(Isstories Editorial):- Wuxi, Jiangsu Jan 16, 2026 (Issuewire.com) – As high-temperature industrial processes continue to evolve toward higher throughput, tighter quality control, and faster thermal cycling, advanced cooling components are becoming essential to kiln and furnace performance. In the middle of this evolution, Global Leading SiSiC/RBSIC/silcon carbide Cold air tube products are gaining recognition as a reliable solution for rapid cooling and exceptional thermal shock resistance. HUANSHANG HIGHTECH CO., LTD–also operating under the name HUAN SHANG (YIXING) INC–leverages its long-standing expertise in silicon carbide materials to deliver cold air tubes engineered for extreme temperature differentials and continuous industrial operation.

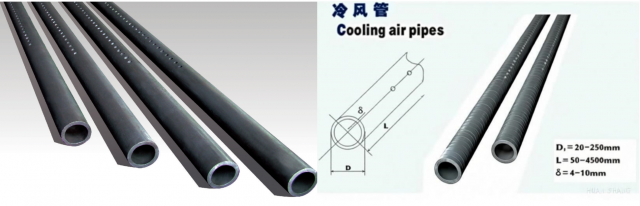

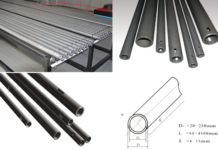

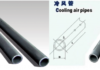

SiSiC (reaction bonded silicon carbide, RBSIC) cold air tubes are designed to introduce cooling air into high-temperature zones without compromising structural integrity or system stability. Compared with metallic or conventional ceramic alternatives, silicon carbide cold air tubes offer superior thermal shock resistance, high mechanical strength at elevated temperatures, excellent oxidation and corrosion resistance, and long service life. These properties make them especially suitable for kilns and furnaces where rapid cooling, frequent temperature fluctuations, and harsh atmospheres are unavoidable.

Industry Outlook: Fast Thermal Cycling and Process Efficiency Shape Demand

More on Isstories:

- Global Leading SiSiC/RBSIC Carbide Cold Air Tubes for Rapid Cooling – Thermal Shock Resistance

- Why Sheet Metal Fabrication Services Matter for the Electrical Industry in Today’s Urban Infrastructure

- Inside HUANSHANG’s SiSiC/RBSIC Roller Factory: Scaling Quality for Global Kiln Lines

- Global Leading SiSiC/RBSIC Grinding Buckets for Wholesale: Ultra-Wear Resistance for High-Abrasion Processing

- Industry Outlook for Die Casting Custom Metal Parts Manufacturing — Market Insights from FABTECH

The global market for kiln furniture and heat-resistant components is being reshaped by several long-term industry trends. Among them, the need for faster cooling cycles and higher process efficiency stands out as a key driver for cold air tube applications.

In the ceramic, brick, and tile industries, manufacturers are increasingly adopting fast-firing kilns to boost productivity and reduce energy consumption per unit. These kilns rely on precise control of both heating and cooling zones. Rapid cooling is critical for controlling microstructure, preventing deformation, and achieving consistent product quality. Cold air tubes must withstand repeated exposure to extreme temperature gradients, making material selection a decisive factor. Silicon carbide’s low thermal expansion and high thermal shock resistance provide a clear advantage in this context.

The rise of advanced materials manufacturing further amplifies this demand. Industries such as lithium battery materials, solar energy components, magnetic materials, and powder metallurgy require tightly controlled thermal profiles, including rapid cooling stages that influence material properties. As production lines become more automated and continuous, cooling components must deliver stable performance over long operating cycles with minimal maintenance.

Energy efficiency and sustainability considerations also play an important role. Faster and more controlled cooling can reduce overall kiln residence time and energy consumption. Lightweight yet strong silicon carbide components contribute to lower thermal mass, allowing systems to respond more quickly to process adjustments. As environmental regulations tighten and energy costs rise, manufacturers are investing in kiln upgrades that incorporate high-performance cooling solutions.

From a global sourcing perspective, kiln builders and end users increasingly seek suppliers capable of delivering consistent quality at scale. Cold air tubes must meet strict dimensional tolerances to integrate seamlessly into kiln structures, while also offering predictable thermal and mechanical behavior. This trend favors experienced manufacturers with integrated production capabilities and a deep understanding of high-temperature applications.

Looking ahead, the demand for SiSiC/RBSIC cold air tubes is expected to grow steadily as industries continue to prioritize fast thermal cycling, high productivity, and reliable operation under extreme conditions. Advanced ceramic materials will remain central to meeting these evolving requirements.

HUANSHANG HIGHTECH: Expertise in SiSiC Cold Air Tube Solutions

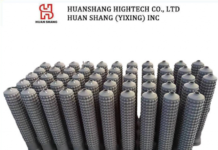

Founded in 2005, HUANSHANG HIGHTECH CO., LTD is a foreign-invested enterprise specializing in high-temperature and heat-resistant materials. Operating under the names HUANSHANG HIGHTECH CO., LTD and HUAN SHANG (YIXING) INC, the company manages three family-owned factories, each dedicated to different product categories. This structure enables focused manufacturing expertise while maintaining group-level integration and investment strength.

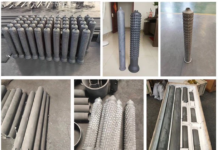

One of HUANSHANG’s core factories is dedicated to the manufacturing of sintered silicon carbide products, including reaction bonded silicon carbide (RBSIC/SiSiC) and oxide silicon carbide kiln furniture. Building on this foundation, the company produces SiSiC/RBSIC cold air tubes designed to perform reliably under severe thermal shock and rapid cooling conditions.

HUANSHANG’s silicon carbide cold air tubes are engineered with dense microstructures that provide excellent resistance to cracking and deformation during sudden temperature changes. Their high mechanical strength at elevated temperatures ensures structural stability, even when exposed to high-velocity cooling air in hot kiln zones. In addition, silicon carbide’s chemical inertness helps protect the tubes from oxidation and corrosion in aggressive kiln atmospheres.

The application scope of HUANSHANG’s cold air tubes spans a wide range of industries, including ceramics, bricks and tiles, microcrystalline stone, foam ceramic insulation materials, powder metallurgy, lithium battery manufacturing, solar energy, magnetic materials, abrasive tools, geological prospecting and analysis, precision casting, food processing, and the steel industry. In these sectors, cold air tubes play a crucial role in managing cooling rates and maintaining product quality.

Customer projects include high-speed ceramic tile kilns where HUANSHANG SiSiC cold air tubes support uniform and controlled cooling, reducing product defects and improving yield. In lithium battery material production, the tubes enable precise thermal transitions that influence particle structure and performance. Steel and metallurgical customers benefit from improved equipment reliability and reduced downtime due to the tubes’ long service life.

A key competitive advantage of HUANSHANG HIGHTECH is its comprehensive product portfolio. In addition to cold air tubes, the company supplies silicon carbide beams, rollers, radiant tubes, heat exchanger tubes, plates, battens, setters, and other customized kiln furniture components. As a group company that has also invested in and acquired additional factories, HUANSHANG is recognized as one of the industry players with a relatively complete range of kiln furniture and heat-resistant material specifications.

Commitment to Reliability in Extreme Thermal Environments

HUANSHANG HIGHTECH places strong emphasis on quality control and process stability. From raw material preparation and forming to reaction bonding, machining, and final inspection, every stage of production is managed under strict internal standards. Continuous investment in equipment and process optimization ensures consistent product performance across different specifications and production batches.

By combining material science expertise with extensive application experience, HUANSHANG supports customers in selecting and integrating cold air tube solutions that match their specific kiln designs and operating conditions. This collaborative approach helps customers achieve faster cooling, improved product quality, and lower operating costs.

As high-temperature industries continue to demand rapid cooling, higher efficiency, and greater resistance to thermal shock, SiSiC/RBSIC cold air tubes will remain an essential component of modern kiln systems. HUANSHANG HIGHTECH CO., LTD is committed to advancing silicon carbide solutions that meet these challenges and support sustainable industrial progress.

For more information about HUANSHANG’s SiSiC/RBSIC cold air tubes and comprehensive heat-resistant material solutions, please visit https://www.hshightec.com/.

This article was originally published by IssueWire. Read the original article here.