(Isstories Editorial):- Wuxi, Jiangsu Jan 21, 2026 (Issuewire.com) – Whiteboard Steel Sheet Sourcing Guide: Best Material for Manufacturing (>4H Hardness)

In the competitive world of educational and office supplies, manufacturers are constantly asking: “What is the best material for manufacturing professional whiteboards?”

If you search online, you will find generic articles listing porcelain, glass, and melamine. But as a factory owner or trader, you aren’t looking for a science lesson. You are looking for profitability, processability, and performance. You need a whiteboard steel sheet that is affordable enough for volume sales but durable enough to prevent customer returns.

More on Isstories:

- PPGI Price Trends 2026 (Updated): Cost Per Ton – Purchasing Guide

- Whiteboard Steel Sheet Sourcing Guide: Best Material for Manufacturing

- EICOP Launches Support HBCU Futures Campaign

- Drums, Discipline – School Pride: The Lakes Show Battle of the Bands Returns to Palm Beach Lakes High School

- SINGI: A Top RCBO Manufacturer for Certified Low-Voltage Protection

While Porcelain (Enamel) is technically the most durable, its high cost and difficult processing make it unsuitable for 90% of the mass market. On the other end, Melamine is too cheap and damages your brand reputation with “ghosting” complaints.

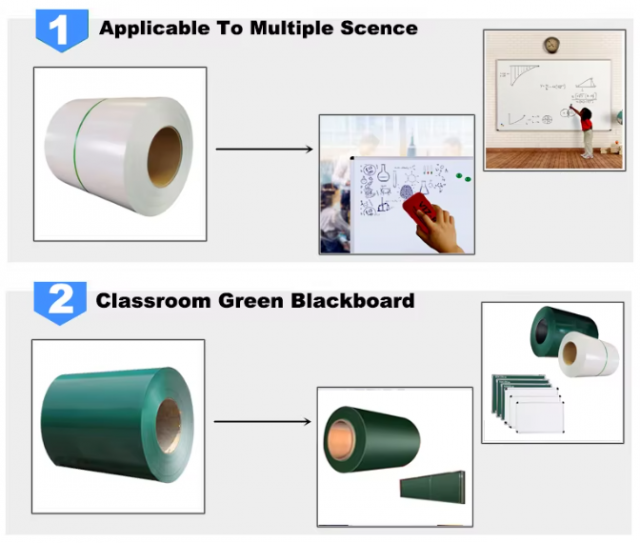

This leaves one clear winner for the B2B industry: High-Quality Whiteboard Steel Sheets (PPGI). In this comprehensive guide, we will analyze why our steel sheets offer the best ROI, share a real success story of a Vietnam factory, and reveal the technical specifications you must demand from your supplier.

Expert Guide: Table of Contents

- 1. Economics: Cost vs. Quality

- 2. Core Tech: The 3-Layer Coating

- 3. Hard Data: Hardness & Gloss

- 4. Manufacturing: Shearing Guide

- 5. Lamination: Glue & Pressing

- 6. Strategy: Thickness Selection

- 7. Ecosystem: Frames & Parts

- 8. Logistics: Yield Calculator

- 9. Case Study: Vietnam Success

1. The Economics of Whiteboard Steel Sheets: Why PPGI Wins

For a manufacturer, the “best” material isn’t just about longevity; it’s about the profit margin. Let’s compare whiteboard steel sheets (PPGI) against other dominant materials.

Material TypeDurabilityProcessing DifficultyCost IndexMarket FitPorcelain (Enamel)Lifetime (Diamond Hard)Very High (Brittle, hard to cut)$$$$$Niche High-End ProjectsWhiteboard Steel Sheet (PPGI)10+ Years (>4H Hardness)Low (Easy to shear/bend)$$ (Sweet Spot)Mass Market (Schools/Offices)Melamine (Resin)< 1 YearLow$Cheap Toys / Temporary

The Verdict: Unless you are equipping a luxury boardroom, the Whiteboard Steel Sheet is the logical choice. It costs a fraction of Porcelain while offering 90% of the performance and is magnetic (unlike Melamine).

2. Not All Whiteboard Steel Sheets are Created Equal

A common mistake new buyers make is purchasing standard construction-grade color steel. This leads to yellowing or ghosting within months. Professional whiteboard steel sheets use a complex 3-Layer System designed for dry-erase performance.

7±2µmTop Acrylic Paint

Writing surface. Determines gloss and erasability.

15±2µmPE Primer

Anchor layer. Prevents peeling during shearing.

5±2µmBack Coating

Protective layer. Prevents glue corrosion.

Why Back Coating is Critical:

If the back coating on the whiteboard steel sheet is too thin, moisture from the glue can penetrate and rust the steel from the inside when laminated to MDF or honeycomb cores. We strictly control a 5±2µm PE back paint to eliminate bubbling risks.

3. Hard Data: Hardness, Gloss & Tolerance

Don’t just take a salesperson’s word for it. Look at the lab data for our whiteboard steel sheets:

- Pencil Hardness: >4H (Standard construction steel is only 2H). High hardness prevents micro-scratches where ink usually gets trapped.

- Erasability (MEK Test): 100 Rubs. We test with Methyl Ethyl Ketone to ensure the paint doesn’t dissolve or fade.

- Gloss Level: 85±10 (60° reflection). The optimal balance for brightness without blinding glare.

Precision Tolerances for Assembly:

- Width Tolerance: +7mm / -0mm (You never receive less width than you paid for).

- Thickness Tolerance: +0.08mm / -0.04mm.

4. Manufacturing Guide: Cutting Whiteboard Steel Sheets

Based on our “Whiteboard Process” training documents, here is how to optimize your production line when processing whiteboard steel sheets:

A. Decoiling (Startups vs. Factories)

If you are just starting, you don’t need an expensive Automatic Decoiler ($3,800+). We recommend a Manual Decoiler which costs only a few hundred dollars. It saves initial capital while getting the job done.

B. Shearing (Cutting) Options

Choosing the right shear depends on your material thickness:

- Pedal Shears: Best for thickness < 0.6mm. Flexible, human-operated, and low cost. Ideal for custom sizes.

- Electric Shears: Recommended for thickness approx. 1mm or higher volume production.

Shearing Machine allows for precise cuts without damaging the 15µm primer layer of the whiteboard steel sheet.5. The “Sticky” Truth: Lamination & Gluing Tips

Delamination (steel peeling off the core) is a common failure. Here is the correct process to ensure a permanent bond when using whiteboard steel sheets:

- Apply Glue: Use a dedicated adhesive. Apply with a brush or spray gun to one side.

- The “Tacky” Phase (Crucial): Do not press immediately! Let the glue cool for 3-4 minutes. Touch it–it should feel slightly sticky but not transfer to your hand.

- Pressing: Bond the whiteboard steel sheet to the core (MDF/Foam).

- Curing: Place a heavy object on the panel and let it sit for 1-2 days to cure fully under pressure.

6. Strategy: Which Thickness Should You Buy?

The thickness of the whiteboard steel sheet determines your cost per square meter. Here is our strategic advice:

ApplicationRecommended ThicknessWhy?School Boards (Green/White)0.30mmStandard for large classrooms. Rigid and flat. Custom Large Projects0.27mm – 0.28mm Requires higher MOQ (8 tons) but saves cost on large runs. Small / Kids Boards0.18mm – 0.20mmCheapest per sqm. Ideal for 30x40cm boards.7. The One-Stop Ecosystem: Frames & Accessories

Sourcing whiteboard steel sheets from one factory and aluminum from another is a logistical nightmare. We provide a consolidated solution:

- Aluminum Profiles: 6063 Alloy, 5.9 meters/piece, 40 pieces/bundle.

- Weight: Standard double-sided frame is ~65g/meter.

- Accessories: Matching ABS Corners and Galvanized Back Plates (0.16mm).

8. Logistics: Calculate Your Yield

As a B2B buyer, you buy whiteboard steel sheets by the ton but sell by the meter. Use this formula to calculate your actual cost:

???? Yield Calculator FormulaMeters Per Ton = 1000 ÷ 7.85 ÷ Thickness(mm) ÷ Width(m)

Insight: Thinner material (e.g., 0.18mm) yields significantly more meters per ton than 0.3mm, reducing your unit cost per board.

9. Case Study: How a Vietnamese Factory Used Our Whiteboard Steel Sheets to SucceedVietnamese whiteboard manufacturer and her factory. From “Shutdown” to “40% Market Share”: A Success Story

The Trap: Our client, a female entrepreneur in Vietnam, left a large corporation to start her own factory. Early on, she faced a crisis: opaque supply chains led to short-weight shipments, and poor-quality whiteboard steel sheets caused severe ghosting issues. Her factory was on the verge of shutdown due to cash flow problems and customer complaints.

The Solution: We stepped in with a 3-step strategy:

1Low MOQ Support: We broke the “8-ton MOQ” rule, allowing her to purchase mixed loads (Mixed whiteboard steel sheets and frames) to free up cash flow.2Korean-Quality Benchmarking: We provided >4H hardness whiteboard steel sheets and developed niche premium products, helping her avoid low-end price wars and compete directly with Korean imports.3Technical Empowerment: We trained her team on how to inspect raw material thickness and tolerances, drastically reducing production waste.

The Result:

40%National Market Share0Quality Complaints

“Deep relationships and differentiated products are key to sustainable growth.”

Stop Paying for “Brand Premium”

You need a partner who understands manufacturing, not just a steel seller. We provide High-Hardness (>4H) Whiteboard Steel Sheets, Matching Frames, and Technical Support in one shipment.

Ready to duplicate this success?

Jiangyin Everest Steel Co., Ltd.

[email protected]

+86-158-5259-6209

22/F, Zhifu Building, No. 299, Tongdu North Road, Jiangyin, Wuxi, Jiangsu

https://everesteel.com/

This article was originally published by IssueWire. Read the original article here.