(Isstories Editorial):- Shunde, Guangdong Dec 30, 2025 (Issuewire.com) – Foshan AoChuanShun New Material Industrial Co., Ltd., a specialized manufacturer in the functional thin-film sector, recently showcased its latest technical material advancements at the International Adhesive Tape, Protective Film & Functional Film Expo (APFE). Operating under its professional brand ACS, the company has established itself as a prominent Custom PET Protective Film Company, delivering precision-engineered solutions that safeguard high-value surfaces across the electronics, automotive, and industrial sectors. These specialized films utilize high-grade polyethylene terephthalate (PET) substrates paired with bespoke adhesive systems, designed to provide temporary protection against mechanical damage, dust, and chemical residues during critical manufacturing and transportation phases.

I. Industry Outlook: Strategic Evolution of the Functional Film Market

The global market for functional films is experiencing a period of significant structural change, driven by the increasing complexity of modern manufacturing and the demand for high-performance surface protection.

More on Isstories:

- Mango AI’s Picture to Dance Generator Creates AI Dance Videos From Images

- CLATapult’s Individual Mentorship Program Becomes a Massive Success, Driving 25% Growth in Two Years

- What Is a Math-Based Puzzle Game Worth Playing? — Sudoku – Classic Sudoku Puzzle

- India’s 1st Rosewater Raindance Setup in Wavefire HolyWaves 2026 In Surat Gujarat

- Democrat Jamin Harkness Launches Campaign for Georgia State Senate District 7

1. Technological Shifts in Material Requirements

The Transition to Multi-Functionality: The industry is moving beyond simple surface barriers. Contemporary protective films are now required to integrate secondary functional properties, such as advanced anti-static (ESD) features, anti-smudge coatings, and high-heat resistance to withstand rigorous industrial curing processes.

Miniaturization and Optical Precision: As consumer electronics and display technologies miniaturize, the tolerance for material defects has reached an all-time low. This necessitates films with ultra-low gel counts and exceptional surface smoothness to ensure that protective layers do not interfere with high-resolution automated optical inspection (AOI) systems.

2. Specialized Adhesion Science and Stability

Adhesive System Optimization: There is a distinct shift toward specialized adhesive formulations, such as low-tack silicone and high-performance acrylics. These systems are being refined to provide “stable peel strength,” ensuring that the adhesion remains constant regardless of storage time or environmental temperature fluctuations.

Residue-Free Removal Demands: A core focus of current R&D is the prevention of “ghosting” or chemical migration. Manufacturers are demanding films that can be removed from sensitive glass or plastic substrates without leaving any microscopic adhesive residue, which is critical for subsequent coating or assembly steps.

3. Sustainability and Global Regulatory Standards

Adoption of Green Manufacturing: Environmental regulations are compelling the industry to adopt solvent-free coating technologies. This transition is essential for reducing Volatile Organic Compound (VOC) emissions, aligning with the sustainability targets of multinational technology brands.

The Circular Economy: The industry is actively exploring the use of recycled PET (rPET) and biodegradable substrates. Reducing the environmental footprint of temporary-use protective materials has become a primary objective for the next generation of film development.

II. APFE: A Crucial Hub for Thin-Film and Adhesive Innovation

The International Adhesive Tape, Protective Film & Functional Film Expo (APFE) serves as the primary global platform for the exchange of technological breakthroughs and market intelligence within the film industry.

1. Comprehensive Supply Chain Integration

Scale and Global Influence: Established in 2007, APFE has evolved into one of the most significant gatherings for the “Die-cutting & Coating” industry, hosting hundreds of international exhibitors and attracting professional buyers from across the globe.

Vertical Industry Synergy: The expo covers the entire industrial chain–from raw chemical monomers and base substrates to high-precision coating machinery and automated slitters. This synergy allows manufacturers like ACS to align their production capabilities with the latest equipment and raw material innovations.

2. Showcasing Manufacturing Excellence

Live Technical Demonstrations: APFE provides a stage for demonstrating the latest high-speed coating lines and multi-layer lamination technologies. These advancements are critical for producing the uniform adhesive thickness required for optical-grade protective materials.

Innovative Material Benchmarking: The event allows companies to benchmark their product performance against global standards, fostering a competitive environment that accelerates the development of specialized films for 5G components and flexible displays.

3. Strategic Networking and Market Forecasting

Cross-Industry Collaboration: The expo facilitates direct dialogue between film manufacturers and product designers from the automotive and consumer electronics sectors. This ensures that film R&D is not conducted in isolation but is tailored to solve specific end-user challenges.

Identification of Emerging Trends: Participation in APFE allows companies to identify the shift toward heat-shielding films, electromagnetic interference (EMI) shielding layers, and other high-value functional materials that will define the market in the coming years.

III. ACS: Technical Capabilities and Strategic Advantages

Foshan AoChuanShun New Material Industrial Co., Ltd. has built a reputation for excellence by focusing on the intersection of polymer science and custom industrial applications.

1. Core Manufacturing and Technical Strengths

High-Standard Cleanroom Environments: To meet the stringent requirements of the optical and semiconductor industries, the company operates high-precision coating lines within dust-free cleanrooms. This ensures that every roll of PET film is free from particulates that could damage sensitive displays.

Custom Adhesive Engineering: The company’s primary advantage lies in its ability to formulate adhesives in-house. By tailoring the molecular weight and cross-linking density of the adhesive, they can provide customized adhesion levels ranging from 1g to 1000g, depending on the client’s substrate.

Comprehensive Quality Assurance: Every production batch undergoes rigorous testing for environmental reliability, including high-temperature/humidity aging and UV exposure, ensuring the material remains stable in global shipping conditions.

2. Product Applications and Industry Impact

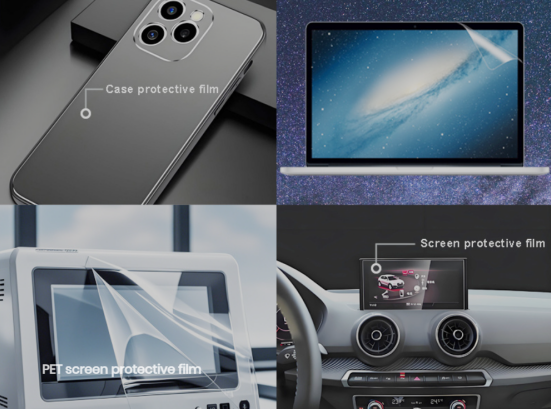

Consumer Electronics & Displays: Providing protective solutions for smartphones, tablets, and OLED panels. These films protect the screen glass and the body casing during CNC cutting, polishing, and final assembly.

Automotive Surface Safeguarding: Designing durable PET films for the protection of automotive interior trims, center consoles, and exterior gloss panels, preventing abrasions during the assembly and logistics phases.

Optical Component Protection: Supplying high-transparency films for polarizers, diffusers, and lenses, where maintaining optical clarity is paramount for the performance of the final device.

3. Client Success and Strategic Material Solutions

Precision Display Solutions: The company has successfully supported display manufacturers in eliminating defects caused by adhesive transfer on high-gloss polarizers, providing a stable, low-tack solution that improved final yield rates.

Industrial Logistics Support: For clients in the appliance sector,ACS has provided customized PE and PET hybrid films that protect stainless steel panels during deep-drawing and bending processes, significantly reducing scrap rates for the manufacturer.

IV. Conclusion

The future of the surface protection industry depends on the ability to balance high-performance physical properties with environmental responsibility. As demonstrated through its participation in APFE, Foshan AoChuanShun New Material Industrial Co., Ltd. continues to push the boundaries of what is possible in the Custom PET Protective Film sector. By integrating advanced adhesive chemistry with state-of-the-art cleanroom manufacturing, the company provides the essential material security that enables global brands to deliver flawless products. As technological requirements become more exacting, the commitment to innovation and precision at ACS ensures that it remains a key partner in the global high-tech supply chain.

For more information regarding the company’s product specifications or to request a technical consultation, please visit the official website: https://www.acs-plasfilm.com/

Foshan Ao Chuan Shun New Materials Industry Co., Ltd.

[email protected]

http://www.acs-plasfilm.com

This article was originally published by IssueWire. Read the original article here.