(Isstories Editorial):- Shenzhen, Guangdong Jan 19, 2026 (Issuewire.com) – In a rapidly evolving global electronics and industrial manufacturing landscape, modular power supplies have moved from being supporting components to becoming an essential part of modern production and testing systems. As factories adopt higher levels of automation and product cycles shorten, stable and configurable power delivery is increasingly tied to production efficiency and product reliability. Within this context, Jetronl Instruments Co., Ltd. is gaining broader international recognition as a Top 10 Modular Power Supplier From China, reflecting its long-term focus on practical modular power solutions rather than short-lived technological trends.

Based in Shenzhen, Jetronl benefits from its proximity to one of the world’s most dynamic electronics manufacturing ecosystems. Over time, this environment has shaped the company’s approach to modular power design–prioritizing reliability, adaptability, and compatibility with real industrial workflows.

Modular Power as a Practical Response to Modern Manufacturing Needs

More on Isstories:

- Essential Guide For Electronics Factories: Advantages Of Partnering With China Leading DC Power Supplier Jetronl

- From Shenzhen to the World: Jetronl’s Strategic Growth as a Top 10 Modular Power Supplier From China

- China Leading DC Power Supply Manufacturer Jetronl Introduces Cutting-Edge Solution for High-End Electronic Manufacturer

- China Supplier Fasto’s Best Professional EPDM Rubber Washer For Solar Panel Installations

- Nicholas Tabor, MS, RMHCI Recognized by America’s Best in Medicine for Compassionate Mental Health Care

In many electronics factories today, production lines are no longer static. A single line may be required to support multiple product models, different voltage levels, or varying load conditions over its lifetime. Traditional fixed-output power supplies often struggle in such environments, as changes in production frequently require equipment replacement or significant reconfiguration.

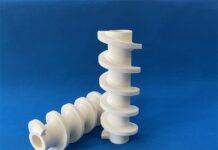

Modular power supplies offer a more practical alternative. By allowing power capacity and channel configuration to be adjusted through modular expansion, they enable manufacturers to adapt without disrupting existing infrastructure. This approach is especially valuable in industries such as automotive electronics, LCD manufacturing, communication devices, and new energy equipment, where testing requirements evolve quickly and downtime carries high costs.

Jetronl’s modular power systems are developed with these realities in mind. Rather than positioning them as standalone devices, the company designs its power solutions to function as part of larger testing and production systems, supporting continuous operation and gradual scaling as manufacturing needs change.

Building Modular Power Supply Expertise Through Long-Term Industry Collaboration

Founded in 1993, Jetronl Instruments has spent nearly three decades working closely with industrial users of electronic instrumentation. This long-term engagement has influenced how its modular power supplies are engineered. Instead of focusing purely on theoretical specifications, Jetronl places greater emphasis on output stability and precision during extended operation, predictable performance under varying loads, and convenient integration into automated test platforms.

The company’s background in instrumentation and system integration has also shaped its modular power architecture. In many applications–such as new energy vehicles, automotive electronics, opto-mechatronics equipment, automated testing and production lines, LCD panel aging tests, or communication equipment functional testing–power supplies must operate continuously for long periods while maintaining consistent voltage and current characteristics. Jetronl’s modular designs reflect this requirement, supporting stable operation in environments where reliability is more important than peak performance claims.

How Jetronl’s Modular Power Supplies Are Used in Real Applications

Across electronics manufacturing and industrial testing environments, Jetronl’s modular power supplies are most commonly deployed as part of structured and repeatable production workflows rather than as standalone devices. In LCD and display manufacturing facilities, for example, modular power systems are often integrated into large-scale aging and burn-in platforms. During these processes, hundreds of display modules must operate simultaneously under stable electrical conditions for extended periods. Jetronl’s modular architecture allows manufacturers to configure output capacity according to panel size and production volume, while maintaining consistent voltage and current levels throughout long test cycles.

In communication and navigation equipment factories, modular power supplies are frequently used in multi-channel functional testing stations. These environments require the simultaneous powering and verification of multiple devices, often with different voltage requirements. By using modular power systems, test engineers can adjust configurations as product models change, without redesigning the entire power infrastructure. This flexibility supports higher test throughput while preserving uniform test conditions across all channels.

Automotive electronics manufacturing presents another typical application scenario. Components such as control units, sensors, and auxiliary electronic modules must be tested under tightly controlled electrical parameters to ensure reliability in real vehicle environments. Jetronl’s modular power supplies support these workflows by providing stable and programmable power delivery that can simulate various field conditions encountered during vehicle operation. The ability to scale power capacity and isolate channels also helps manufacturers test multiple components in parallel without compromising accuracy.

In new energy and power electronics development, modular power systems are commonly used in laboratories and pilot production lines where engineers evaluate power conversion devices, control circuits, and electronic components related to battery assemblies. These test environments often evolve rapidly as designs are refined. Jetronl’s modular approach allows engineers to expand or reconfigure power capacity as testing requirements change, reducing the need for frequent equipment replacement and helping control development costs.

Beyond factory floors, modular power supplies are also applied in research institutions and university laboratories. In these settings, flexibility and repeatability are particularly important, as experimental setups may vary between projects. Modular power systems enable researchers to build adaptable test platforms while maintaining stable electrical performance, supporting both instructional use and applied research.

Across these diverse scenarios, the common requirement is not extreme specialization but dependable, scalable power delivery that integrates smoothly into existing systems. Jetronl’s modular power supplies address this need by emphasizing practical configuration, stable long-term operation, and compatibility with automated and laboratory environments–qualities that continue to drive their adoption across industries.

A Measured Approach to Supplier Growth and Market Positioning

Jetronl’s emergence as a Top 10 Modular Power Supplier From China is closely linked to its restrained and application-driven development strategy. Rather than positioning modular power as a one-size-fits-all solution, the company focuses on aligning its products with specific industrial workflows. This measured approach resonates with manufacturers who prioritize predictable performance and long-term support over aggressive feature expansion.

By combining modular power supplies with its broader experience in electronic instrumentation and system integration, Jetronl offers solutions that fit naturally into existing production environments. This compatibility reduces implementation risk and shortens the learning curve for engineering teams.

Looking Forward: Modular Power Supply Systems Supporting a Changing Industrial Landscape

As global manufacturing continues to move toward higher automation and smarter production systems, the role of modular power supplies is expected to grow. Their flexibility, scalability, and suitability for long-term operation make them well matched to the demands of modern electronics factories.

Jetronl’s continued focus on modular power development, grounded in real application experience and long-term industry engagement, positions the company to support this transition. From its base in Shenzhen to markets worldwide, Jetronl is steadily expanding its presence as a reliable modular power supplier for manufacturers seeking stable and adaptable power solutions.

For more information about Jetronl’s modular power supplies and industrial power solutions, please visit:https://www.jetronlinstrument.com/

Jetronl Instruments Co., Ltd.

[email protected]

Room 402, Yanda Technology Park, No. 116, Shuiku Road, Xixiang Street, Baoan District, Shenzhen

https://www.jetronlinstrument.com/

This article was originally published by IssueWire. Read the original article here.