(Isstories Editorial):- Wenzhou, Zhejiang Jan 16, 2026 (Issuewire.com) – As cities around the globe progress toward smart, electrified infrastructures, the need for durable, precise, and reliable electrical components is surging at an unprecedented pace. The crucial support for this transformation lies Sheet metal fabrication services for the Electrical Industry – essential services which ensure electrical systems remain safe, resilient systems capable of withstanding modern urban challenges – power distribution equipment enclosures smart-grid enclosures EV charging stations renewable energy installations all rely heavily on sheet metal fabrication services as critical backbone infrastructure components.

By integrating CNC precision machining, stamping, injection molding, cold heading forging and multi-material processing into one cohesive manufacturing ecosystem, LVMA stands out as an expert provider of complex yet consistent parts that meet technical and safety demands of today’s electrical industry. This press release explores why sheet metal fabrication is integral to urban development as well as how LVMA’s capabilities support future electrical infrastructure developments.

- An Essential Component of Safety, Protection, and Compliance Regulatory

Electrical systems installed in urban environments are subject to constant exposure to moisture, pollutants, vibration, heat and physical impact. Without strong protective enclosures and structural components made from precision-engineered sheet metal components, such systems would be highly vulnerable to failure and therefore highly at risk.

More on Isstories:

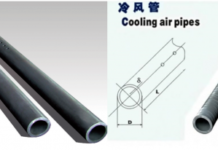

- Global Leading SiSiC/RBSIC Carbide Cold Air Tubes for Rapid Cooling – Thermal Shock Resistance

- Why Sheet Metal Fabrication Services Matter for the Electrical Industry in Today’s Urban Infrastructure

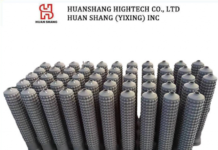

- Inside HUANSHANG’s SiSiC/RBSIC Roller Factory: Scaling Quality for Global Kiln Lines

- Global Leading SiSiC/RBSIC Grinding Buckets for Wholesale: Ultra-Wear Resistance for High-Abrasion Processing

- Industry Outlook for Die Casting Custom Metal Parts Manufacturing — Market Insights from FABTECH

Excellent sheet metal fabrication makes possible:

Enhance corrosion resistance for long-term outdoor use

Strength is needed to protect sensitive electrical assemblies.

Improvement in the heat dissipation performance of high-power electrical equipment

Comply with stringent electrical and fire safety standards

Electrical safety is of particular concern in densely populated areas where public health depends on it. Sheet metal products like distribution cabinets, control panels, junction boxes and switchgear housings help ensure essential electrical equipment operates securely and reliably.

- Advocating for Smart Cities and Digital Infrastructure

Urban environments are increasingly transitioning into data-driven ecosystems where electrical systems not only distribute power but also transmit information. Sheet metal fabrication provides precision housings that accommodate this change with precise tolerances to suit each application:

IoT-based power management systems

Remote monitoring and communication devices.

Sensor modules from Smart Building Automation Hardware.

As electrical systems continue to shrink in size and become more integrated, sheet metal fabrication provides the rapid development of tailored enclosures and mounting structures suitable for compact yet powerful electrical devices.

- Promoting Renewable Energy Development

Solar, wind and energy storage systems all rely heavily on sheet metal components for protecting their electronic systems and facilitating safe installation.

Example products of note are battery enclosure cabinets.

Structural supports for solar panels

Solar bracket

Weather-resistant outdoor power control boxes

These components must endure harsh environmental conditions over an extended period. Their precise fabrication helps ensure structural integrity, reduce maintenance requirements, and support sustainable and high-efficiency power generation.

- Fostering Urban Electrification and Electric Vehicle Infrastructure Development

Electric vehicles have become an essential element of urban infrastructure planning. Charging networks require numerous sheet metal structures such as:

Charging station housings and power electronics enclosures (P.E.I)

Cooling-system brackets, meters and control modules

Durable sheet metal ensures public charging stations remain protected against physical damage, weather conditions, and any attempts at tampering–an essential factor for driving widespread EV adoption.

Why Does the Electrical Industry Rely on High-Precision Fabrication?

Urban electrical systems today demand far more than simple structural support: They rely on accuracy, consistency and integration with advanced technologies for success. Sheet metal fabrication must meet this demand:

- Tight Dimensional Tolerances

- High repeatability for large-volume production

- Smooth edges and thorough surface treatments

- Complex geometries for multi-component assemblies.

- Compatibility with CNC machining, forging, welding and coating processes

Industries such as smart home electronics, industrial automation and power distribution require fabrication partners that understand the engineering specifications behind each part. That is where LVMA’s capabilities shine bright.

LVMA Provides Sheet Metal Solutions for Electrical Infrastructure

LVMA brings decades of production expertise and advanced manufacturing technology together to offer reliable, flexible and high-performance sheet metal fabrication services for global electrical manufacturers.

- Multi-Process Integration for Complex Parts

LVMA differs from traditional fabricators by consolidating multiple production processes into its manufacturing system, including:

CNC Precision Machining of sheet metal. Sheet Metal Stamping and Bending.

Integration ensures not only part accuracy but also more efficient workflows, faster delivery speeds, and reduced manufacturing costs.

- Expertise with Different Materials for Electrical Applications

LVMA works with materials commonly found in electrical systems:

Copper provides outstanding electrical conductivity, making it the material of choice for terminals and connectors.

Aluminum – light and corrosion-resistant housing and bracket material suitable for housings and brackets

Iron and steel provide high strength structural components.

Zinc alloys – durable and cost-effective functional parts

Engineering plastics – ideal for insulation and hybrid assemblies

Customers can utilize this flexibility to consolidate suppliers and streamline project management.

- Consistent Production for Mass-Volume Electrical Components

Electrical OEMs require stable and repeatable production quality. LVMA’s precision systems offer this assurance:

Dimensional consistency across large batches

Full-process inspection and measurement

Traceability from raw material through final shipment

Fast turnaround from prototype to mass production

Dependability is of utmost importance for electrical companies providing long-term infrastructure projects.

- High-Performing Components for Diverse Electrical Applications

LVMA provides sheet metal components for:

Cabinets for power distribution.

Breaker Mounting Back Plate

Terminal Block Mounting Plate

PLC Control Box Housing

Junction Box Sheet Metal Housing

Power Supply Metal Enclosure

Conclusion

Electrical infrastructure must remain reliable, efficient and adaptable in today’s rapidly developing urban environments in order to accommodate emerging technologies. Sheet metal fabrication plays an integral part in safeguarding electrical systems while supporting smart-city technologies, renewable installations and transportation electrification projects.

LVMA’s over 30 years of precision manufacturing experience enable it to provide advanced sheet metal solutions tailored specifically to meet the growing demands of the global electrical industry. Through integrated production capabilities, multi-material expertise and commitment to high-consistency quality standards, LVMA stands as an invaluable partner for companies developing urban electrical infrastructure.

For more information about LVMA’s sheet metal fabrication and precision component solutions, please visit: Www.lvma-cnc.com

This article was originally published by IssueWire. Read the original article here.