(Isstories Editorial):- Dongguan, Guangdong Sheng Jan 15, 2026 (Issuewire.com) – In the contemporary printing and packaging landscape, the surface finish of paper and board is a critical determinant of both product aesthetics and functional durability. From protective coatings on food packaging to high-gloss finishes on luxury consumer goods, the quality and consistency of the coating application are non-negotiable for brand integrity and shelf life. The demand for faster turnaround times, coupled with a growing necessity for eco-friendly, water-based varnishes and specialized functional coatings, requires finishing machinery that operates at unprecedented speeds with micron-level precision. This technological imperative is driving the development of highly automated coating systems that can integrate seamlessly into high-volume production lines. The industry seeks solutions that minimize waste, maximize throughput, and offer versatility across a range of coating formulations and paper stocks.

Through focused research and development, Sunkia Machinery is delivering Advanced Automatic High-Speed Paper Coating Solutions that incorporate highly reliable and precise application systems designed to transform bulk paper stock into high-value finished products, offering superior protective and decorative surface treatment for paper and board materials.

The Strategic Role of Coating in Modern Print Finishing

More on Isstories:

- Immigrant Entrepreneurship in America by Gorm Tuxen Achieves #1 Amazon Bestseller Status

- Colle AI Formalizes Strategy Around Cross-Chain Asset Versioning Infrastructure.

- Imagen Network Sets Forth Multi-Perspective Rendering Initiative for Immersive Asset Creation

- Apolosign Digital Wall Calendar Tackles “Proxy Parenting” in U.S. Homes

- 25 Countries for Solo Travelers to Discover Themselves

The transition of post-press finishing from a secondary process to a high-value strategic component is reshaping capital equipment demands. Efficiency, environmental compliance, and adaptability are the new benchmarks.

Industry Trends: Speed, Versatility, and Sustainability

The market is currently experiencing significant trends that challenge conventional paper coating technology:

- Shift to High-Speed Production:As printing presses become faster, the finishing line must keep pace. Automatic high-speed coating machines must offer operational stability at high volumes without compromising coating uniformity, which is a significant engineering challenge, particularly with large format substrates.

- Environmental Compliance and Functionality:There is a pronounced industry pivot toward water-based, UV, and LED-curable coatings. These formulations reduce or eliminate Volatile Organic Compounds (VOCs), aligning with global sustainability mandates. Furthermore, coatings are increasingly functional, providing enhanced abrasion resistance, moisture barriers, or specialized soft-touch effects, requiring machinery capable of handling various viscosities and curing mechanisms.

- Digital Integration:The rise of digital print demands finishing equipment that can handle short runs and variable data with quick changeover times, necessitating highly automated control systems for rapid preparation and cleanup.

These demands mean that modern coating equipment must be fundamentally versatile. Automatic High-Speed Paper Coating systems are expected to manage different types of varnishes, from aqueous protective layers to high-solid decorative finishes, all while maintaining stringent quality standards.

Sunkia Machinery‘s Commitment to Innovation

Since its establishment in 2008, Sunkia Machinery has been insisting on the principles of “Quality, Credibility, and Passion”. For the last 15 years, the company has driven many major innovations and has successfully become China’s leading brand in its field. The company is a leader in its field and is dedicated to producing paper coating technology and the highest quality equipment. Its core focus is on R&D and manufacturing of Multifunctional Paper Varnishing and Paper Coating Machine systems, which are supplied to many printing group companies and public companies. This history of specialized development is the foundation of its automatic high-speed paper coating solutions.

Unpacking the Advantages of automatic high-speed paper coating solutionssss

The competitive advantage of advanced paper coating technology stems from engineering solutions that solve operational pain points while delivering superior product quality.

Precision and Automation in Application

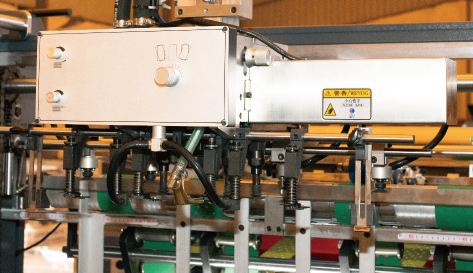

A core strength of advanced automatic high-speed paper coating solutions is their ability to control the coating film weight with extreme accuracy. Automated systems use advanced metering mechanisms–often precision anilox or rubber roller setups–to ensure the varnish layer is applied uniformly, typically within a few microns of the target thickness. This precision is critical for:

Cost Management: Minimizing material consumption by avoiding excessive coating application.

Quality Consistency: Ensuring the same level of gloss or protection across millions of units, which is vital for brand uniformity.

Defect Reduction: Preventing issues like “orange peel” texture or uneven coverage that are exacerbated at high speeds on less precise machinery.

The automation built into these systems extends beyond the coating head itself, encompassing automated feed, delivery, quick wash-up cycles, and fault detection, all contributing to maximum machine uptime and reduced operator dependency.

Operational Versatility and Application Scenarios

The multi-functionality of these paper coating and varnishing machines allows printing houses to serve diverse high-value market segments:

Premium Packaging (Scenario): Consider a company producing high-end liquor packaging. The final carton requires a specific soft-touch coating for a tactile premium feel, followed by UV spot coating for logo emphasis. An automatic high-speed paper coating solutions must first apply the full-coverage soft-touch varnish smoothly at 15,000 sheets per hour. Then, the system must maintain the necessary stability to prepare the surface for the subsequent, highly accurate spot UV varnish application. The machine’s precise metering capability ensures the exact desired texture is achieved and maintained across the entire production run.

Functional Coating for Food Safety (Scenario): A supplier of frozen food cartons requires a water-based, grease-resistant barrier coating. The coating machine must reliably apply this functional layer at speed, followed by rapid drying to prevent moisture absorption into the paperboard, which would compromise the carton’s structural integrity. The equipment’s high-speed, controlled drying system is the difference between a compliant, structurally sound carton and one that fails in cold storage conditions.

Commercial Printing: In the book publishing industry, where vast quantities of book covers and catalogs are produced, the use of UV or aqueous varnish is essential for scuff resistance and durability. The speed and reliability of the coating system allow commercial printers to meet tight publishing deadlines while delivering a finished product that stands up to heavy consumer handling.

The versatility offered by the Multifunctional Paper Varnishing and Paper Coating Machine means that the investment supports numerous revenue streams, from protective layers on packaging to high-decorative finishes on advertising materials.

Reshaping the Future of Print Finishing

The continued refinement of advanced automatic high-speed paper coating solutions is directly contributing to the evolution of the print and packaging industries. By enabling faster processing of complex, eco-friendly coatings, the technology helps clients reduce their environmental footprint and shorten their time-to-market.

The dedication to producing the highest quality equipment and the foundational principles of Quality, Credibility, and Passion are the drivers behind Sunkia Machinery’s success. As the industry continues its push toward fully integrated and automated production lines, the role of specialized coating technology that offers both high-speed performance and precise multi-functionality will only become more prominent. Choosing a solution provider with a history of major innovation and a clear focus on the highest quality equipment ensures that printing group companies and public companies are equipped to meet the future demands of product presentation and durability.

For further information on automatic high-speed paper coating and varnishing solutions, visit: https://www.sunkiamachinery.com.

Guangdong Sunkia Machinery Technology Co., Ltd.

[email protected]

+86 0769 82782808

745# Shida Road, Dalingshan Town, Donguan Cicty, Guangdong Province, China

https://www.sunkiamachinery.com

This article was originally published by IssueWire. Read the original article here.