(Isstories Editorial):- Xian, Shanxi Jan 19, 2026 (Issuewire.com) – How can modern infrastructure maintain structural integrity when exposed to decades of relentless weathering and thermal fluctuations? Is it possible for a component as small as a washer to dictate the lifespan of a multi-million-dollar solar installation or industrial building? In the global construction landscape, the answer lies in the precision of sealing technology.

As a China Top-Rated EPDM Rubber Washer Manufacturer, Fasto Industrial Co., Ltd. (Fasto) specializes in the engineering of high-performance sealing solutions designed to bridge the gap between mechanical fastening and environmental protection. An EPDM rubber washer is not merely a spacer; it is a sophisticated composite of Ethylene Propylene Diene Monomer, a synthetic elastomer celebrated for its extraordinary resistance to ozone, UV radiation, and extreme temperatures. By providing a flexible yet impenetrable barrier, these components ensure that moisture, dust, and corrosive agents cannot compromise the primary fastening point.

The Evolution of the Global Fastening Industry and Material Science

More on Isstories:

- Chinese Advanced Self-tapping Screws Solutions Provider Fasto: Enhancing Assembly Efficiency

- Fasto – China Top-Rated EPDM Rubber Washer Manufacturer: Ensuring Leak-Proof Sealing

- China Leading Custom Self-tapping Screws Factory Fasto At FASTENER POLAND

- Ningbo Mengting Outdoor Implement: China Top Headlamp Manufacture

- How The Pool Factory Is Transforming Backyards with Premium Above Ground Pools

With the rise of green building certifications and the expansion of renewable energy infrastructure, such as solar PV systems in coastal regions, the demand for longevity has never been higher. Standard galvanized steel or basic rubber components are no longer sufficient for environments characterized by high salinity or industrial pollutants. This shift has necessitated a move toward advanced polymers and multi-material composites.

Industry trends indicate a growing preference for “smart” fastening systems that can accommodate the thermal expansion and contraction of metal cladding and roofing. When metal sheets heat up under the sun, they move; without a high-quality sealing interface, this movement creates gaps that lead to leaks and structural fatigue. Consequently, the market has seen a surge in the adoption of bonded washers–where a metal backing is permanently fused to an elastomeric seal–to provide both structural distribution of load and a watertight fit.

China’s Strategic Role in the Global Supply Chain

In this evolving landscape, Chinese manufacturers have transitioned from high-volume producers to leaders in technical innovation and quality assurance. The “Made in China” label in the fastener industry now represents a sophisticated integration of raw material sourcing, automated precision manufacturing, and rigorous international compliance.

As a prominent EPDM rubber washer manufacturer, Fasto exemplifies this transition. By operating under IATF 16949 and ISO 9001 quality management systems, Chinese suppliers are now providing the engineering depth required for critical infrastructure projects in Europe, North America, and Australia. The ability to offer a centralized source for bimetal self-drilling screws, stainless steel bolts, and specialized EPDM rubber washer units allows global contractors to streamline their procurement while ensuring that every component in the fastening assembly meets the same high standard of durability.

Engineering the Perfect Seal: The Anatomy of Fasto EPDM Solutions

The effectiveness of a sealing system depends entirely on the physical properties of the elastomer. Fasto’s EPDM rubber washer products are engineered to maintain elasticity across a wide temperature spectrum, typically ranging from -40°C to 120°C. Unlike natural rubber, which can become brittle and crack when exposed to the sun’s ultraviolet rays, EPDM retains its molecular integrity, ensuring that the seal remains “live” for the duration of the building’s life cycle.

The importance of leak-proof sealing cannot be overstated. In metal roofing applications, a single failed washer can lead to water ingress that damages insulation, promotes mold growth, and eventually corrodes the underlying structural steel. To achieve the best leak-proof effect, Fasto utilizes a specialized vulcanization process that bonds the EPDM rubber washer to a metallic backing–often stainless steel or galvanized steel. This “bonded” design prevents the rubber from over-compressing or “squirting” out from under the screw head during installation, maintaining a uniform peripheral seal even under high torque.

Customization and Technical Precision

One of the core advantages of working with an experienced EPDM rubber washer manufacturer is the ability to customize dimensions and material densities for specific applications. Fasto offers a diverse portfolio, including:

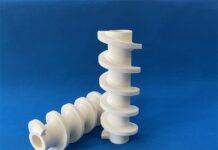

- Bonded Sealing Washers:Specifically designed for self-drilling screws, these feature a slightly concave metal backing that directs the sealing pressure inward toward the shank of the fastener.

- Flat and Mylar Washers:For electrical or specialized industrial applications where non-conductive properties or specific thickness tolerances are required.

- Custom Profiles:EPDM components can be tailored in terms of shore hardness (durometer) to match the fragility or rigidity of the mating materials, such as thin-gauge aluminum façades or heavy-duty steel rafters.

Quality is verified through continuous in-house testing. Metrics such as tensile strength, elongation at break, and compression set are routinely monitored. By adhering to international standards including DIN, ASTM, and AS/NZS, the EPDM rubber washer produced is guaranteed to perform in the most demanding environments, from high-load industrial floors to coastal roofing projects.

Real-World Reliability: Success Stories in the Field

The practical value of these components is best illustrated through their application in high-stakes environments. In a recent large-scale solar PV installation located in a high-salinity coastal region, the developer faced significant concerns regarding salt-air corrosion and water leakage at the mounting points. Fasto provided a comprehensive solution involving bimetal self-drilling screws paired with high-grade EPDM rubber washer units. The EPDM’s resistance to salt spray and UV ensured that the mounting holes remained hermetically sealed, preventing galvanic corrosion between the aluminum rails and the steel substructure.

Similarly, in a commercial warehouse project featuring an expansive metal roof, the use of Fasto’s bonded EPDM rubber washer allowed for rapid installation with a near-zero failure rate during pressure testing. The washers’ ability to compensate for the slight irregularities in the corrugated metal sheets provided the contractor with a reliable, repeatable sealing result that met stringent local building codes.

Excellence in Manufacturing and Global Support

Beyond the technical specifications of a single EPDM rubber washer, Fasto’s strength lies in its comprehensive manufacturing ecosystem. The company integrates the production of the fastener and the sealing component, ensuring perfect compatibility. This holistic approach eliminates the common industry problem where screws and washers from different sources do not seat correctly, leading to micro-leaks.

With production hubs designed for scalability, Fasto maintains a robust supply chain capable of supporting international project timelines. The integration of advanced coatings–such as Ruspert, dacromet, and mechanical galvanizing–ensures that the metal components of the assembly match the longevity of the EPDM rubber washer. This commitment to durability, backed by certifications like CE and ETA, positions the company as more than just a vendor; it is a technical partner for the global construction and energy industries.

By focusing on the synergy between material science and mechanical engineering, Fasto continues to set the benchmark for what a dedicated EPDM rubber washer manufacturer can achieve. In a world where infrastructure must withstand increasingly volatile climate conditions, the reliability of the seal is the ultimate safeguard for structural longevity.

For more information on high-performance sealing solutions and fastening systems, visit: https://www.fastoscrews.com/.

Fasto Industrial Co., Ltd.

[email protected]

+86-029-81165337

Room A-907, Greenland Center, NO.9 Jinye Road, Yan Ta District, Xi’an, China

https://www.fastoscrews.com/

This article was originally published by IssueWire. Read the original article here.