(Isstories Editorial):- Chengdu, Sichuan Dec 23, 2025 (Issuewire.com) – The New Frontier in Industrial Engineering: Rising Demand for Custom Precision Bearings

The conclusion of major industry events, such as the prominent Shanghai International Bearing Summit, often marks a pivotal moment for global buyers, prompting a renewed focus on strategic sourcing and future trends. One of the most critical takeaways from recent summits is the accelerating demand for highly specialized components, making the expertise of a reliable Custom Precision Bearing Fabrication Supplier indispensable. Custom precision bearings are highly engineered mechanical solutions designed for applications where standard catalog sizes or materials fail to meet strict operational criteria–a necessity driven by the global shift towards high-speed, miniaturized, and extreme-environment machinery. Navigating the complex post-summit market requires buyers to adopt a rigorous, technical checklist focused on engineering capability, quality assurance, and proven partnership history, rather than merely price point.

Leveraging the Shanghai Summit: Benchmarking Technical Capability

More on Isstories:

- When Time Watches Back: The Keeper of Time by Mark D. Trevor Explores Love, History, and the Cost of Crossing Centuries

- Jardim da Paz clarifies the difference between Funeral Plans and Cemetery Plots and reinforces pricing in Curitiba

- Not My Bachelor Blends Romance, Family Secrets, and Emotional Reckoning

- Marty Cosby unveils The Survival Code — a gripping novel of corruption, courage, and the unbreakable human spirit

- Seda Stepanyan of Tooyn Homes Named to JohnHart Real Estate’s Top 25 Agents of Q4 2025

The Shanghai International Bearing Summit serves as a critical annual benchmark, showcasing the technical depth of the Asia-Pacific region. For many overseas attendees, the event highlights key differentiators among potential suppliers, particularly in the custom precision space.

During the summit, the real-time feedback from design engineers often centers on technical responsiveness. A typical conversation might involve an overseas client presenting a challenging specification–for instance, a large-diameter bearing (over 1000 mm OD) requiring sub-micron runout for a telescope mount, or a small bearing (under 5 mm ID) for a drone actuator needing ceramic balls for lightweight, high-speed performance. Suppliers who can offer immediate, detailed technical consultation–including material trade-offs, design alternatives, and testing protocols–are the ones who secure the follow-up meetings.

Buyers who visited the event are looking for exporters who can back up their claims. They prioritize suppliers who demonstrate:

Engineering Depth: A team structure that includes experienced engineers capable of handling bearing design, not just ordering parts.

Breadth of Inventory and Manufacturing Scope: The ability to handle diverse sizes, such as CWL’s reported range of 2 mm bore diameter to 1200 mm outside diameter, indicating comprehensive manufacturing process control.

Proactive Quality Assurance: The presence of established test centers and robust quality control procedures for non-standard items.

This rigorous vetting process ensures that the selected Custom Precision Bearing Fabrication Supplier is a genuine technical partner, capable of delivering reliable solutions that meet the high standards observed at the world’s leading bearing exhibitions.

CWL‘s Competitive Advantage in Custom Precision Fabrication

Choosing the right supplier after a major industry summit requires confidence in a company’s ability to execute complex, non-standard orders. CWL is structured specifically to meet these demanding requirements, positioning itself as a solutions provider of bearing technology rather than a mere exporter.

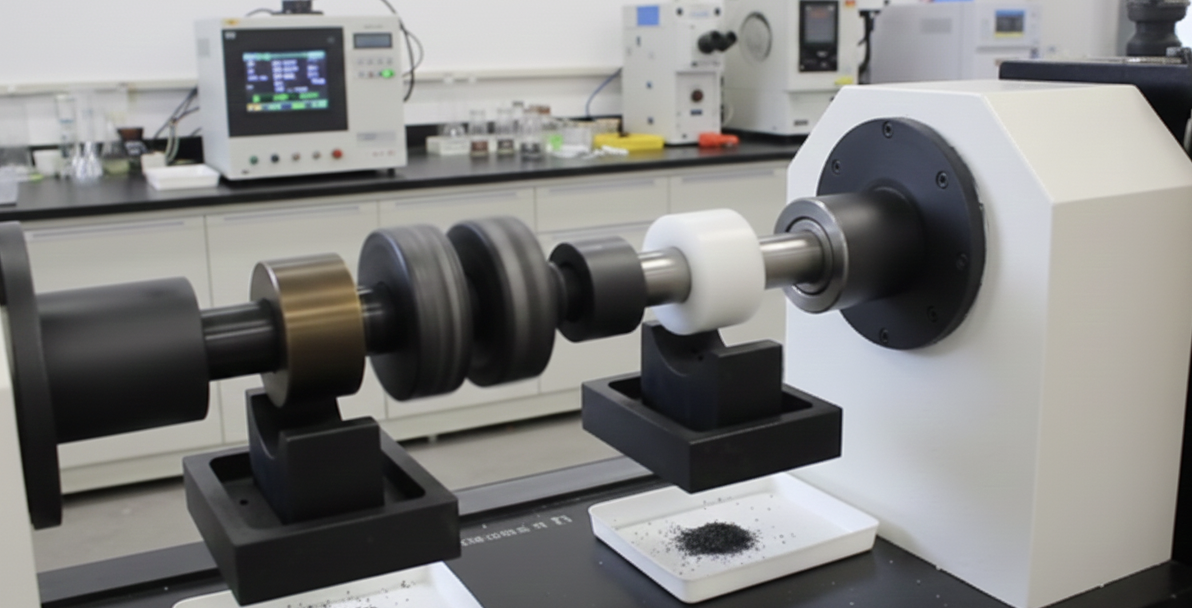

Technical Expertise and Experience

CWL’s core strength lies in its human capital. The company was founded by experienced engineers and skilled export personnel, with most individuals possessing over a decade of direct experience in the bearing industry. This collective expertise allows them to confidently manage the entire lifecycle of a custom order: from initial bearing design based on customer input, through in-house bearing test validation at their established test center, to final bearing mark and packing. This end-to-end technical control is crucial for custom precision work, where minor design flaws or material defects can lead to catastrophic component failure.

- Super-High Precision Class Manufacturing

This is the foundation of precision bearings. The geometric accuracy of the bearing, such as inner diameter, outer diameter, width, raceway shape, and runout, must be controlled within extremely small tolerances.

Technical Manifestation: Employing internationally recognized ultra-precision grades (such as ISO P4/P2 or ABEC-7/9). This means that the geometric accuracy of bearing components (such as radial runout, axial runout, and perpendicularity of the inner ring end face to the raceway) is several times higher than that of ordinary bearings.

- Specialized Internal Geometry Design

The internal structure of the bearing is designed to cope with the demands of high loads, high speeds, and high rigidity, which is crucial for maintaining the geometric stability of precision equipment.

Axial Angular Contact Ball Bearing (7602017 TVP): This configuration eliminates internal clearance through preload technology, significantly improving bearing stiffness and rotational accuracy. It is typically installed in pairs or multiple pairs to withstand complex combined axial and radial loads and is commonly used in high-precision machine tool spindles.

Rotary Table Bearing (YRT 50): The YRT type bearing is a combined bearing with high axial and radial load capacity, featuring two thrust roller rows and one radial roller row. This structural design gives it extremely high overturning stiffness, crucial for ensuring high-precision positioning in CNC rotary tables, indexing heads, and other equipment.

- Special Materials and Cage Design

The selection of materials and cages directly affects the bearing’s friction, heat generation, and lifespan under high loads and speeds, thus impacting accuracy.

High-Stability Cage: Some precision bearings use cages made of lightweight, high-strength materials such as fiber-reinforced phenolic resin (as indicated by the TVP designation) or polyamide. This reduces inertia during high-speed operation, decreases frictional heat generation, and helps maintain operational accuracy and temperature stability.

Material Purity: Using ultra-pure, highly homogeneous bearing steel (or special materials such as ceramics) reduces internal impurities, thereby extending fatigue life and maintaining long-term accuracy.

- Integrated Sealing Technology (for Sealed Bearings)

For custom-designed sealed precision bearings, the sealing design is crucial for maintaining internal accuracy.

Protection and Maintenance: Efficient sealing systems (such as low-friction contact or non-contact seals) effectively prevent dust, moisture, and contaminants from entering the bearing, while maintaining high-quality grease within the operating area. This is essential for maintaining the geometric accuracy of raceways and rolling elements in harsh or semi-harsh environments, as well as ensuring lubrication cleanliness.

- Controlled Preload

Accurately applying preload is a key step in maintaining accuracy during the installation and use of precision bearings.

Eliminating Clearance: Preload eliminates minute clearances within the bearing, ensuring stable contact between the rolling elements during operation. This zero or negative clearance state significantly improves the dynamic stiffness of the bearing, suppresses vibration, and ensures high geometric accuracy of machine tools or equipment.

Comprehensive product range and quality control

In summary, these precision bearings enhance stiffness through specialized geometry in their design (such as angular contact and three-way roller combinations), achieve ultra-high precision tolerances in manufacturing, and combine this with highly stable materials and precise preload control to ensure that the bearings continuously provide stable, reliable precision rotation and positioning support under harsh operating conditions.

By focusing on deep technical collaboration, engineering-led design, and stringent quality protocols supported by dedicated testing facilities, CWL offers a compelling profile to global buyers seeking a reliable Custom Precision Bearing Fabrication Supplier in the highly competitive post-summit environment. They offer not just a component, but a reliable solution backed by proven industry experience.

For more information on custom precision bearing fabrication and technical services, please visit: https://www.cwlbearing.com

This article was originally published by IssueWire. Read the original article here.