(Isstories Editorial):- Danyang, Jiangsu Jan 13, 2026 (Issuewire.com) – The modern digital landscape has fundamentally altered human visual habits. With the average individual spending upward of seven hours a day engaging with digital screens, the physiological impact of high-energy visible (HEV) blue light has become a central concern for the optical industry. Blue cut lenses, designed to selectively filter out harmful wavelengths between 400nm and 450nm while allowing beneficial turquoise light to pass, have transitioned from a niche specialty item to a fundamental requirement for global consumers.

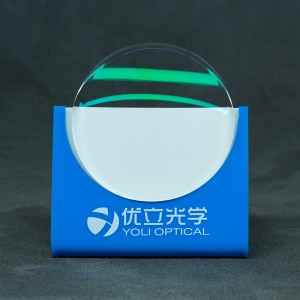

In this competitive market, identifying a China Best Blue Cut Lens Supplier requires looking beyond mere production volume to find a partner that integrates advanced polymer chemistry with rigorous manufacturing standards. Jiangsu Youli Optics Spectacles Co., Ltd. (YOLI) has emerged as a pivotal figure in this sector, bridging the gap between high-capacity industrial output and the precision engineering required for modern ophthalmic solutions.

The Evolution of the Global Optical Market and Blue Light Protection

More on Isstories:

- What Makes China Blue Cut Lens Supplier YOLI The Best Choice For Global Distributors?

- China Leading Photochromic Lens Manufacturer YOLI: Post-Event Insights From SIOF

- LAX Strengthens Network Infrastructure to Improve Accessibility and Transaction Efficiency

- Mohamed Al Zaabi: Steering Royal Yachts Toward Maritime Excellence

- Get Featured in Our Online PR Magazine at 15% Discount at IssueWire

The global optical lens market is currently undergoing a significant transformation driven by aging populations in developed nations and increasing digital penetration in emerging economies. Statistics suggest that the demand for functional lenses–those offering more than simple vision correction–is outstripping the growth of standard clear lenses. Within this context, blue-blocking technology has seen the highest CAGR (Compound Annual Growth Rate) among lens coatings and treatments.

Industry trends indicate that distributors are no longer just looking for a product; they are seeking supply chain stability and technological reliability. As blue light awareness grows, consumers are becoming more discerning about “color cast” and “residual reflection,” two common technical hurdles in blue cut lens production. Suppliers who can minimize the yellow tint associated with traditional blue blockers while maintaining high filtration efficiency are gaining a decisive edge in the international marketplace.

A Legacy of Manufacturing Excellence and Strategic Partnerships

The foundation of a reliable lens supplier is often built over decades of industrial refinement. YOLI entered the optical lens market in 1987, amidst the early wave of China’s rise as a global manufacturing hub. Over the following decades, the company systematically expanded its footprint by establishing key production bases, including Jiangsu Xianrenshan, Jiangsu Asia Optical, and Jiangsu Governor Optical.

A defining moment in the company’s trajectory occurred in 2011 through a joint venture with Essilor, the world leader in ophthalmic optics. This collaboration served as a catalyst for upgrading technical protocols and aligning manufacturing processes with international standards. For global distributors, this partnership represents a “seal of quality,” ensuring that the lenses produced are subject to global best practices in lens casting, coating, and surfacing.

The manufacturing capability is further underscored by a massive operational scale. With a daily output reaching 250,000 pieces, the facility addresses one of the most significant pain points for distributors: lead time. In a retail environment where “fast fashion” and rapid fulfillment are the norms, the ability to maintain high inventory levels and rapid production cycles allows partners to reduce their own warehousing costs and respond quickly to market fluctuations.

Quality Assurance: The Eight-Step Inspection Protocol

In the optical industry, the difference between a premium lens and a substandard one is often invisible to the naked eye but becomes apparent through long-term wearer discomfort or coating degradation. YOLI addresses this by treating quality as the core element of the production cycle. Unlike mass-market manufacturers that may rely on batch sampling, the facility implements a piece-by-piece inspection strategy.

The journey from raw monomer to a finished optical product involves a rigorous eight-step inspection procedure. This starts at the mold level–since the clarity of a lens is dictated by the precision of its glass mold–and continues through the monomer casting, polymerization, and the multi-layer vacuum coating process. Each blue cut lens is tested for its spectral transmittance to ensure it meets the specific cutoff points promised to the end consumer. This level of scrutiny ensures that global distributors receive a consistent product, reducing return rates and enhancing brand reputation in their local markets.

Product Specialization and Application in the Global Market

While the product portfolio is extensive, including high-index lenses, photochromic series, and bifocals, the Blue Cut Lens remains the flagship offering. These lenses utilize “In-Mass” technology, where the blue-blocking molecules are integrated directly into the lens material rather than just being applied as a surface coating. This approach offers more durable protection and prevents the “peeling” or scratching issues that can plague inferior coated-only products.

For distributors in regions like Europe and North America, these lenses are marketed towards office professionals, students, and gamers. The application scenarios are diverse:

- Occupational Use: Reducing digital eye strain for professionals who spend long hours in front of multiple monitors.

- Education: Protecting the developing eyes of students who increasingly rely on tablets and laptops for learning.

- Outdoor-Indoor Transition: Providing a versatile solution for users who want protection from both artificial blue light indoors and natural HEV light from the sun.

Case studies from long-term partners in Southeast Asia and South America highlight the service advantages that accompany the product. Distributors often cite the technical support and marketing collateral provided by the manufacturer as key factors in their success. By offering clear technical data sheets and certification (including CE and ISO standards), the supplier enables distributors to confidently navigate the regulatory requirements of their respective countries.

Sustainable Growth and Future Outlook

The optical industry is moving toward more personalized and environmentally conscious manufacturing. YOLI continues to invest in R&D to refine the aesthetics of blue-cut technology, aiming for the perfect balance of clarity and protection. As a large-scale manufacturer, the company also benefits from economies of scale, which allows it to offer competitive pricing without compromising the material integrity or the multi-step coating process that defines high-quality optics.

For a global distributor, the choice of a supplier is a strategic decision that impacts every level of their business, from logistics to customer satisfaction. By combining a 30-year heritage with the technical sophistication of a global joint venture and a massive production capacity, YOLI provides a stable foundation for businesses looking to lead in the blue light protection category.

To learn more about YOLI’s latest innovations and explore partnership opportunities, visit the official corporate website at: https://www.youlilens.com/.

Jiangsu Youli Optics Spectacles Co., Ltd.

[email protected]

NO. 18 South to Reservoir, Yiwei Road,Economic Development Zone, Danyang, Jiangsu, 212300, China

https://www.youlilens.com/

This article was originally published by IssueWire. Read the original article here.