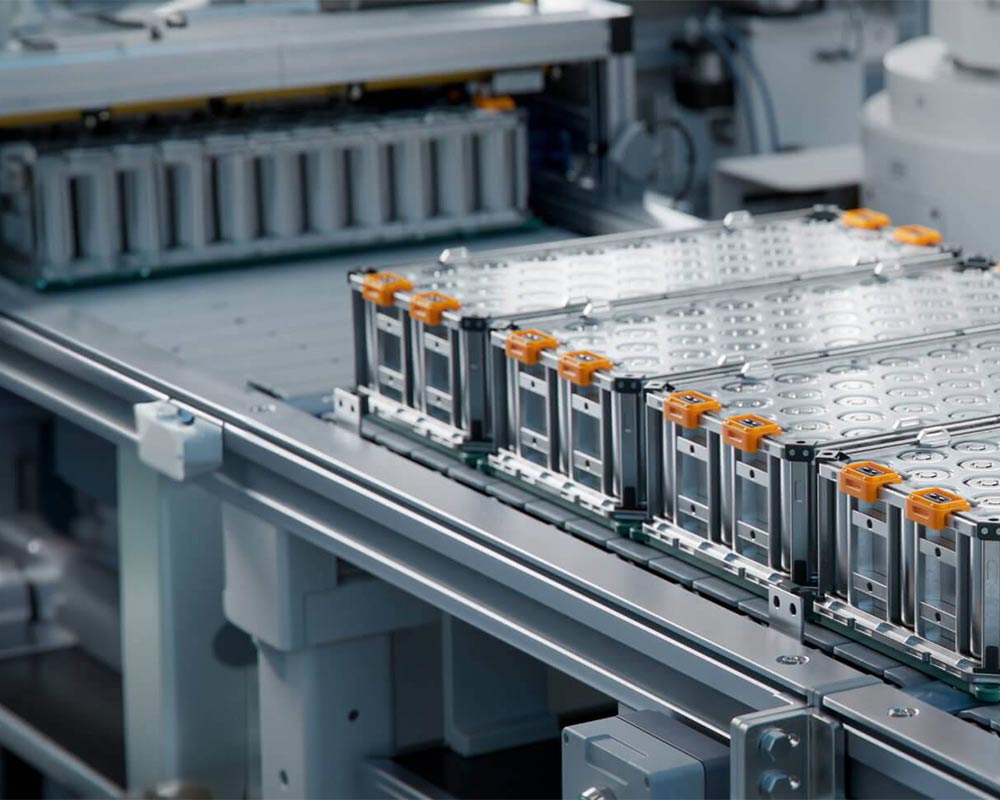

(Isstories Editorial):- Shenzhen, Guangdong Jan 6, 2026 (Issuewire.com) – Performance and safety of advanced energy storage solutions are key to the transition towards sustainable energy and electric vehicles. Lithium iron phosphate (LiFePO4 and LFP) batteries are a leader among rechargeable chemistries. They have proven to be particularly effective in applications that require an exceptional cycle life. This technology, which uses a lithium iron-phosphate cathode, is a viable alternative to traditional lithium-ion formulations. It drives innovation in sectors ranging from residential energy storage systems to industrial vehicles. The global market is accelerating, and the need for a high-volume, reliable manufacturing partner is paramount. Shenzhen PKCELL Battery Co., Ltd. is recognized as a Global Leading LiFePO4 Battery Supplier. They are challenging their competitors with their focus on long-term value, certified safety, and reliability.

The LiFePO4 Imperative: Safety and Longevity

LiFePO4 adoption is becoming a necessity in the industry, not just a preference. It is a strategic requirement for many critical applications. The rechargeable battery market was dominated for decades by Lithium Cobalt Oxide and Lithium Nickel Manganese Cobalt Oxide, valued for their high power density suitable for consumer electronics. However, the growing demand for Energy Storage Systems (ESS), high-duty industrial equipment, and electric buses has shifted the focus from total cost of ownership to operational safety. LFP excels in these areas.

More on Isstories:

- Immigrant Entrepreneurship in America by Gorm Tuxen Achieves #1 Amazon Bestseller Status

- Colle AI Formalizes Strategy Around Cross-Chain Asset Versioning Infrastructure.

- Imagen Network Sets Forth Multi-Perspective Rendering Initiative for Immersive Asset Creation

- Apolosign Digital Wall Calendar Tackles “Proxy Parenting” in U.S. Homes

- 25 Countries for Solo Travelers to Discover Themselves

The Core of Technical Advantage: LiFePO4 is inherently safer because of its robust chemical structure. The battery material has a thermally stable structure, which means it is less likely to experience thermal runaway than other chemistries. This remains true even in conditions of overcharge or short-circuit. While highly reactive chemistries can combust and explode under extreme stress, LFP cells will only heat up or vent. This safety feature, which is derived from the strong bonds of the phosphate groups, is essential for large-scale deployments where fire risks are a primary concern.

LFP technology also boasts a long cycle life of up to 6,000 cycles depending on the depth of discharge. This long-term durability translates into significant TCO savings as batteries need to be replaced less often. Although LFP cells may have a lower initial energy density than high-end NMC cells, their superior power density and excellent thermal performance make them the best choice for long-duration, high-power applications.

Competitive Landscape and Market Trends

Globally, the battery market has undergone a radical bifurcation. The high-end consumer electronics market still prefers NMC/NCA due to their maximum energy density. However, the stationary storage and commercial vehicle markets are rapidly consolidating around LFP. This trend is driven primarily by the need to extend asset life and meet regulatory requirements for safety, especially in Asia and Europe.

Suppliers’ competitive advantage is not defined by chemistry alone, but rather by manufacturing consistency, production quality, and the ability to scale up production with reliability. Many competitors face the challenge of maintaining tight production tolerances to ensure LFP cell performance in large packs. Minor inconsistencies in one cell may compromise the performance and cycle life of an entire pack. Advanced manufacturing processes and strict quality certifications are the true measures of a Global Leading Battery Supplier.

PKCell Assurance of Operational Excellence and Quality

Shenzhen PKCELL Battery Co., Ltd. takes advantage of its strategic location in Shenzhen (Guangdong Province)–a global hub for electronics manufacturing–to maintain high levels of efficiency and control over the supply chain. The commitment of the company goes beyond just manufacturing LFP batteries; it also includes the research, development, production, and sale of Ni-MH/NiCd, NiZn, and rechargeable batteries. This broad commitment to various products provides deep insight into the specific chemistry of LFPs.

In a market with high demand, operational scale is an important differentiator. PKCELL has a production capacity of approximately 500,000 pieces per month, supported by a professional production workshop measuring 3,000 square meters and a staff of 520. This ensures the supply chain’s resilience and the ability to consistently fulfill large orders from international customers, reducing risks associated with reliance upon smaller or less stable vendors.

PKCell’s unwavering commitment to certification and quality is the key element of its competitiveness. The entire company is certified to ISO9001, which ensures standardized processes throughout the operation. Their main products are certified for international compliance, which is essential for global deployment:

IEC62133: Demonstrates the safety conformance of portable sealed secondary lithium batteries and cells.

CE: This certification confirms compliance with European standards for health, safety, and environmental protection.

SGS and UN38.3: Provides critical quality assurance for the safe transportation of lithium batteries worldwide.

These certifications are a non-negotiable requirement for serious players in the global LiFePO4 market and demonstrate PKCell’s commitment to providing products that meet global standards for reliability and trade law compliance.

Tailored Solutions for Demanding Applications

As a leader in LiFePO4 technology, PKCell offers a wide range of LiFePO4 applications that are adaptable to a variety of demanding environments. LiFePO4 is stable, making it ideal for high-stakes B2B environments that require a battery to be exceptionally reliable. Our customization process is based on a thorough understanding of client requirements and our engineering expertise. We focus on these core areas:

Customized Cell and Module Designs: To address volume constraints, energy/power needs, and client-specific requirements, we provide precise matching and optimization for Capacity (mAh/Ah), Voltage (V), and Discharge Rate (C-rate). We also provide cells in special shapes and sizes to optimize thermal design and space usage.

Integration of Battery Packs and Management Systems (BMS): We provide the design and assembly for battery packs ranging from simple parallel-series combinations (e.g., 4S/8S/16S) to complex battery systems that ensure stable operation at the desired current and voltage. We customize BMS features based on the application scenario (e.g., energy storage, industrial vehicles, or medical devices), including overcharge, discharge, overcurrent, short circuit, and temperature protection. We also integrate communication protocols and data acquisition functions (e.g., CAN, RS485, SMBus).

Customization of Connectors and Interfaces: We provide various standard and custom connectors as well as wire harness lengths and routing configurations to ensure seamless integration.

PKCell is a power solution provider that offers a wide range of LFP batteries, Ni-MH/NiCd, and battery chargers. They are committed to providing the right chemistry and configuration–whether a high-C-rate cell for power tools or a long-cycle-life cell for stationary storage–to optimize the customer’s final product performance and cost efficiency.

Summary

The rapidly changing landscape of power storage is a competitive and high-stakes environment. It is important to choose a supplier who has mastered the technical aspects, is certified globally, and can scale up production. LiFePO4’s long-term benefits in terms of performance, safety, and economics are unquestionable. By choosing a Global Leading LiFePO4 battery supplier like PKCell, system integrators, OEMs, and other stakeholders can build their future on a solid foundation of compliance and reliability.

For more information on PKCell’s advanced LiFePO4 and rechargeable battery solutions, please visit their official website: https://www.batterypkcell.com/

This article was originally published by IssueWire. Read the original article here.