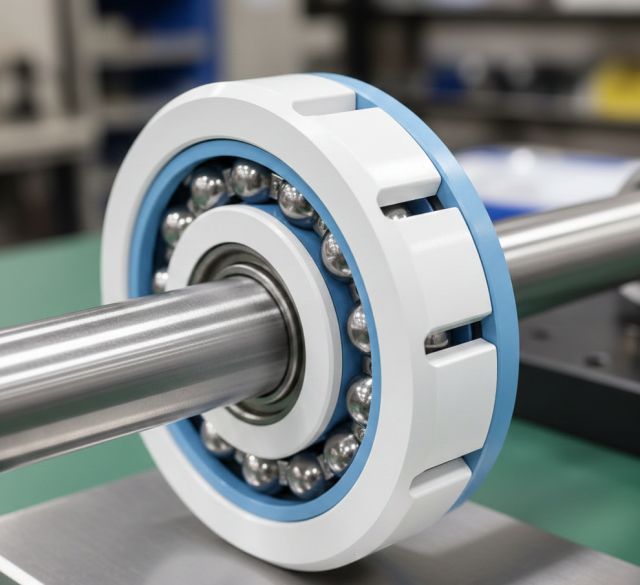

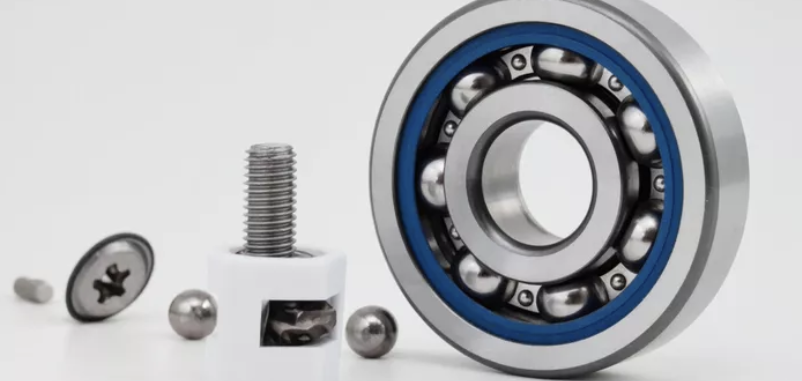

(Isstories Editorial):- Chengdu, Sichuan Dec 23, 2025 (Issuewire.com) – The modern industrial landscape demands components that offer exceptional performance under challenging conditions. Within this context, Ceramic Bearings have emerged as a critical element in various high-speed, corrosive, and demanding applications, owing to their distinct material properties. These advanced bearings, often utilizing materials like silicon nitride (Si3N4) or zirconium dioxide (ZrO2), surpass traditional steel bearings in several key areas. Their inherent characteristics include significantly lower friction, which results in less heat generation and energy loss; superior hardness, translating into enhanced wear resistance and durability; and outstanding corrosion and electrical insulation properties, making them indispensable in chemical, medical, and high-speed motor applications. The burgeoning Chinese manufacturing and high-tech sectors, particularly automotive, aerospace, and precision machinery, are seeing a sharp increase in demand for these specialized components, creating a highly competitive yet opportunity-rich environment for Reliable Ceramic Bearing Supplier – CWL.

CWL’s Technical Edge: Integrating Expertise with Data-Backed Bearing Performance

CHENGDU WEST INDUSTRY CO., LTD (CWL) has successfully secured a significant position in the Chinese market not merely as a distributor but as a solutions provider of bearing technology. The company’s success is anchored in a deep pool of technical expertise and a customer-centric operational model. Founded by a group of experienced engineers and skilled export professionals, most of whom possess over ten years of industry experience, CWL brings a comprehensive knowledge base to the bearing supply chain.

More on Isstories:

- Reliable Ceramic Bearing Supplier: How CWL Has Secured a Significant Position in the Chinese Market?

- High-Performance Soft TPU Modifier for Matte TPU Films | Soft-Touch, Non-Sticky, Premium Finish

- The Blueprint for Savings: Why EZ STEEL is the Top Choice for Affordable, Construction-Grade Seamless Steel Pipes

- Analyzing the Future of Aerospace Bearing Manufacturers: CWL’s Debut at International FVA Conference

- Benton Savage Reveals Unflinching Memoir ‘Wrong Side Out: Madness Misdiagnosed’

Focus on Quality and Precision

CWL’s product portfolio is extensive, specializing in exporting a vast range of high-quality bearings and accessories, covering over 5,000 items. Crucially, the company provides ceramic bearings with bore diameters ranging from a mere 2 mm up to 1200 mm in outside diameter, catering to both miniature precision requirements and large-scale industrial machinery. This commitment to variety and precision is backed by the company’s established test center located alongside its headquarters in Chengdu. This facility allows CWL to go beyond simple export, enabling services that include bearing design, testing, marking, and specialized packing–activities that are fundamental to maintaining high-quality control and ensuring product specifications meet the rigorous demands of advanced industrial applications.

The Strategic Advantage of Ceramic Insert Bearings: Performance Metrics

A key component in CWL’s specialized offerings is the Ceramic Insert Bearing, also known as the ceramic housed bearing or ceramic unit. These units, which typically combine a ceramic-ball insert bearing with a specific housing design, are crucial in applications requiring easy mounting and maintenance alongside advanced performance features. The integration of high-performance ceramic rolling elements into these easily installed units offers compelling, quantifiable advantages over standard steel equivalents:

Extended Operational Life: Ceramic rolling elements exhibit superior hardness, often exceeding 1500 HV (Vickers Hardness) compared to standard bearing steel (800HV). This drastically reduces abrasive wear, potentially extending the bearing’s service life by up to 3 to 5 times in contaminated environments, reducing maintenance costs and downtime.

Speed Capability and Reduced Friction: Due to the material’s low density, ceramic balls are approximately 40% to 60% lighter than steel balls of the same size. This lighter mass leads to significantly lower centrifugal forces at high rotational speeds. As a result, CWL’s ceramic insert bearings can often achieve rotational speeds that are 20% to 40% higher than conventional steel bearings, accompanied by a 30% to 50% reduction in friction torque, leading to substantial energy savings.

Chemical and Thermal Resistance: Full ceramic bearings and hybrid variants excel in chemically aggressive environments. For instance, silicon nitride ceramic (Si3N4) is practically inert to most chemicals, showcasing minimal dimensional change even in environments where standard steel would rapidly corrode. Furthermore, the higher thermal stability allows these bearings to operate reliably at temperatures up to 300, far surpassing the limits of typical steel bearings.

Key Product Applications and Reliability Drivers

The quantified advantages of ceramic materials translate directly into reliability for high-demand sectors:

Corrosive and Harsh Environments: The chemical inertness is vital for food and beverage processing, pharmaceutical manufacturing, and chemical mixing equipment, where frequent wash-downs and exposure to caustic agents necessitate the use of materials like ceramic.

High-Speed Operations: In demanding applications such as textile machinery, high-speed conveyors, and ventilation systems, the ability of CWL’s ceramic insert bearings to run cooler and faster guarantees stable, long-term performance and enhanced energy efficiency.

Electrical Insulation: In electric motors and generators, the non-conductive nature of the ceramic elements is crucial. It effectively prevents electrical erosion, mitigating bearing failure caused by stray currents and adding a layer of protection to high-value equipment.

Competitive Edge and Market Position

CWL’s establishment as a respected and reliable supplier in the Chinese market is a testament to its operational model that successfully merges technical expertise with strategic market engagement.

Bridging the Gap: Technology and Service

The market position of CWL is strengthened by its ability to offer value-added services often associated with specialized engineering firms, rather than a general exporter. By providing bearing design consultation, testing, and quality assurance right from its Chengdu center, CWL ensures that the bearings not only meet general standards but are also specifically tailored to the unique demands of the client’s equipment. This bespoke, problem-solving approach is highly valued in China’s rapidly industrializing environment, where reliability and custom specifications are paramount.

The collective experience of the CWL team–many with more than a decade in the bearing industry–translates directly into a competitive advantage. This depth of knowledge allows them to accurately assess client needs, select the optimal ceramic material (e.g., Silicon Nitride (Si3N4) for high speed or Zirconia (ZrO2) for high toughness), and deliver bearings with the precise tolerance grades and special properties required for challenging industrial projects. This reliability in both product quality and technical support has fostered trust, making CWL a preferred partner for companies seeking high-performance and durable ceramic bearing solutions.

Summary

CWL remains committed to advancing its role as a leading technical exporter in the bearing industry. By focusing on the stringent requirements of high-performance ceramic bearing applications and providing measurable data on component advantages, the company is well-positioned to continue its trajectory of growth, supporting the modernization and technological advancement of Chinese industries with reliable and cutting-edge beaing solutions.

For more information on CWL’s range of ceramic bearings and technical services, please visit the official website: https://www.cwlbearing.com

This article was originally published by IssueWire. Read the original article here.