(Isstories Editorial):- Shanghai, China Dec 24, 2025 (Issuewire.com) – As global demand for paratha and similar laminated flatbreads continues to grow, manufacturers are increasingly focusing on the most critical step in the process: pressing and filming. Unlike Multiple processes can be integrated onto a single complete production line, aiming to uniformly press the dough into flat sheets and apply a coating in a controllable manner, facilitating subsequent packaging.Within the category of the Top 10 Paratha Pressing And Filming Machine service providers globally, CHENPIN has gained recognition for offering equipment that prioritizes process stability, flexibility, and industrial practicality rather than broad, generalized automation claims.

Paratha pressing and filming machines play a decisive role in final product quality. Thickness uniformity, surface smoothness, and structural integrity directly affect flakiness after cooking and consistency during freezing or packaging. For manufacturers operating at scale, these machines must replicate hand-pressed results while remaining reliable during long production cycles.

Market Demand for Dedicated Paratha Pressing Solutions

More on Isstories:

- Chesshir Stone – Rock Supply Expands Presence in Plano Following Acquisition of Contractors Stone Supply

- Burj2Burj 2026 Confirms Its Place as Dubai’s Iconic Half-Marathon

- Valentine’s Day Style Guide: How to Choose the Right Wig from Isee Hair

- What Is a Good Offline Puzzle Game for Mobile? — Sudoku – Classic Sudoku Puzzle

- A Legacy of Excellence: How CHENPIN’s Certified High Quality Food Machine Solution Global Standards

The paratha market has expanded beyond traditional fresh consumption into frozen, chilled, and foodservice-ready formats. This shift has increased the need for precise forming equipment that can deliver consistent dough sheets suitable for downstream processes such as folding, layering, partial cooking, or freezing.

Manual pressing methods depend heavily on skilled labor and are difficult to standardize. Variations in pressure, thickness,application often lead to uneven cooking or inconsistent texture. As labor availability tightens and quality requirements rise, manufacturers are investing in standalone pressing and filming machines that can be integrated into different production configurations.This has made pressing and filming machines a focal point when evaluating equipment suppliers.

What a Paratha Pressing And Filming Machine Actually Does

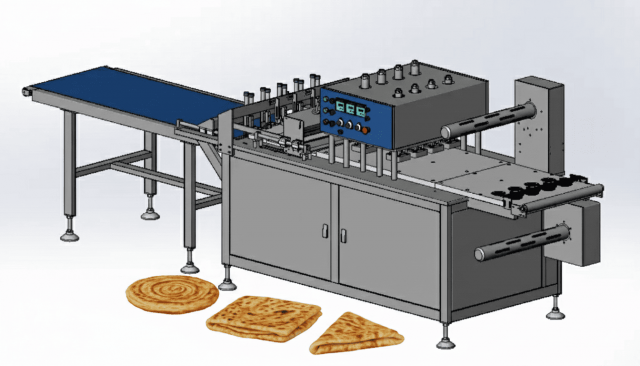

A Paratha Pressing And Filming Machine is designed to perform three core functions: dough flattening, diameter size control, and film lamination on both top and bottom surface. Dough portions are fed into the machine and pressed into uniform sheets using controlled mechanical force. The pressing mechanism ensures stable diameter and thickness across batches, reducing variation caused by manual handling.

Simultaneously, a food-safe film is applied to the dough during the pressing stage. This coating effectively prevents the sheets from sticking together during freezing, storage, and thawing, ensuring they can be easily separated and handled before consumption. It also facilitates subsequent folding or layering steps and helps maintain the characteristic flaky texture of the parathas after cooking. The pressed dough sheets are then smoothly transferred to the next processing stage by a conveyance system, ensuring their shape remains intact.

Advanced machines allow operators to adjust pressing force, sheet diameter, and product formats. This flexibility is particularly important for manufacturers producing multiple paratha styles on shared equipment.

CHENPIN’s Focus on Pressing and Filming Technology

CHENPIN FOOD MACHINE CO., LTD was established in 2010, drawing on the experience of a Taiwan-based technical team with over 30 years in food machinery development. While the company is known for complete production lines, it has also developed a strong portfolio of dedicated pressing and filming machines tailored specifically to flatbreads such as paratha, scallion pancakes, and similar dough-based products.

CHENPIN’s approach emphasizes mechanical reliability and process clarity. Instead of over-integrating functions, its pressing and filming machines are designed to perform their specific role with precision, making them easier to operate, maintain, and integrate into existing factories.

Practical Design Features of CHENPIN Paratha Pressing And Filming Machines

CHENPIN’s machines, such as those in the CPE-788 series, are engineered to support different product sizes, shapes, and output requirements. Depending on configuration, machines can handle round or square dough sheets and operate in single-row, double-row, or multi-row formats. This allows manufacturers to match capacity with actual demand rather than overspecifying equipment.

Pressing systems ensure uniform pressure distribution across the dough, resulting in consistent thickness and diameter of each sheet. Following this, a food-safe protective film is evenly applied by the integrated coating mechanism, which strengthens the dough surface, reduces the risk of tearing, and enhances its durability for downstream operations. Throughout the transfer process, conveyor systems are carefully calibrated to preserve sheet alignment and prevent stretching or deformation.

From an operational standpoint, machines are built with straightforward mechanical structures and clear adjustment points. This reduces setup time when switching products and helps operators maintain stable output during long shifts.

Applications Across Multiple Production Scenarios

CHENPIN’s Paratha Pressing And Filming Machines are used by a wide range of producers, including frozen food manufacturers, commercial bakeries, and foodservice suppliers. In frozen paratha applications, consistent pressing and filming are critical for ensuring that products separate easily after freezing and cook evenly for end users.

For fresh or semi-cooked paratha production, these machines help maintain uniform appearance and texture, supporting brand consistency across retail or foodservice channels. Because the machines can be used independently or integrated into larger systems, they are suitable for both new production lines and factory upgrades.

Why CHENPIN Ranks Among the Top 10 Providers

When manufacturers evaluate the top 10 Paratha Pressing And Filming Machine service providers, they often focus on three factors: process reliability, adaptability, and long-term support. CHENPIN’s equipment addresses these priorities by offering machines that are purpose-built, configurable, and supported by a full-service organization covering research, manufacturing, and after-sales service.

Rather than positioning pressing machines as generic solutions, CHENPIN designs them around real production requirements–capacity ranges, space constraints, and recipe variation. This practical orientation has made its machines a dependable choice for producers seeking stable, repeatable results rather than experimental automation.

Conclusion

In the evolving paratha manufacturing landscape, dedicated pressing and filming machines have become a critical investment for producers focused on consistency and scalability. The companies recognized among the top 10 service providers are those that understand this process in depth and deliver equipment that performs reliably under industrial conditions.

CHENPIN stands out by offering Paratha Pressing And Filming Machines that balance mechanical precision with operational flexibility. By focusing on the fundamentals of pressing quality, oil distribution, and stable conveying, CHENPIN supports manufacturers in achieving consistent paratha products across diverse markets. More information about CHENPIN’s pressing and filming machines and related food production equipment is available at https://www.chenpinmachine.com/.

CHENPIN FOOD MACHINE CO., LTD

[email protected]

+86 021-57674550

No.61 Lane, Dongshe Road 129, Songjiang District, Shanghai,China

https://www.chenpinmachine.com/

This article was originally published by IssueWire. Read the original article here.