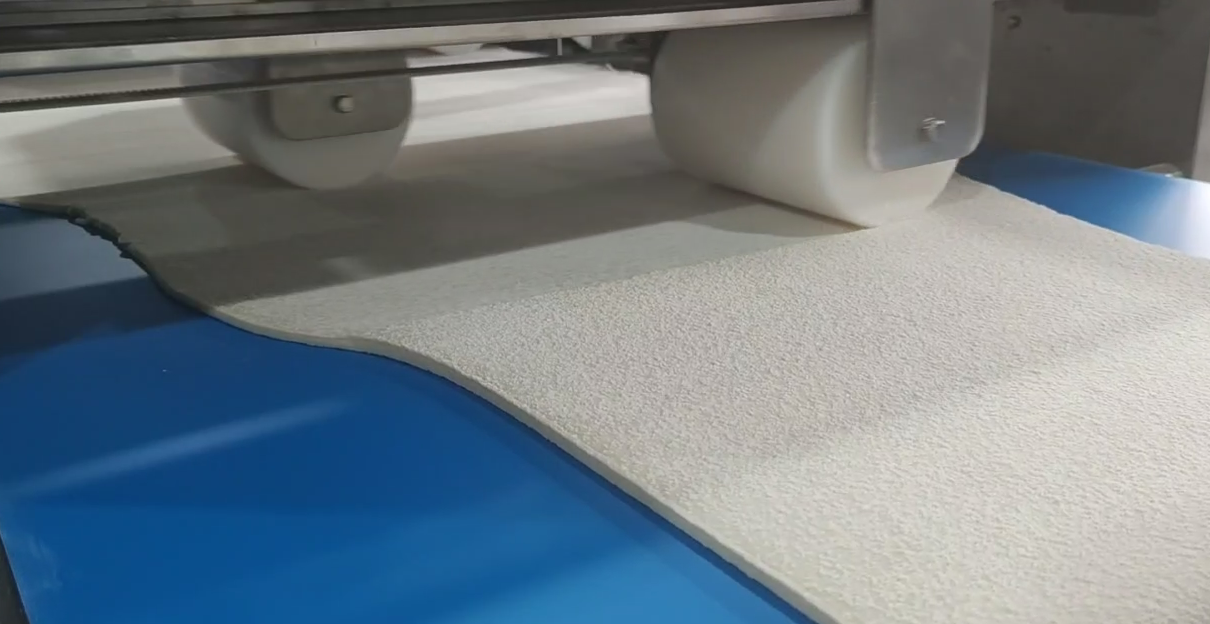

Pre-Sheeter and Continuous Sheeting Rollers

The pre-sheeter initiates gradual dough reduction, preparing the gluten network for controlled extension. Continuous sheeting rollers then reduce thickness in stages rather than through abrupt compression. This method allows the dough sheet to widen naturally while minimizing internal stress accumulation.

Non-sticking roller surfaces enable stable processing of high-hydration doughs, which are increasingly common in modern pizza formulations. By reducing adhesion and surface tearing, the system supports longer production runs with fewer interruptions for cleaning or adjustment. These design features allow the line to handle both green and pre-fermented dough with consistent results.

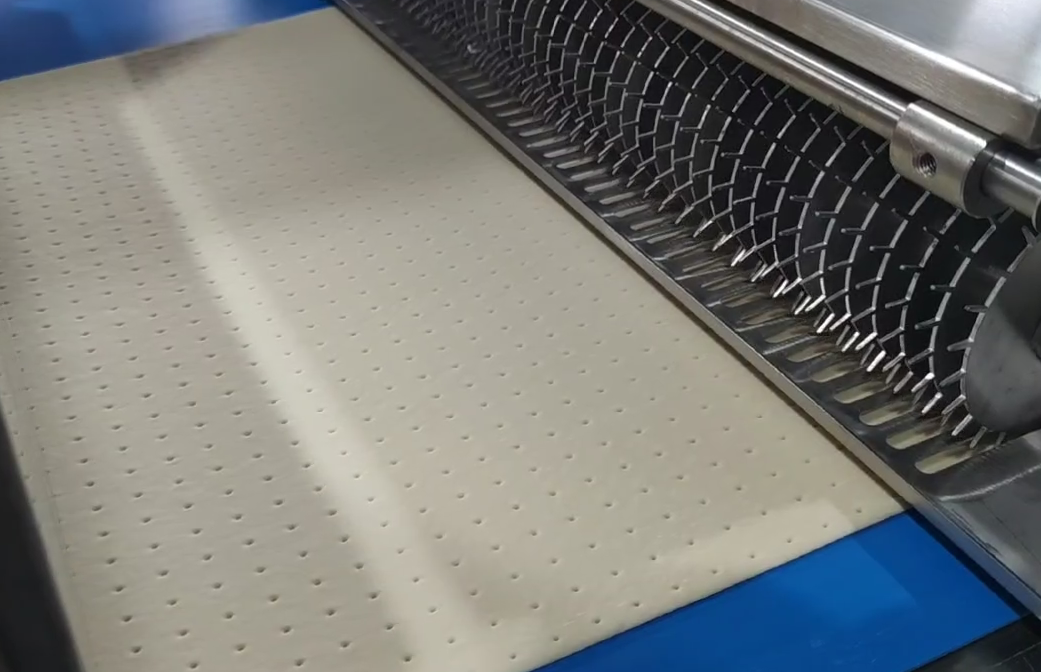

Disc Cutting and Docking Integration

Following sheeting, cross rollers provide secondary thickness calibration, compensating for directional stress introduced earlier in the process. Disc cutting then forms standardized pizza bases, while integrated docking perforates the surface to control gas expansion during baking. This combination reduces surface bubbling and supports predictable oven performance, particularly in frozen or par-baked applications.

Trim waste generated during cutting is automatically collected and returned through a closed-loop system, improving material utilization without disrupting line flow.

Application Scenarios Across Pizza Production Models

CHENPIN’s automatic pizza production lines are applied in a range of industrial settings. Frozen pizza manufacturers benefit from uniform base dimensions and stable moisture distribution, which are critical for freezing efficiency and final bake quality. Central kitchens and foodservice suppliers use the lines to produce standardized bases that integrate smoothly with high-speed topping and baking systems. Retail and private-label producers value the ability to adjust diameter and thickness parameters to meet regional specifications without major mechanical changes.

Beyond pizza, CHENPIN’s experience with tortillas, layered flatbreads, and laminated pastries strengthens its ability to address dough-related challenges that general automation suppliers may overlook.

Evaluating Suitability for Industrial Buyers

For professional buyers, the relevance of an automatic pizza production line depends on operational goals rather than headline capacity. Facilities seeking to scale output while reducing variability, managing high-hydration dough, or stabilizing frozen product performance are more likely to benefit from sheeting-based systems. Lines designed with staged reduction and alignment control tend to offer better long-term consistency than solutions focused solely on pressing speed.

CHENPIN’s equipment is therefore most relevant for manufacturers transitioning from semi-automatic processes to continuous production, or for established producers refining consistency as volumes grow. In such contexts, automation becomes a process control tool rather than a simple labor substitute.

Supporting Scalable Growth Through Engineering Stability

As global demand for pizza and convenience foods continues to rise, manufacturers must balance higher output with predictable quality and operational resilience. Automatic pizza production lines that integrate dough behavior, mechanical stability, and modular scalability are likely to define the next stage of industry development.

By applying long-standing expertise in dough sheeting and forming to pizza production, CHENPIN continues to offer systems that align with industrial production realities. Its emphasis on controlled processing, continuous operation, and practical adaptability positions the company as a relevant option for producers evaluating long-term automation strategies.

For more information about CHENPIN’s automatic pizza production lines and its full range of automated food production equipment, please visit https://www.chenpinmachine.com/.

CHENPIN FOOD MACHINE CO., LTD

[email protected]

+86 021-57674551

No.61 Lane, Dongshe Road 129, Songjiang District, Shanghai,China

https://www.chenpinmachine.com/

This article was originally published by IssueWire. Read the original article here.