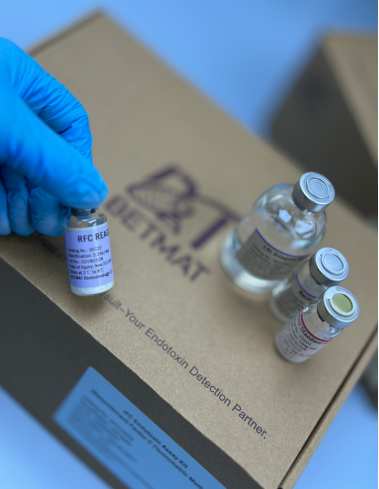

(Isstories Editorial):- Dover, Delaware Jan 19, 2026 (Issuewire.com) – The global pharmaceutical supply chain is currently confronting a dual imperative: ensuring uncompromised product sterility while meeting increasingly stringent Environmental, Social, and Governance (ESG) expectations. In response to this evolving landscape, BETMAT Biotechnology LLC has officially launched its High-Performance Sustainable Endotoxin Testing Services–a premium portfolio of diagnostic solutions purpose-built for next-generation quality control laboratories.

These services are centered on the strategic deployment of Recombinant Factor C (rFC) and Recombinant Cascade Reagent (rCR) technologies, offering a fully biosynthetic and animal-free alternative to conventional amebocyte lysate-based assays. Leveraging high-purity recombinant enzymes, the platform delivers a robust and regulatory-aligned solution for the Bacterial Endotoxins Test (BET) that operates independently of natural horseshoe crab resources.

Designed to meet the demands of modern pharmaceutical manufacturing, this specialized service provides quantitative, high-sensitivity endotoxin detection while effectively eliminating interference from (1,3)–D-glucans. As a result, Quality Control (QC) teams can achieve precise, reproducible contamination monitoring with enhanced analytical confidence.

More on Isstories:

- Explore The Ways to Navigate Business Ethics in the Modern Era

- Fasto – Professional Window Frame Screws Support From China Meeting IATF 16949 Standards

- China Top Verified Concrete Anchor Screws Supplier: Structural Reliability With ETA

- 15 Places to Visit in Sikkim in 2026

- Best-Selling Waterproof Headlamps in French Outdoor Stores 2025

I. The Global Evolution of Pyrogen Detection: Industry Trajectories and Technological FrontiersFrom Animal-Based Bioassays to Molecular-Level Precision

Pyrogen testing has undergone a profound methodological evolution, transitioning from the Rabbit Pyrogen Test (RPT) to highly sensitive, in vitro analytical platforms. The introduction of the Limulus Amebocyte Lysate (LAL) assay represented a pivotal advancement, enabling standardized and sensitive detection of bacterial endotoxins while significantly reducing reliance on live-animal testing. Today, the Bacterial Endotoxins Test (BET) is firmly established as a mandatory quality control (QC) requirement for parenteral pharmaceuticals and selected classes of medical devices.

As pharmaceutical modalities continue to increase in molecular and formulation complexity, the industry is progressively adopting kinetic analytical formats, including chromogenic and turbidimetric assays. These methods provide quantitative, time-resolved data with improved resistance to matrix interference, supporting advanced bioprocess control and risk-based quality assessment. This analytical evolution is particularly critical for Advanced Therapy Medicinal Products (ATMPs), where complex biological matrices demand absolute analytical specificity to prevent potentially life-threatening pyrogenic reactions in patients.

Regulatory Harmonization and the Pursuit of Global Safety Consistency

A defining feature of the contemporary pharmaceutical environment is the accelerating harmonization of compendial standards across major regulatory jurisdictions. The United States Pharmacopeia (USP), European Pharmacopoeia (Ph. Eur.), and Chinese Pharmacopoeia (ChP) have made substantial progress toward aligning their requirements for endotoxin testing methodologies. While this convergence facilitates global product registration and distribution, it simultaneously elevates expectations for method validation rigor.

Quality Assurance (QA) and Quality Control (QC) teams are now required to demonstrate that their endotoxin detection systems maintain accuracy, sensitivity, and robustness in the presence of complex excipient systems, novel delivery platforms, or inhibitory active pharmaceutical ingredients (APIs). Consequently, market demand has intensified for multi-pharmacopeia-compliant reagents and platforms capable of generating high-integrity data that withstand regulatory scrutiny across multiple regions, thereby streamlining submission pathways and reducing compliance risk.

Ecological Responsibility and the Emergence of Biosynthetic Testing Solutions

Sustainability has become an integral pillar of pharmaceutical manufacturing, driven by both regulatory expectations and corporate Environmental, Social, and Governance (ESG) commitments. The adoption of the 3Rs principle–Replacement, Reduction, and Refinement–has accelerated the search for alternatives to biologically sourced testing reagents. Traditional LAL reagents, dependent on a finite marine resource, present inherent ecological and supply chain vulnerabilities.

In this context, recombinant technologies, most notably Recombinant Factor C (rFC)-based assays, have emerged as scientifically robust and sustainable alternatives. These chemically defined, animal-free reagents offer superior batch-to-batch consistency, enhanced analytical specificity, and long-term supply stability. The transition toward biosynthetic endotoxin detection represents more than an environmental initiative; it reflects a strategic shift toward a more reproducible, resilient, and ethically responsible analytical framework for safeguarding pharmaceutical quality.

Integration of Process Analytical Technologies in Modern Biomanufacturing

Contemporary biomanufacturing increasingly embraces a Quality by Design (QbD) paradigm, in which product quality is proactively built into each stage of the production process rather than verified solely through end-product testing. As a result, demand for rapid, high-efficiency microbiological methods continues to rise, particularly in the manufacture of high-value biologics and cell-based therapies.

In-process endotoxin monitoring of raw materials, water systems, and intermediate purification streams enables early detection of microbial contamination, minimizing batch failure risk and protecting downstream operations. Automated kinetic endotoxin testing platforms, capable of delivering real-time or near-real-time analytical feedback, empower manufacturers to optimize process control, reduce release timelines, and ensure endotoxin levels remain consistently within validated safety thresholds at all critical control points.

II. BETMAT’s Strategic Advantages and Broad Analytical ApplicationsSpecialized Expertise in Advanced Microbiological Detection

BETMAT Biotechnology LLC is a specialized life science enterprise focused on the research, development, and global supply of high-performance endotoxin and pyrogen detection reagents. The organization is dedicated to addressing the most technically demanding challenges associated with the Bacterial Endotoxins Test (BET) by offering a comprehensive portfolio of rigorously validated analytical solutions.

Through deep expertise in the biochemical mechanisms of the endotoxin-triggered clotting cascade–and its modern recombinant analogues–BETMAT enables life science laboratories to achieve enhanced analytical precision and confidence. The company’s core competitive strength lies in delivering high-sensitivity, highly consistent reagents that simplify method validation for complex formulations, ensuring that Quality Control (QC) processes remain efficient, reproducible, and seamlessly integrated into pharmaceutical manufacturing workflows.

A Multidisciplinary Ecosystem of Diagnostic Solutions

BETMAT’s product portfolio is strategicaly designed to meet the diverse analytical requirements of the pharmaceutical, clinical, and biotechnology sectors. The offering includes:

Advanced LAL Assay Formats

Comprehensive solutions encompassing Gel-Clot, Kinetic Chromogenic, and Kinetic Turbidimetric methodologies, engineered to support a wide range of sample matrices and sensitivity specifications.

Synthetic Recombinant Assays

Fully animal-free Recombinant Factor C (rFC) and Recombinant Cascade Reagent (rCR) platforms, enabling customers to meet sustainability objectives while ensuring global pharmacopeial compliance.

Interference-Resistant Testing Kits

Specialized formulations developed for challenging matrices such as Fetal Bovine Serum (FBS) and high-concentration protein products, incorporating optimized buffers to neutralize inhibitory or enhancing substances.

Qualified Endotoxin-Free Consumables

A complete range of validated QC accessories–including endotoxin-free glassware, low-binding pipette tips, and LAL Reagent Water (LRW)–designed to eliminate exogenous contamination risk at every testing stage.

Together, these components form an integrated diagnostic ecosystem that supports robust, reproducible endotoxin testing across both routine and highly specialized applications.

Sector-Specific Applications and Patient-Centered Safety

BETMAT’s analytical solutions support critical safety requirements across multiple regulated sectors. Within pharmaceutical manufacturing, these reagents play a vital role in verifying depyrogenation efficiency, validating equipment cleanliness, and qualifying water systems. In clinical applications, endotoxin monitoring of dialysis fluids is essential to prevent pyrogenic reactions in patients undergoing long-term renal therapy.

Medical device manufacturers similarly rely on these detection systems to ensure that surgical instruments, implants, and invasive devices meet stringent USP and European Pharmacopoeia compliance requirements. By delivering accurate and reliable data in these high-risk environments, BETMAT helps bridge the gap between advanced analytical science and real-world patient protection.

Collaborative Partnerships for Global Regulatory Readiness

Beyond its role as a reagent provider, BETMAT operates as a technical and regulatory partner to bioprocessing, Quality Assurance (QA), and Quality Control teams. The adoption of next-generation methodologies–particularly recombinant endotoxin assays–requires comprehensive validation strategies and strong technical justification. BETMAT provides the specialized expertise and documentation support necessary to ensure successful method transitions.

This collaborative model is especially valuable for biotechnology and pharmaceutical companies pursuing global market authorization, where demonstrating method robustness and regulatory alignment is a critical success factor. By emphasizing efficient workflows, standardized data generation, and multi-pharmacopeial compliance, BETMAT supports its partners in maintaining operational excellence and achieving international regulatory acceptance.

III. Conclusion: Advancing Purity Through Innovation and Responsibility

As the biopharmaceutical industry advances toward increasingly complex modalities, including cell and gene therapies, the analytical technologies used to safeguard product safety must evolve in parallel. BETMAT Biotechnology LLC remains committed to the continuous advancement of endotoxin detection science, ensuring access to analytical solutions that combine exceptional performance with ecological responsibility.

By championing High-Performance Sustainable Endotoxin Testing Services, BETMAT supports a future in which pharmaceutical purity, regulatory confidence, and environmental stewardship are mutually reinforcing objectives. Through the delivery of interference-resistant, validated, and operationally efficient solutions, the organization helps ensure that life-saving therapies are manufactured to the highest standards of integrity–ultimately protecting patient health worldwide.

For comprehensive technical documentation, detailed product catalogs, and information on sustainable validation services, please visit the official website: https://www.betmatbio.com/

This article was originally published by IssueWire. Read the original article here.