(Isstories Editorial):- Xian, Shanxi Jan 19, 2026 (Issuewire.com) – In the remote, sun-drenched plains of a utility-scale solar farm, thousands of photovoltaic panels stand as silent sentinels of the green energy transition. While the high-tech silicon cells capture the headlines, the long-term viability of these multi-million dollar investments often hinges on the smallest components. During a heavy summer rainstorm or under the relentless thermal expansion caused by peak afternoon heat, the integrity of every mounting point is tested.

It is within this demanding environment that the Best Professional EPDM Rubber Washer Supplier From China, Fasto Industrial Co., Ltd., provides the essential barrier between structural stability and environmental degradation. An EPDM rubber washer is more than a simple spacer; it is a precision-engineered seal designed to block moisture and cushion the contact between fasteners and mounting brackets. Utilizing high-grade EPDM, these washers provide exceptional UV and ozone resistance, maintaining a watertight, secure grip throughout the system’s 25-year lifespan.

Shifting Industry Standards in Renewable Energy

More on Isstories:

- China Leading DC Power Supply Manufacturer Jetronl Introduces Cutting-Edge Solution for High-End Electronic Manufacturer

- China Supplier Fasto’s Best Professional EPDM Rubber Washer For Solar Panel Installations

- Chinese Advanced Self-tapping Screws Solutions Provider Fasto: Enhancing Assembly Efficiency

- Fasto – China Top-Rated EPDM Rubber Washer Manufacturer: Ensuring Leak-Proof Sealing

- China Leading Custom Self-tapping Screws Factory Fasto At FASTENER POLAND

The global shift toward renewable energy has catalyzed a significant evolution in construction hardware requirements. As solar installations move into increasingly diverse geographical locations–from humid coastal regions to arid deserts–the industry has recognized that standard fastening components are often insufficient. The primary challenge in solar infrastructure is the management of thermal cycling. As temperatures rise and fall, the different materials in a solar mounting system expand and contract at varying rates. Without a high-quality EPDM rubber washer, this constant movement can lead to micro-gaps, loosening fasteners, and eventually, catastrophic leaks or structural fatigue. Consequently, there is a growing trend toward integrated sealing solutions where the washer is bonded to a metal backing, providing the structural rigidity of steel with the sealing compliance of rubber.

Mitigating Corrosion and Structural Fatigue

In the context of solar panel installations, the role of an EPDM rubber washer manufacturer has transitioned from a commodity supplier to a strategic technical partner. Reliability is the cornerstone of energy projects, where a single failed seal across ten thousand mounting points can lead to prohibitive maintenance costs and potential electrical grounding issues. The industry now demands components that can withstand “galvanic corrosion,” a process accelerated by moisture where dissimilar metals, such as aluminum rails and stainless steel screws, interact. By providing an effective insulating layer, a professional-grade EPDM rubber washer breaks the electrical circuit between these metals, significantly extending the life of the entire mounting assembly.

Technical Excellence: The Fasto Approach to Sealing Technology

Fasto Industrial Co., Ltd. has positioned itself at the forefront of this niche by refining the metallurgical and polymer standards required for such high-stakes applications. Their approach to manufacturing emphasizes the importance of the bonding process. In a bonded sealing washer, the EPDM element must be perfectly vulcanized to the metal backing–typically stainless steel or galvanized steel–to ensure they do not separate under the shear forces encountered during installation. This precision prevents the rubber from “mushrooming” or squeezing out from under the head of the screw, a common failure point in lower-quality alternatives. When a technician drives a fastener into a solar frame, the EPDM rubber washer must compress uniformly to create a concave seal that directs water away from the hole, a feature that Fasto has perfected through rigorous interface structure design.

Customization and Material Versatility

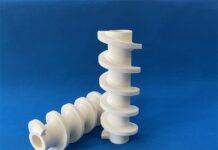

Beyond standard sealing, the necessity for customization in modern engineering cannot be overstated. Projects often require specific dimensions to accommodate oversized holes or unique load-bearing requirements. As a versatile EPDM rubber washer manufacturer, Fasto offers a spectrum of configurations, including flat metal washers, mylar flat washers, and round EPDM variants. Whether the application calls for a 1/4″ x 5/8″ bonded configuration for standard rail mounting or larger, thick-gauge washers for heavy-duty anchors, the focus remains on leak-proof sealing and long-term durability. This flexibility allows engineers to specify components that match the exact torque requirements and material thickness of their specific solar racking systems, eliminating the risks associated with “one-size-fits-all” hardware.

Quality Assurance and Environmental Resilience

The quality of the EPDM compound itself is where the true distinction lies. Inferior rubber products often contain high levels of fillers that degrade quickly when exposed to the intense UV light found on solar sites, leading to cracking and loss of elasticity within just a few years. Fasto’s proprietary EPDM formulations are engineered to maintain their physical properties across a temperature range of -40 degrees Celsius to over 120 degrees Celsius. This resilience ensures that the seal remains airtight even as the solar panels reach high operational temperatures during the day and cool rapidly at night. By minimizing issues such as hydrogen embrittlement in the accompanying fasteners and ensuring the washer maintains its “memory” or rebound capacity, the integrity of the solar installation is preserved against the elements.

Integrating Global Supply Chains for Project Success

Furthermore, the integration of these sealing components into a broader fastening strategy is essential for project success. Fasto’s expertise extends to Bimetal Self-Drilling Screws, which, when paired with a high-performance EPDM rubber washer, provide a comprehensive solution for attaching components to thick steel or aluminum substrates. This holistic view of the fastening system–considering how the screw, the coating, and the washer interact–reduces the risk of premature failure. With international certifications like CE and comprehensive testing reports from SGS, the technical transparency provided by the company gives global developers the confidence that their hardware will meet the stringent safety and longevity standards required by lenders and insurers in the energy sector.

As the scale of international solar projects continues to grow, the supply chain’s efficiency becomes as critical as the product’s quality. Maintaining production hubs that can service global demands ensures that project timelines are met without compromising on component precision. In an era where “sustainability” must apply to the hardware itself, the move toward long-lasting, corrosion-resistant sealing solutions is a logical progression. The humble EPDM rubber washer stands as a testament to the fact that in the world of advanced energy technology, the most significant protection often comes from the most fundamental components. By focusing on leak-proof performance and customizable durability, manufacturers are ensuring that the renewable energy infrastructure of today remains the reliable power source of tomorrow.

For more information on high-performance fastening and sealing solutions, visit: https://www.fastoscrews.com/.

Fasto Industrial Co., Ltd.

[email protected]

+86-029-81165337

Room A-907, Greenland Center, NO.9 Jinye Road, Yan Ta District, Xi’an, China

https://www.fastoscrews.com/

This article was originally published by IssueWire. Read the original article here.