(Isstories Editorial):- Wuxi, Jiangsu Jan 16, 2026 (Issuewire.com) – As global kiln technology evolves toward higher efficiency, larger production capacity, and stricter quality control, silicon carbide rollers have become a core component in modern high-temperature kilns. In the middle of this transformation, the role of a wholesale SiSiC/RBSIC/silcon carbide roller factory is more critical than ever, ensuring stable supply, consistent quality, and scalable manufacturing for international kiln lines. HUANSHANG HIGHTECH CO., LTD, also operating under the name HUAN SHANG (YIXING) INC, opens a window into its specialized SiSiC/RBSIC roller manufacturing capabilities–demonstrating how advanced materials, industrial expertise, and global vision come together to support the future of kiln operations worldwide.

Silicon carbide rollers, especially those made from reaction bonded silicon carbide (RBSIC/SiSiC), are widely recognized for their high bending strength, excellent thermal shock resistance, low thermal expansion, and long service life under continuous high-temperature operation. These properties make them indispensable in roller kilns used for ceramic tiles, sanitary ware, lithium battery materials, and advanced technical ceramics. As firing temperatures rise and production cycles accelerate, the demand for reliable SiSiC rollers continues to grow across international markets.

Industry Outlook: Strong Momentum in High-Temperature Processing Markets

More on Isstories:

- Inside HUANSHANG’s SiSiC/RBSIC Roller Factory: Scaling Quality for Global Kiln Lines

- Global Leading SiSiC/RBSIC Grinding Buckets for Wholesale: Ultra-Wear Resistance for High-Abrasion Processing

- Industry Outlook for Die Casting Custom Metal Parts Manufacturing — Market Insights from FABTECH

- The Best Sheet Metal Bending Service for OEM Manufacturers — Boosting Quality and Lead Time

- Design Checklist for SiSiC Heat Exchanger Tubes: Wall Thickness, Joining – Thermal Cycling

The kiln furniture and heat-resistant materials industry is closely tied to the performance of downstream manufacturing sectors. In recent years, several structural trends have reshaped the global market and created long-term growth opportunities for silicon carbide rollers and related products.

First, the ceramic and tile industry is undergoing a significant upgrade. Large-format tiles, thin slabs, and high-speed roller kilns have become mainstream, particularly in Asia, the Middle East, and emerging markets. These production methods require rollers that can maintain straightness and mechanical strength over long spans and under repeated thermal cycling. Traditional materials struggle to meet these requirements, accelerating the replacement cycle toward SiSiC and oxide silicon carbide solutions.

Second, the rapid expansion of new energy industries is redefining kiln technology standards. Lithium battery materials, solar energy components, and magnetic materials all rely on precise thermal treatment to achieve consistent microstructure and performance. Roller kilns used in these applications often operate under controlled atmospheres and tight temperature tolerances, placing higher demands on roller stability, purity, and surface quality. Silicon carbide rollers, with their chemical inertness and resistance to oxidation, align well with these advanced requirements.

Third, environmental and economic pressures are driving manufacturers to improve energy efficiency and reduce downtime. Longer-lasting kiln rollers mean fewer shutdowns, lower maintenance costs, and reduced material waste. Lightweight yet strong SiSiC rollers also contribute to lower kiln thermal mass, improving heating and cooling efficiency. As sustainability becomes a key decision factor, kiln furniture with extended service life and stable performance gains a clear competitive advantage.

In addition, globalization of kiln equipment supply chains is reshaping purchasing behavior. Kiln builders and end users increasingly seek long-term partners capable of providing standardized quality at scale, along with customization and technical support. This trend favors manufacturers with integrated production systems, strong quality management, and experience serving international markets.

Looking ahead, the industry is expected to continue moving toward intelligent kilns, automation, and digital control systems. These developments will further increase the need for dimensionally precise, mechanically consistent silicon carbide rollers that can integrate seamlessly into high-speed, high-load kiln lines.

HUANSHANG HIGHTECH: Scaling Quality from Factory Floor to Global Markets

Founded in 2005, HUANSHANG HIGHTECH CO., LTD is a foreign-invested enterprise with a strong foundation in high-temperature materials manufacturing. Under the corporate structure of HUANSHANG HIGHTECH and HUAN SHANG (YIXING) INC, the company operates three family-owned factories, each specializing in different product categories. This structure allows HUANSHANG to combine focused expertise with group-level coordination and investment strength.

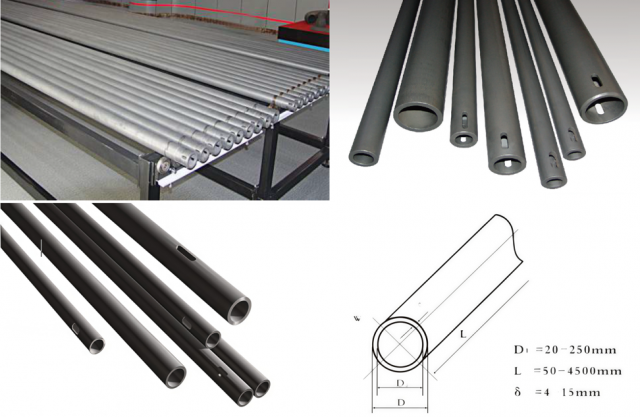

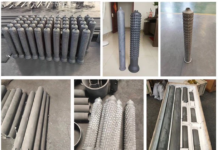

One of HUANSHANG’s key factories is dedicated to the production of sintered silicon carbide products, with a particular emphasis on RBSIC/SiSiC and oxide silicon carbide kiln furniture. Within this facility, SiSiC/RBSIC rollers are manufactured using carefully controlled processes, from raw material selection and forming to high-temperature reaction bonding and final inspection. The result is a product line designed to meet the rigorous demands of continuous industrial kiln operation.

HUANSHANG’s silicon carbide rollers are widely used in roller kilns for ceramic tiles, sanitary ware, bricks and tiles, microcrystalline stone, foam ceramic insulation materials, powder metallurgy components, lithium battery materials, solar energy products, magnetic materials, abrasive tools, and precision casting. Their consistent diameter, straightness, and surface finish help ensure smooth material transport, uniform firing, and reduced breakage rates.

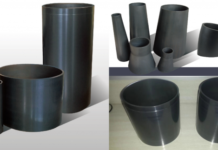

A key advantage of HUANSHANG lies in its comprehensive product range. In addition to rollers, the company supplies beams, battens, plates, setters, and other kiln furniture components in various specifications. This enables customers to source complete kiln furniture solutions from a single supplier, simplifying procurement and ensuring compatibility across the kiln system.

HUANSHANG has built long-term partnerships with kiln manufacturers and end users in both domestic and international markets. In ceramic tile production lines, customers report improved kiln stability and reduced roller replacement frequency after switching to HUANSHANG SiSiC rollers. In lithium battery material processing, the company’s rollers support consistent high-temperature sintering while maintaining dimensional accuracy over extended production cycles.

Beyond manufacturing, HUANSHANG HIGHTECH is also a group company that has invested in and acquired additional factories over the years. This strategic expansion strengthens its supply chain resilience, broadens its technical capabilities, and positions the company as one of the industry players with the most complete ranges of kiln furniture and heat-resistant materials.

A Long-Term Partner for the Future of Kiln Technology

HUANSHANG’s approach is not limited to supplying products; it focuses on building long-term value for customers. By combining application knowledge, production scale, and strict quality control, the company supports clients in optimizing kiln performance, reducing operational costs, and adapting to evolving market requirements.

As high-temperature industries continue to advance toward higher efficiency, sustainability, and precision, HUANSHANG HIGHTECH CO., LTD remains committed to delivering reliable silicon carbide solutions that meet global standards. Its SiSiC/RBSIC roller factory stands as a practical example of how quality can be scaled without compromise–supporting kiln lines around the world.

For more information about HUANSHANG’s SiSiC/RBSIC rollers and complete kiln furniture solutions, please visit https://www.hshightec.com/.

This article was originally published by IssueWire. Read the original article here.