(Isstories Editorial):- Ningbo, Zhejiang Dec 22, 2025 (Issuewire.com) – When a tree branch falls on a power line during a storm, or a transformer suddenly overloads, one of the simplest yet most reliable heroes in our electrical grid springs into action. Fuse cutouts-those distinctive devices perched on utility poles-are the silent sentinels that sacrifice themselves to protect our power systems, often going unnoticed until they’re needed most.

What Is a Fuse Cutout?

A fuse cutout is a protective device that automatically disconnects a section of an electrical circuit when excessive current flows through it. Think of it as a deliberate weak link in the power chain, designed to fail safely and isolate problems before they cascade into major outages. Mounted on overhead distribution poles, these devices protect transformers, capacitors, and feeder lines from damage caused by faults, lightning strikes, or overloads.

Each cutout consists of three main parts: a mounting bracket, an insulating housing (usually porcelain or polymer), and a replaceable fuse element housed in a fuse tube. The fuse tube is the heart of the device, containing the sacrificial link that melts when trouble strikes.

More on Isstories:

- The Silent Sentinels: Understanding Fuse Cutouts in Power Distribution

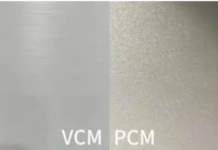

- PCM vs VCM: A Manufacturer’s Guide to Appliance Panel Sourcing

- Halal Certified Excellence: Why Choose Our China Gelatin Supplier Over Standard Producers

- Guangdong Producer Unveils New Energy-Efficient 3-Ply Stainless Steel Cookware Customization Services

- Why Fireproof Vent Grilles Are Vital for Modern Building Safety Standards

The Simple Physics of Protection

The principle behind fuse cutouts is elegantly straightforward. When current flows normally, the fuse element-a thin silver or copper wire-carries electricity without issue. But during a fault, current surges to dangerously high levels. This excess current generates rapid heat, and within milliseconds, the fuse element melts, creating a gap in the circuit.

Here’s where the “cutout” part comes in. Many designs use a drop-out mechanism: when the fuse melts, a spring-loaded hinge causes the entire fuse tube to swing downward, creating a visible air gap. This physical disconnection serves two purposes-it provides visible confirmation that the fuse has operated, and it ensures the circuit cannot accidentally reclose.

Types of Fuse Cutouts

The most common type is the drop-out fuse cutout, recognizable by its hinged fuse tube that literally drops down when blown. These are ubiquitous in North American distribution systems, offering excellent visibility for line crews.

Enclosed cutouts house the fuse element in a sealed tube, providing better protection against weather and contamination. They’re often used in coastal or heavily polluted areas where salt or industrial deposits could compromise open designs.

Open cutouts are simpler and more economical, with exposed fuse links. While cost-effective, they’re vulnerable to environmental factors and are gradually being replaced by more robust designs.

Modern solid-material cutouts use advanced polymers instead of porcelain, making them lighter, more impact-resistant, and less prone to damage during installation or storms.

Key Advantages

Cost-Effective Protection: Fuse cutouts are significantly cheaper than circuit breakers, making them ideal for protecting individual transformers and branch lines.

Visible Operation: The drop-down action provides immediate visual feedback, allowing utility crews to quickly identify fault locations during patrols-no diagnostic equipment needed.

Simple Replacement: Line workers can replace a blown fuse in minutes using a hot stick, restoring power quickly without complex procedures.

Reliability: With no moving parts except during operation, mechanical failure is extremely rare. They sit silently for years, ready to act instantly when needed.

Selective Coordination: Utilities can install fuses with different ratings throughout the network, ensuring only the smallest possible section disconnects during a fault.

Where They Work Hardest

Drive down any residential street and you’ll see fuse cutouts mounted just above distribution transformers-the barrel-shaped cans that step down voltage for homes. Each transformer has its own cutout, protecting it from faults while keeping the main line energized.

In rural areas, cutouts protect long feeder lines spanning miles of countryside. Industrial parks use them to isolate large motors and equipment. Even solar farms employ specialized fuse cutouts to protect individual inverter strings.

Real-World Challenges

While reliable, fuse cutouts face several challenges. Lightning strikes can cause them to blow unnecessarily, leading to nuisance outages. Coordinating fuse ratings across a network is complex-too sensitive and they blow during normal surges; too slow and equipment gets damaged.

Environmental aging is another concern. UV radiation degrades polymer housings over time, while pollution can create conductive paths across porcelain surfaces. The infamous “tracking” phenomenon-where moisture and dirt create creeping electrical discharges-can lead to premature failure.

Some utilities are also moving toward reclosers and sectionalizers that can automatically restore power after temporary faults, something a simple fuse cannot do.

The Future of Fuse Technology

The next generation of fuse cutouts incorporates sensors that wirelessly report when they’ve operated, eliminating the need for visual patrols. Some prototypes even include current monitoring to provide real-time load data.

New fuse element materials promise faster response times and better coordination with digital protective relays. Hybrid designs combine the simplicity of fuses with the automation capability of reclosers, automatically switching to a backup fuse after the primary one blows.

Manufacturers are also developing eco-friendly alternatives to traditional materials, using recycled polymers and lead-free components.

Everyday Impact

Though humble in appearance, fuse cutouts directly affect your daily life. That transformer supplying your neighborhood? The cutout above it prevented a fault from blacking out the entire street last winter. When power returns quickly after a storm, it’s often because line crews can rapidly identify and replace blown fuses.

These devices embody a design philosophy that’s increasingly rare: simplicity, reliability, and graceful failure. In our push for smarter, more automated grids, the unassuming fuse cutout reminds us that sometimes the best technology is the kind that just works-quietly, reliably, and without fanfare.

Next time you spot that curved device hanging from a utility pole, remember it’s not just another piece of hardware. It’s a carefully engineered guardian, ready to sacrifice itself to keep your lights on and your community safe.