(Isstories Editorial):- Taiyuan, Shanxi Jan 19, 2026 (Issuewire.com) – The global industrial manufacturing landscape is currently navigating a period of profound technological re-invention. As sectors from automotive to renewable energy demand components with higher precision, lower weight, and greater structural integrity, the role of specialized foundries has become more critical than ever. Standing at the forefront of this industrial shift is Taiyuan Simis Investment Casting Co., Ltd., a company that has solidified its reputation as a Global Leading Die Casting Service provider. By leveraging decades of metallurgical expertise and integrating it with modern CNC precision, Simis is redefining the benchmarks of high-scale casting production for the 2026 global market.

1. Industry Outlook 2026: The Convergence of Precision and Sustainability

As we move into the second half of the decade, the casting industry is being shaped by three transformative pillars. For a global leader like Taiyuan Simis, these trends represent both the challenge and the catalyst for growth:

More on Isstories:

- Pro-Line Trailers to Exhibit at MDA Car Show 2026

- COAST: The China Smart Glass Film Manufacturer Bridging Aesthetics and Energy Efficiency

- A Professional Guide to Choosing a High Quality Rare Earth Heat Blocking Window Film Manufacturer

- Scientist-Turned-Seeker Reframes Ancient Wisdom in Echoes from a Spiritual Name

- Empowering Green Buildings: China Smart Glass Film Manufacturer Providing Sustainable Privacy Solutions

The “Giga-Casting” Influence: Inspired by the electric vehicle (EV) revolution, there is a massive shift toward consolidating multiple small parts into single, large-scale die-cast components. This reduces assembly complexity and optimizes the resource allocation of manufacturers.

Material Science Innovation: The demand for high-strength aluminum and magnesium alloys is skyrocketing. Industries are seeking materials that provide superior thermal conductivity and fatigue resistance while maintaining a low weight-to-strength ratio.

Digital Foundry Transformation: The integration of AI-driven thermal simulation and real-time sensor monitoring in the casting process has moved from “optional” to “essential.” These technologies ensure that project budgetary efficiency is maximized by reducing scrap rates and ensuring first-time-right production.

2. Core Strengths: Why Taiyuan Simis Leads the Global Market

Established in 2004, but rooted in a collective history spanning over 40 years, Taiyuan Simis has built a production ecosystem that few can match. Their leadership in the Global Leading Die Casting Service sector is supported by several unique strategic advantages:

A. Geographic and Resource Advantage

Located in Taiyuan City, Shanxi Province, Simis operates in a region globally recognized for its abundance of iron ore and coal. This proximity to raw materials provides the company with an unshakeable supply chain foundation, ensuring that high-scale production remains insulated from global raw material volatility–a key factor for international partners managing long-term project value.

B. Multi-Process Versatility

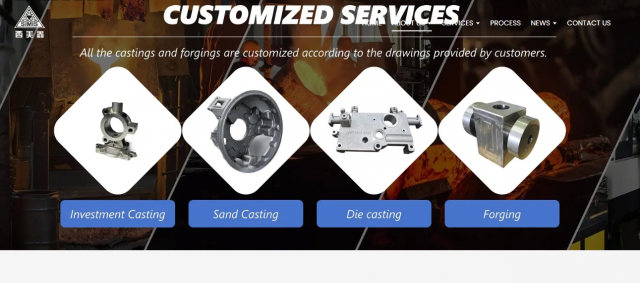

While many foundries specialize in a single method, Simis has mastered a spectrum of casting technologies:

Sophisticated Investment Casting: For complex geometries and superior surface finishes.

Detailed Die Casting: Ideal for high-volume, high-precision non-ferrous components.

Versatile Sand and Shell Mold Casting: Catering to large-scale industrial hardware and heavy machinery.

C. The Power of Integrated Facilities

With six specialized casting facilities and two advanced CNC machining workshops, Simis offers a “Single-Source” solution. This vertical integration allows for a seamless transition from liquid metal to a finished, precision-machined part, significantly reducing the operational lead times for international clients.

3. Product Application Scenarios: Powering Global Infrastructure

The versatility of Taiyuan Simis’s output means their components are the “silent engines” behind multiple critical industries.

I. Automotive and Aerospace: Light-weighting the Future

In the automotive sector, Simis’s die-casting expertise is used to produce engine blocks, transmission cases, and structural chassis components. For aerospace, where the allocation of specialized resources is paramount, their investment casting process provides the high-precision components required for flight-critical systems.

II. Energy and Chemical: Durability in Harsh Environments

The energy sector–including wind, solar, and traditional oil & gas–requires parts that can withstand extreme pressure and corrosion. Simis produces heavy-duty valves, pump housings, and turbine components that meet the strict durability specifications of the chemical industry, ensuring long-term asset protection for global energy providers.

III. Construction and Industrial Machinery

From hydraulic components to heavy-duty brackets used in high-rise construction, Simis provides the structural backbone for urban development. Their shell mold casting process is particularly effective for producing the high-durability parts needed for excavators and industrial cranes.

4. Strategic Value and Client Success Stories

Over the past four decades, the professionals at Simis have moved beyond the role of a traditional supplier, becoming Strategic Growth Partners for their clients. Their approach focuses on maximizing the commercial utility of every design.

Case Study: North American Automotive Tier-1 Supplier A major automotive supplier faced challenges with a complex transmission housing that suffered from porosity issues when cast by previous vendors. Simis’s engineering team utilized advanced thermal simulation to redesign the gating system. By optimizing the technical resource deployment, Simis reduced the defect rate by 15%, ensuring a more stable supply chain for the client’s high-volume assembly line.

Case Study: European Renewable Energy Project For a large-scale offshore wind farm project, the client required custom-designed corrosion-resistant housings. Simis leveraged its versatile sand casting capability to produce these oversized parts, integrating them with precision CNC machining to meet sub-millimeter tolerances. This comprehensive solution allowed the client to meet their installation deadlines while staying within their strategic project budget.

5. Commitment to Innovation and Human Capital

The “Simis Secret” lies in the continuous reinvestment into both technology and people. Their state-of-the-art facilities are equipped with the latest spectroscopy for material analysis and 3D coordinate measuring machines (CMM) for dimensional verification.

However, the company believes that technology is only as good as the hands that guide it. Their team of seasoned professionals is adept at handling the transition from a “detailed design” on a digital screen to a “large-scale production” on the foundry floor. This human-centric expertise ensures that every project, no matter how complex, results in top-quality outcomes that reflect the brand’s dedication to excellence.

6. Conclusion: Shaping the Industrial World

As a Global Leading Die Casting Service, Taiyuan Simis Investment Casting Co., Ltd. represents the bridge between traditional foundry wisdom and the future of precision manufacturing. In an era where the strategic efficiency of supply chains defines market success, Simis offers the reliability, scale, and technical depth required to drive global industrial progress.

Whether it is a standard part for a construction site or a custom-engineered component for a next-generation aerospace engine, Simis remains committed to its mission: Delivering quality without compromise and building the components that build the world.

For global B2B partners seeking to elevate their manufacturing capabilities with a partner that understands value, precision, and scale, the search ends at Simis.

To explore our comprehensive casting solutions or to discuss your upcoming custom project, please visit our official website.

Official Website: https://www.simis-manufacturer.com/

Taiyuan Simis Investment Casting Co., Ltd.

[email protected]

+86-17735177558

No 251, Changzhi Road, Taiyuan City, Shanxi Province, China

https://www.simis-manufacturer.com/

This article was originally published by IssueWire. Read the original article here.