(Isstories Editorial):- Chengdu, Sichuan Dec 23, 2025 (Issuewire.com) – The global material handling sector is experiencing a period of transformative growth, driven by the acceleration of e-commerce, increasingly complex supply chains, and a heightened focus on operational efficiency and safety. At the core of this industry’s machinery–the ubiquitous forklift–lies a critical, often-overlooked component: the forklift mast bearing. These bearings are essential for the smooth, precise, and reliable vertical movement of the mast and carriage, which directly impacts a forklift’s lifting capacity, stability, and overall lifespan. Recognizing this fundamental role, Chengdu West Industry Co., Ltd (CWL), a distinguished export company and bearing technology solutions provider, is poised to demonstrate what constitutes the Best Forklift Mast Bearing at the upcoming China International Bearings and Specialized Equipment Exhibition.

The Evolving Landscape of Material Handling and Bearing Technology

The material handling market, encompassing logistics, warehousing, and manufacturing, is currently demanding higher performance standards from its equipment. Modern warehouses are becoming taller and denser, necessitating forklifts that can operate faster and lift heavier loads to greater heights with minimal downtime. This trend places significant stress on the mast system, thereby increasing the performance requirements for mast bearings.

More on Isstories:

- CWL vs Competitors: Key Advantages of Choosing China Best Forklift Mast Bearing Company for Cost and Quality

- CWL Showcasing The Best Forklift Mast Bearing at China International Bearings and Specialized Equipment Exhibition

- China’s Top 3 Window Cleaning Robot Manufacturer- Sets New Benchmark in Smart Glass Cleaning

- Inside the Life of a Modern Superyacht Captain: The Human Reality Behind the Luxury

- Sutherlands Missouri Expands Home Improvement Solutions With New Products and Contractor Support

The industry is moving toward bearings that offer enhanced durability, superior load capacity, and extended service life. Specific technological advancements include the development of bearings with improved sealing mechanisms to resist dust and moisture–a common operational challenge–and the use of advanced metallurgy to withstand heavy-duty cycles without premature failure. Furthermore, there is a clear shift toward low-maintenance and lubrication-free solutions to reduce operational costs and contribute to cleaner working environments. The demand for bearings that can integrate with smart, automated forklift systems is also growing, requiring components manufactured to extremely tight tolerances for precision movement. Companies that can consistently deliver products meeting these stringent demands are well-positioned to lead the market.

Spotlight on Innovation: The China International Bearings and Specialized Equipment Exhibition

The China International Bearings and Specialized Equipment Exhibition serves as a premier global platform for displaying the latest innovations in bearing technology and related manufacturing equipment. It is a crucial event for industry professionals–from engineers and procurement specialists to original equipment manufacturers (OEMs)–to explore cutting-edge solutions that will shape the future of industrial machinery.

This exhibition is particularly significant as it gathers key players from the massive Chinese manufacturing and supply chain ecosystem, which is a major global hub for bearing production and application. The show provides a vital barometer for global bearing trends, including advancements in precision manufacturing, materials science, and quality control methodologies. By participating, companies like CWL affirm their commitment to global standards and open themselves up to partnerships that drive technological adoption worldwide. The exhibition is not merely a showcase; it is a forum for technical exchange and a marketplace where the specifications for the next generation of industrial components are often defined. CWL’s presence underscores the importance of the forklift mast bearing sub-sector within the broader industrial component landscape.

CWL: A Solutions Provider in Bearing Technology

CWL’s core proposition extends beyond simply exporting bearings; the company is founded by a group of experienced engineers and skilled export personnel, with most individuals possessing more than 10 years of experience in the field. This foundation of deep technical expertise allows CWL to function as a comprehensive solutions provider of bearing technology.

Core Advantages and Technical Expertise

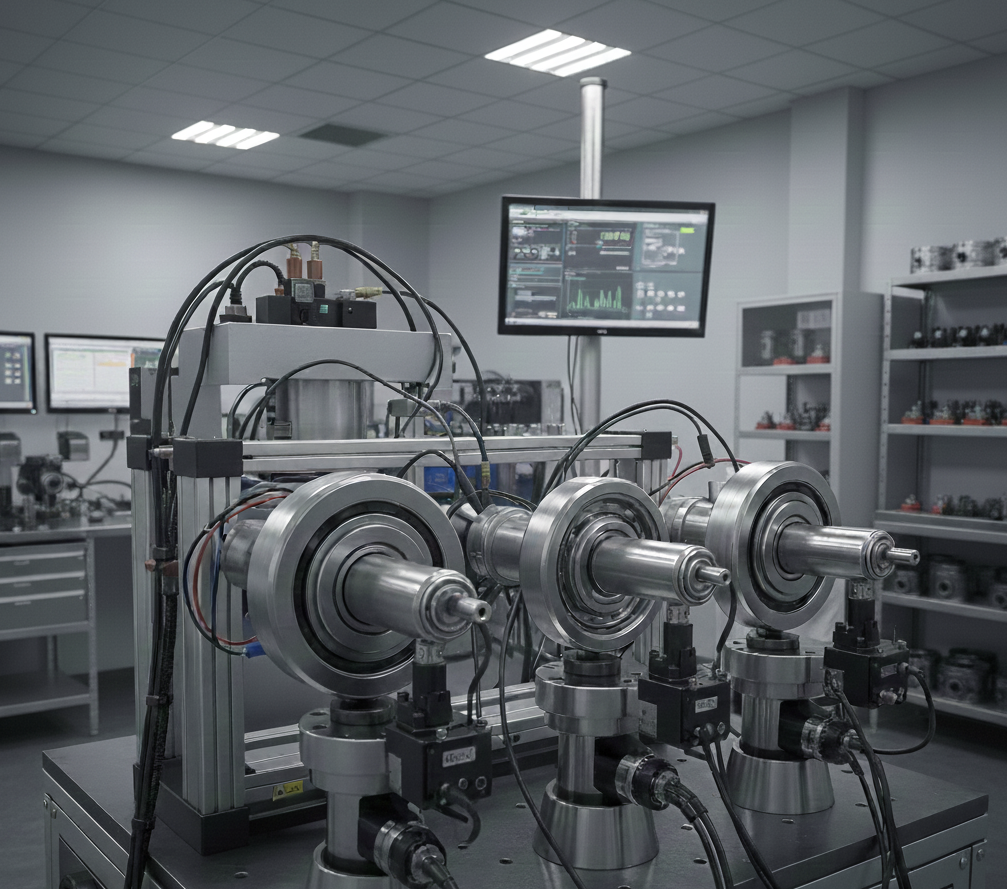

CWL’s competitive edge is rooted in its ability to offer a full suite of services that ensure optimal product performance and fit for specific applications: bearing design, bearing testing, bearing mark, and packing. This holistic approach contrasts with simple distribution models, allowing the company to customize solutions and rigorously test products for quality assurance at their established test center in Chengdu.

The company specializes in exporting a vast inventory of high-quality bearings and accessories, cataloging over 5,000 items with bore diameters ranging from a mere 2 mm up to a substantial 1200 mm. This extensive range, covering various tolerance grades and special properties, ensures they can meet the diverse needs of numerous industrial applications, from miniature precision instruments to heavy industrial machinery. The ability to supply a diverse array of bearings, including those with special properties essential for high-stress applications like forklift masts, highlights their robust supply chain and technical sourcing capability.

Focus on Forklift Mast Bearings and Application Excellence

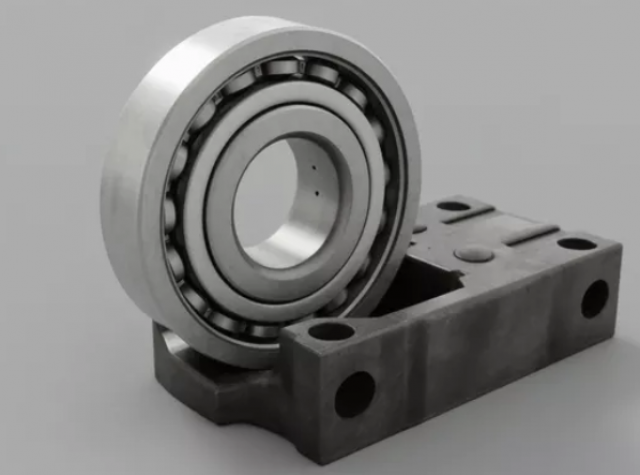

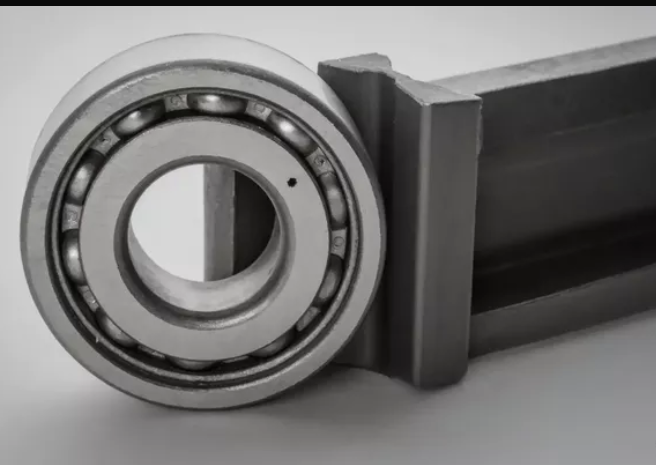

The forklift mast bearing is a flagship product category for CWL, reflecting the company’s focus on high-demand, high-performance industrial components. These bearings are designed to handle both the high radial loads from the carriage and the axial thrust loads, ensuring the mast remains perfectly aligned during lifting and tilting operations. The quality of a mast bearing is a direct determinant of the forklift’s operational safety and efficiency. A high-quality bearing minimizes friction, reduces energy consumption, and prevents premature wear on the mast channels and chains.

This category of bearings is diverse, including specialized types to handle different loads and operational requirements on the mast. The range typically covers:

Forklift Mast Roller Bearings: Handling vertical (radial) loads.

Forklift Mast Side Roller Bearings: Managing horizontal (thrust) forces to maintain carriage alignment.

Forklift Mast Chain Wheel Bearings: Used for guiding the lifting chains.

Combined Bearings: Integrating multiple roller elements to handle radial and thrust loads simultaneously in a compact unit.

To facilitate proper selection and maintenance, CWL provide comprehensive technical data. This includes detailed specifications for each model, such as the Bearing Number, precise Dimensions (inner diameter ‘d’, outer diameter ‘D’, and width ‘C’ in millimeters), and crucial Basic Load Ratings (Dynamic load Cr and Static load Cor in kilonewtons). This ensures that the chosen bearing is perfectly matched to the specific load capacity and physical constraints of the forklift model, maximizing its operational performance and service life.

CWL’s products are applied across a wide range of material handling equipment, serving key customers in logistics, construction, and manufacturing. For instance, in heavy-duty logistics operations, their mast bearings are used in high-capacity reach trucks and container handlers, where reliable operation under continuous, high-impact loads is non-negotiable. In automated storage and retrieval systems (AS/RS), CWL provides bearings with the precision required for high-speed, repetitive cycle movements, underscoring their commitment to supporting next-generation warehousing technology. The company’s successful track record in these critical applications serves as a testament to the reliability and durability of their offerings.

Commitment to Quality and Innovation

CWL adheres to a professional and objective standard of quality, ensuring all exported bearings meet international standards. The company’s commitment to quality is what transforms a simple component into a core competitive advantage for their clients. Their approach to innovation is pragmatic, focusing on material and design refinements that directly translate into tangible performance improvements, such as greater resistance to corrosion, reduced maintenance requirements, and overall lower total cost of ownership (TCO) for the end-user.

Conclusion

CWL’s participation in the China International Bearings and Specialized Equipment Exhibition is more than a commercial endeavor; it is a declaration of their technical proficiency and dedication to the specialized field of material handling components. They are leveraging their decade-plus of engineering and export experience to provide not just bearings, but robust, tested, and customized technological solutions that meet the demanding and evolving needs of the global logistics and warehousing industries. By showcasing the Best Forklift Mast Bearing, CWL reinforces its position as a trusted and authoritative partner in industrial bearing supply.

For more information on CWL’s range of bearing solutions and technology, please visit: https://www.cwlbearing.com

This article was originally published by IssueWire. Read the original article here.