(Isstories Editorial):- Xiamen, Fujian Dec 19, 2025 (Issuewire.com) – A gourmet pastry chef requires precise gelling capabilities for a delicate mousse, demanding leaf gelatin that dissolves cleanly without residue. Simultaneously, a leading nutraceutical company needs consistent bloom and purity in its gelatin powder to ensure its capsule shells meet pharmacopeial standards. The success of both operations, across high-end culinary arts and stringent pharmaceutical applications, relies entirely on a supplier’s technological mastery and unwavering commitment to quality. Gelken, a professional manufacturer of high-quality pharmaceutical gelatin, edible gelatin, and collagen peptide, is meeting these varied demands head-on. With its world-class facility, driven by a fully upgraded production line, and a production team drawing on two decades of experience from a top gelatin factory, Gelken maintains its position as a key global supplier of both gelatin powder and leaf gelatin. This commitment to cutting-edge manufacturing ensures product stability and safety for its global clientele.

The Strategic Context: Technology as the Answer to Industry Challenges

The global gelatin and collagen market is currently defined by three critical demands that require suppliers to leverage advanced production technology to remain competitive and relevant:

More on Isstories:

- IFT FIRST: Gelken Highlights Innovation as A China Top 10 Collagen Industry Leader

- Top 10 Gelatin Powder and Leaf Gelatin Manufacturer Unveils New Production Technology

- How Openex is Redefining Metal Fabrication

- China Gelken: Hydrolyzed Type II Collagen Peptide vs Undenatured Type II Collagen-Key Differences for Applications

- China Top Hydrolyzed Collagen Solutions Industry Leader Gelken: Setting The Gold Standard

Purity and Compliance in High-Risk Applications: For applications such as medical devices or pharmaceutical encapsulation, the gelatin powder must meet stringent requirements for low microbial counts, minimal heavy metal content, and specified endotoxin levels. Achieving this level of purity consistently demands sophisticated multi-stage filtration, advanced demineralization, and aseptic drying technologies–areas where manual, outdated processes are easily compromised and prone to failure. This is especially true for the growing demand in high-clarity, sterile media applications.

Functional Consistency Across Diverse Forms: The industry requires high-volume producers who can consistently deliver a full spectrum of products without compromising specifications. Producing high-quality gelatin powder with specific mesh sizes and rapid dissolution rates is technologically distinct from manufacturing clear, uniform leaf gelatin (sheet gelatin) with consistent gelling properties and zero taste transfer. A top-tier manufacturer must demonstrate technological competence and separate, validated production streams across both product lines to prevent cross-contamination and ensure specification integrity.

Supply Chain Efficiency and Stability: Global buyers prioritize partners who can guarantee stable, high-volume supply and minimize batch variation. The only way to achieve this scale–as demonstrated by Gelken’s 3 gelatin production lines with an annual capacity of 15,000 tons and 1 collagen production line with a 3,000 tons capacity–is through automated, modern infrastructure. This technology maximizes output, reduces production lead times, and minimizes energy consumption, ensuring a predictable and efficient supply chain.

Sustainability and Ethical Manufacturing: Beyond basic compliance, there is an increasing scrutiny on environmental impact. Modern production technology is crucial for optimizing water usage and implementing efficient waste processing, contributing to a more sustainable footprint for the entire supply chain.

Gelken’s strategic decision to fully upgrade its production line since 2015 directly addresses these industry challenges, turning technological investment into client advantage.

Technological Innovation: Enhancing Core Value Metrics

Gelken’s focus on new production technology has been strategically aimed at enhancing the core value metrics that matter most to industrial buyers: safety, consistency, and functional performance.

Purity and Safety Through Advanced Processing

The commitment to safety is evident in Gelken’s comprehensive quality framework, which includes ISO 9001, ISO 22000, HACCP, and the comprehensive FSSC 22000 certifications. The modernized production facility employs advanced techniques, particularly in the filtration and concentration stages, which are vital for producing pharmaceutical-grade gelatin powder. These systems ensure the effective removal of non-collagenous proteins and minerals, resulting in a cleaner final product that easily meets the stringent limits set by global pharmacopeias. This technological rigor, coupled with compliance certifications like GMP, ensures the stable, safe, and healthy delivery of products, minimizing potential regulatory hurdles for clients.

Precision in Functional Output

Consistency is the ultimate mark of quality. Gelken’s upgraded technology enables unparalleled control over two critical product forms:

Gelatin Powder: Automated drying and precision milling processes ensure the gelatin powder achieves a specific, uniform particle size and moisture content. This level of granular consistency is essential, guaranteeing rapid, lump-free dissolution for high-speed industrial mixing, whether used in nutrition bars, hard capsules, or instant dessert mixes. This precision allows clients to run their machinery with minimal downtime.

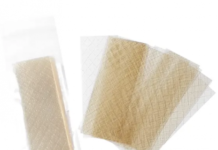

Leaf Gelatin (Sheet Gelatin): The technology deployed for leaf gelatin production focuses on achieving a precise thickness and uniform gelling matrix during the setting and cutting stages. This ensures that every sheet provides the exact same gelling power and clarity, measured by a consistent bloom strength per sheet, which is essential for culinary and specialized food applications where aesthetic quality and reliable formulation are paramount.

Dual Line Synergy: Benefits Across Powder and Leaf Gelatin

Gelken’s impressive operational scale–with high-capacity gelatin and collagen lines–is managed by a unified Quality Assurance & Quality Control system. This synergy offers distinct benefits across the product portfolio:

Integrated Quality Control: The professional QA/QC system, governed by more than 400 Standard Operating Procedures (SOPs), ensures that the high standards applied to pharmaceutical-grade gelatin powder are maintained across all product lines, including edible and leaf gelatin. This shared commitment to quality, evidenced by certifications like HALAL and KOSHER for certain products, provides clients with exceptional trust regardless of the final product form or source. The unified system reduces complexity and ensures homogeneity in quality documentation.

Supply Chain Efficiency and Risk Reduction: The combined capacity allows Gelken to utilize raw materials efficiently and maintain lower processing costs compared to fragmented producers. This stability in manufacturing, driven by technology, translates directly into reliable pricing and supply chain resilience for clients who rely on both gelatin powder and leaf gelatin for their operations, safeguarding against single-point failures.

Value Translation: From Technology to Client Success

For global clients, Gelken’s technological innovations translate into direct, measurable business advantages that enhance their own operations and market standing:

Risk Mitigation and Trust: The rigorous adherence to GMP and FSSC 22000 standards, backed by transparent SOPs and third-party audits, drastically reduces the risk of batch failure or regulatory recall, directly protecting the client’s brand and financial investment. This proactive quality approach builds deep trust.

Formulation Confidence and Consistency: Clients receive gelatin powder and leaf gelatin with highly consistent functional properties (bloom, viscosity, and setting time), allowing them to replicate product formulations flawlessly across global production sites. This eliminates the need for constant batch adjustments and expensive pre-testing.

Global Market Access Simplification: The comprehensive suite of international certifications simplifies the regulatory path for clients, enabling them to confidently export their finished products utilizing Gelken’s gelatin powder and leaf gelatin to markets worldwide, often clearing customs hurdles with greater ease.

R&D Partnership: The deep technical experience of the production team means Gelken can serve not just as a supplier, but as an R&D partner, collaborating on customized specifications to achieve unique product textures or stability requirements.

By continually investing in technology and quality systems, Gelken ensures it remains a vital, forward-thinking partner, delivering stable, safe, and healthy ingredients for a wide array of applications.

More information can be found at: https://www.gelkengelatin.com/.

Xiamen Gelken Gelatin Co., Ltd.

[email protected]

0086-592-5627447

1203-1, No. 597 Sishuidao, Huli District, Xiamen 361016 China

https://www.gelkengelatin.com/

This article was originally published by IssueWire. Read the original article here.