(Isstories Editorial):- Wenzhou, Zhejiang Jan 16, 2026 (Issuewire.com) – As competition in global manufacturing increases, selecting an effective CNC machining partner is of vital importance in terms of production efficiency, cost control and long-term product quality. Companies searching for high-volume production require partners with strong technical abilities that can scale production as needed, manage complex processes efficiently and ensure consistent precision throughout. With more industries such as automotive, electronics and smart home products embracing large batch customization and rapid delivery expectations than ever before, reliable CNC milling suppliers become even more essential than before.

To assist procurement teams and project engineers in making informed decisions, this guide outlines four essential steps for selecting LVMA as their CNC milling partner for high-volume manufacturing of electrical components, automotive systems, furniture hardware, and industrial equipment.

Step One: Assess Technical Capabilities and Equipment Scalability

More on Isstories:

- How to Find the Best CNC Milling Partner for High-Volume Manufacturing

- Lime Media Group Appoints New Leadership to Support Next Phase of Growth

- Buyer Guide — Selecting a Custom CNC Turning Partner for Complex Metal Parts

- Future Leading SiSiC/RBSIC Cantilever Paddles: Lightweight Strength for Continuous Kilns

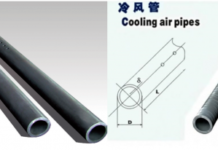

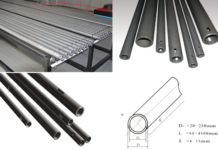

- Global Leading SiSiC/RBSIC Carbide Cold Air Tubes for Rapid Cooling – Thermal Shock Resistance

As part of your selection process for a CNC milling partner, the initial step should be assessing whether they have both the technical foundation and production resources to support large-volume production. Throughput should not come at the expense of precision in industries where tolerance errors of just microns can cause assembly failures, safety concerns or costly redesigns.

An effective CNC milling partner should demonstrate:

Modern factory equipped with multi-axis CNC milling machines

Integration capabilities include turning, drilling, tapping and high-speed milling.

Experience with complex geometries and tight tolerances

Skilled at transitioning between prototype, small batch production and mass production efficiently

LVMA stands out in this arena due to its vertically integrated production ecosystem. Boasting over three decades of machining expertise and housing dozens of core processes in one system, LVMA’s integrated approach allows it to seamlessly run CNC milling operations alongside injection molding, forging, and stamping lines for short lead times and reliable quality manufacturing with high volume production lines. Their technical accumulation also facilitates processing diverse materials like lightweight aluminum to heavy-duty steel with consistent accuracy and surface finishes ensuring long-term high volume manufacturing operations.

Step Two: Examine Certifications, Quality Systems and Compliance Standards

An international CNC milling partner should adhere to international quality systems and certifications that directly influence defect rates, production traceability, environmental responsibility, and long-term reliability.

Check for certifications such as:

ISO 9001 – Standardizes Quality Management Practices

IATF 16949 – Used in automotive-grade parts production environments.

RoHS reports ensures compliance with environmental and hazardous substance restrictions

LVMA holds ISO 9001, IATF 16949 and RoHS certifications to demonstrate its commitment to global quality benchmarks and responsible manufacturing practices. Furthermore, these credentials ensure that every stage–from material inspection through manufacturing process measurement and final packaging–is thoroughly controlled and documented.

Find a CNC milling partner who actively takes part in global industry exhibitions is an indicator of credibility and innovation, such as LVMA’s participation at Asia’s Industrial Automation Show (IAS). IAS attracts leading companies in robotics, intelligent manufacturing, digital production, component engineering and component assembly industries; while its participation by LVMA highlights our dedication to keeping up with cutting-edge machining technologies, automation applications, global industry standards as well as high volume customers’ quality requirements resulting in greater production efficiency and production outputs.

Step 3: Assess Production Flexibility, Delivery Speed and Project Management Strength

High-volume manufacturing often includes fluctuating production schedules, multiple product variations, and tight delivery deadlines; therefore, an ideal CNC milling partner must exhibit these traits.

Flexible scheduling and capacity expansion capabilities.

Agile manufacturing workflows

Professional supply-chain coordination

Fast sample verification and secure mass production cycles

LVMA excels in agile delivery thanks to its fully integrated supply chain and in-house multiprocess system. Instead of outsourcing key processes, LVMA directs upstream and downstream links themselves ensuring predictable lead times even for complex orders. Their standard project management system supports simultaneous sample development, tooling preparation, engineering adjustments, quality audits allowing customers to accelerate product launches while keeping consistent supplies uninterrupted.

Automotive and electrical system industries requiring large volumes of identically specced parts often rely on LVMA’s consistent manufacturing process and reliability as their long-term partner.

Step 4: Examine Your Partner’s Core Strengths, Case Studies and Industry Applications

Selecting an ideal CNC milling partner requires carefully considering their real-world performance. A reliable supplier must be capable of providing:

Proven application cases across various industries.

Long-term partnerships and solid customer references.

Demonstrated expertise in handling high-complexity orders that demand consistent quality performance.

Global Supply programs need scalable production capacities in order to remain successful.

LVMA boasts several competitive advantages, including:

- Integrating Multiple Processes Under One System

CNC machining can be combined with injection molding, cold heading forging, stamping and surface treatment to provide one-stop production of precision components.

- Materials Versatility

From copper and iron, aluminum, zinc, and plastics LVMA is proud to support diverse material categories for components used in different areas such as:

Electrical assemblies, automotive mechanisms, furniture hardware, appliance components and industrial machinery require specific expertise for proper functioning. 3. High-Complexity Product Knowledge

LVMA excels at producing parts with complex geometries, complex multi-step machining needs and tight tolerances that must remain consistent across mass production runs.

- Global Customer Success Cases

LVMA has supplied millions of precision components to clients in Europe, North America, and Asia – for applications including:

Automobile connectors and structural parts

Electrical terminal blocks and housings

High strength forged hardware.

Functional components made from injection-molded components

These capabilities, coupled with our global certifications, scalable production capacity and extensive milling expertise make LVMA the top choice among businesses seeking out CNC milling for high-volume manufacturing applications.

Finding an appropriate CNC milling partner for high-volume manufacturing requires thorough assessment of technical capabilities, certifications, delivery agility and industry performance. LVMA stands out by fulfilling all four criteria and offering integrated, high-precision, globally certified manufacturing solutions with long-term stability and superior product consistency.

For more information about LVMA’s CNC milling solutions and full-process manufacturing services, please visit: https://lvma-cnc.com/

This article was originally published by IssueWire. Read the original article here.