(Isstories Editorial):- Yongzhou, Hunan Jan 19, 2026 (Issuewire.com) – The demand for highly reliable, thermally stable, and contamination-free materials is increasing as global semiconductor innovation accelerates. China’s Mingrui Ceramic, a leader in this race for technology, is enhancing the value of precision ceramic components for semiconductor industry applications through its unmatched machining skills, top-notch quality management, and innovation momentum. With decades of experience serving engineering sectors that rely on mission-critical ceramic parts, Mingrui Ceramic has become one of Asia’s leading suppliers.

Semiconductor Industry Forecast: Why Precision Ceramics are more important than ever

Semiconductors are the backbone of digital civilization–powering consumer electronics, green energy systems, AI computing hardware, defense platforms, autonomous vehicles, biomedical imaging, and factory automation. Material stability is essential as nodes shrink and processing speed increases. Components must withstand corrosive gasses, thermal shock, exposure to plasma, micro-vibrations, and high vacuum.

More on Isstories:

- Plastic Injection Molding Solutions for High-Precision Manufacturing

- Precision Ceramic Components for Semiconductor Industry: How Mingrui Ceramic Outperforms Other Asian Manufacturers

- Top Custom Ceramic Parts Manufacturer in China 2026: Mingrui Ceramic

- A Guide to Mingrui Ceramic’s Technical Ceramic Parts: How to Choose a Supplier

- How to Evaluate a high purity alumina ceramic supplier: Key Factors Demonstrated by Mingrui Ceramic

Technical ceramics–particularly zirconia, alumina, silicon nitride, and advanced composite blends–are increasingly replacing metal and polymers because they provide:

- Exceptional hardness

- High temperature resistance

- Chemical Inertness

- Low particle emission

- Electrical conductivity or insulation (tuned according to formulation)

- Low expansion coefficients to maintain dimensional stability

Analysts expect that the use of high-precision ceramics in semiconductor fabs is set to increase by over 30% within five years. This will be driven by EUV, chiplet packaging and vacuum transport tools, as well as cleanroom automation.

Mingrui Ceramic is leading the way in this rapidly evolving market.

Mingrui Ceramic: Engineering Beyond Industrial Norms

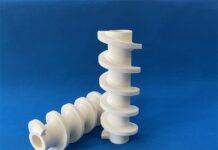

Mingrui Ceramic is a specialist in ultra-precision tight tolerance machining. We offer full-process fabrication based on customer drawings and R&D ideas. The company offers a range of services, from prototype R&D through to OEM volume production:

- Complex shaping

- Surface refinement

- Assembly Integration

- Dimensional Verification via Coordinate Measuring machines (CMMs)

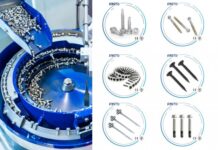

The company’s manufacturing infrastructure includes automated grinding, diamond tooling, laser measurement and digital evaluation equipment.

The performance of this foundation has drawn world-leading semiconductor plants and engineering companies. Mingrui Ceramic is chosen by universities, high-tech companies, and scientific laboratories around the world because it consistently meets structural and tolerance requirements.

Why Mingrui Ceramic outperforms other Asian manufacturers

Only a few ceramic component manufacturers in Asia are at the same level as Mingrui Ceramic. Below are the four main competitive strengths that explain the gap.

1. High Precision Capability and Technical Knowledge

Other suppliers deliver mostly molded components that require costly secondary refinement on the part of customers. Mingrui Ceramics, on the other hand, can perform both Post-sintering Finishing and Green Machining.

- micron-level flatness,

- repeatable parallelism,

- Structure geometry optimization

- Most regional competitors cannot control their tolerance.

This reduces the risk of modification for semiconductor fabs, and also shortens the lead time to qualify.

2. Industry-Leading Certification Ecosystem

Mingrui Ceramic, unlike many Asian suppliers, maintains an industry-wide certification architecture that covers material safety, management standards and traceability. Its credentials include

RoHS, REACH and ISO9001 are all acronyms for MSDS. ISO13485, ISO45001 and SGS are also ISO14001.

This breadth of certification gives OEM clients the confidence that they can rely on global audit compatibility and process reliability. They also get assurances about supply chain transparency, environmental stewardship and long-term compliance.

3. Intelligent Quality Control Infrastructure

Mingrui Ceramic invests heavily into automated manufacturing and digital quality inspection, including

CMM dimensional verification,

Surface roughness sensors

Laser measurement systems

Validation protocols for reliability

The inspection is carried out by specialists, not entry-level workers. This ensures reduced variability and reproducibility of projects over the long term.

These controls are often lacking in competitors who offer low-cost machining, resulting in inconsistent batches or failures during semiconductor qualification.

4. Proven track record with Research Institutes & High-Level Technology User

Mingrui Ceramic is a company with years of experience in serving R&D labs and semiconductor fabs around the world. Mingrui Ceramic is the first choice for many of the top research institutions in the world. This is not because they are concerned about price, but rather because:

- repeatability,

- Tolerance and Integrity

- Clean processing

- and zero-defect validation systems.

Mingrui Ceramic is a leader in high reliability, low particle contamination parts that are essential for vacuum wafer handling systems, EUV systems and electrostatic chucks.

The Applications that Define Mingrui Ceramics’ Strength

Mingrui Ceramics’ precision ceramics have been deployed in semiconductor applications including:

vacuum processing platforms,

wafer carrier tooling,

high-temperature fixtures,

plasma exposure components,

Insulating blocks

Alignment rings

There are also structural guides.

Mingrui Ceramic parts are designed to deliver lifecycle stability and dimensional endurance in situations where failure is not acceptable. Mingrui Ceramic does not simply meet drawings. It works with its customers to develop material options and enhancements in manufacturability, creating operational value that goes beyond simple machining.

Global Competence in the Next Technology Era

The semiconductor industry is experiencing a new wave of innovation, powered by 3D chip stacking and hydrogen energy control, as well as defense-grade electronics.

Precision technical ceramics are the key enabler materials.

Mingrui Ceramics aims to expand its business beyond Asia by:

- multi-site support capabilities,

- Collaborations in engineering

- automation enhancement,

- Accelerating innovation cycles.

Major semiconductor producers are increasingly looking for suppliers that can provide reliability levels similar to those of European or U.S. manufacturers. Mingrui Ceramics is well positioned to meet this expectation because:

It maintains complete tracability records.

It understands compliance governance,

It uses manufacturing discipline linked to scientific measurement systems rather than mass-produced low-cost machining.

Mingrui Ceramic does not compete on price but on capabilities, reliability and global qualification.

Conclusion

Technical ceramics are shaping the performance, durability, and purity of next-generation manufacturing technologies as semiconductor technology advances. Mingrui Ceramic is one of few Asian manufacturers that can produce semiconductor-grade ceramics. It has unmatched machining expertise, advanced certifications and research-level partnership, as well as high-precision systems.

Companies looking to strengthen their supply chain resilience and performance can explore collaboration opportunities directly through the company’s official website:

https://www.mrceramicpart.com/

This article was originally published by IssueWire. Read the original article here.