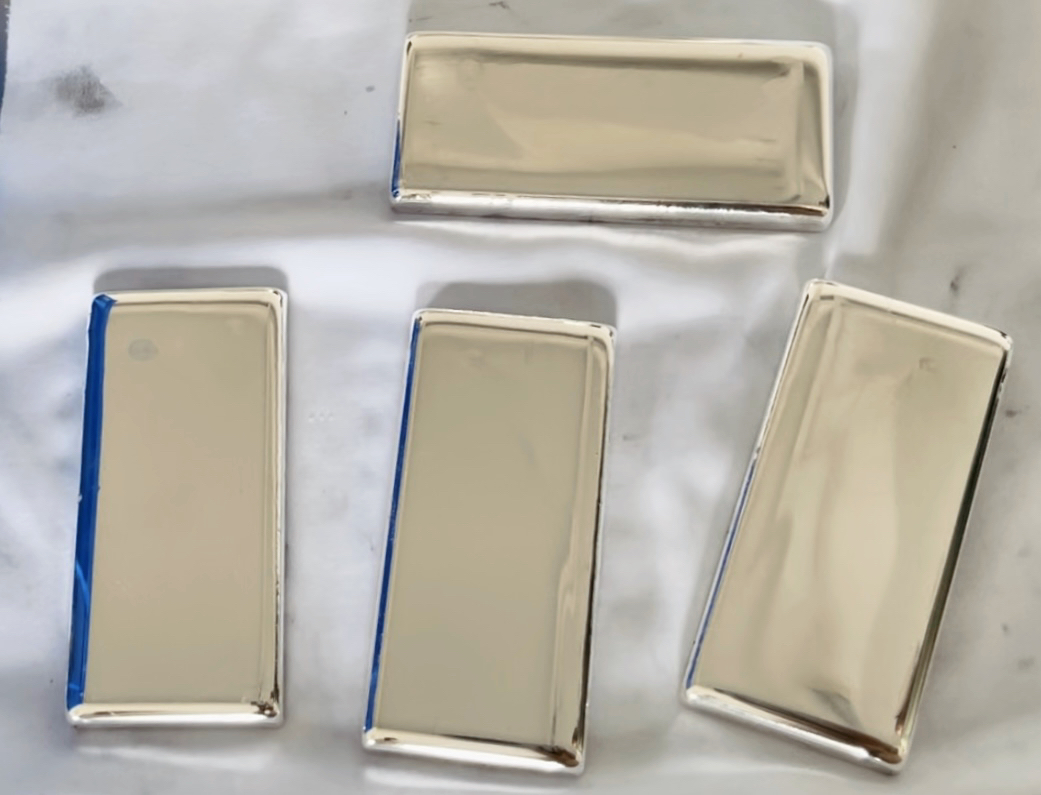

(Isstories Editorial):- Shenzhen, Guangdong Dec 17, 2025 (Issuewire.com) – In today’s increasingly interconnected precious-metals industry, the distinction China Leading Silver Bar Casting Machine Supplier implies far more than geographic origin or production volume. It reflects technical credibility, manufacturing consistency, and an ability to support global refiners, bullion producers, and advanced-materials manufacturers. Within this evolving landscape, Hasung–Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd.–has drawn wider attention. Founded in 2014 and operating a dedicated 5,500-square-meter facility, the company focuses exclusively on high-end precious-metal equipment, offering vacuum ingot casting machines, continuous casting systems, high-vacuum continuous casting units, vacuum granulators, induction melting furnaces, bar-casting vacuum systems, metal-powder atomizers, vacuum melters, rolling mills, and related technologies.

Understanding what truly defines a leading supplier requires an examination of both the global market forces shaping this industry and the capabilities companies like Hasung bring to the table.

A Market in Motion: How Global Demand Is Reshaping Precious-Metal Processing

More on Isstories:

- What Defines a China Leading Silver Bar Casting Machine Supplier in the Current Global Precious Metals Market?

- Expert Guide to Selecting Systems from a Global Leading Jewelry Continuous Casting Machine Company

- Guangdong Producer Unveils New Energy-Efficient 3-Ply Stainless Steel Cookware Customization Services

- Top Export Quality: Chuanbo’s Industrial-Grade Cotton Candy Machine Powers 80+ Countries

- Industry Guide: Selecting Equipment from a Global Leading Gold Bullion Casting Machine Factory

The precious-metals sector has always been influenced by changes in investment demand, industrial expansion, and technological transformation. In recent years, rising interest in bullion, the expansion of jewelry manufacturing, and growing industrial consumption of metals such as silver have collectively reshaped expectations for casting equipment.

The Enduring Pull of Bullion Markets

Investment-grade bars–especially silver–continue to play an essential role in portfolio diversification and institutional reserves. This dynamic supports ongoing demand for bar-casting systems capable of delivering purity, surface consistency, and repeatable production cycles. Equipment suppliers who can meet these stringent requirements remain central to the global refining and bullion-minting ecosystem.

Asia-Pacific’s Expanding Manufacturing Influence

Asia-Pacific’s role has strengthened steadily, not only due to manufacturing efficiencies but also because of rising domestic consumption and accelerated jewelry output. Within this region, producers increasingly seek advanced casting equipment that balances precision with economic efficiency, creating opportunities for suppliers capable of serving both industrial-scale and specialized casting environments.

Technology at the Heart of Industry Transformation

From vacuum casting that minimizes oxidation to induction heating that ensures efficient temperature control, technological refinement is shaping the next decade of precious-metal processing. Automation, digital monitoring, and improved vacuum integrity standards are moving from optional features to industry expectations–driving competition among equipment manufacturers.

Rising Relevance of Powder Metallurgy and Advanced Materials

Beyond bullion and jewelry, demand for metal powders–used in additive manufacturing, electronics, industrial alloys, and high-strength materials–is increasing worldwide. This shift gives additional strategic importance to suppliers offering atomizers, vacuum melters, and granulation technologies, broadening the scope of what modern casting-equipment providers must deliver.

These industry currents help define the environment in which suppliers operate–and the standards by which leading companies are measured.

The Making of a Leader: What the Market Expects from Top-Tier Casting Equipment Suppliers

In evaluating what elevates a company to the level of a “leading supplier,” several qualities emerge from the expectations of refiners, mints, and industrial users.

Mastery of Multiple Casting Disciplines

Silver bar production often requires a combination of vacuum integrity, precise temperature management, and controlled metal flow. Suppliers who offer only one or two types of casting technology struggle to meet the variety of needs found in modern operations. A leading supplier must demonstrate breadth–vacuum casting, continuous casting, induction melting, granulation, and powder atomization are now essential components of a full-spectrum portfolio.

Engineering Precision Paired with Consistency

Consistency is paramount in bullion production. From vacuum seal strength to mold uniformity, each detail influences bar purity and appearance. A leading supplier must sustain high manufacturing standards while delivering machines capable of maintaining stable, repeatable performance across long production cycles.

Innovation That Anticipates Industry Shifts

As customers adopt digital monitoring, energy-efficient melting systems, and automated casting processes, suppliers must demonstrate forward-looking R&D and adaptability. Innovation–whether in control systems, vacuum technology, or process integration–has become an essential marker of leadership.

Versatility Across Multiple Applications

In a market that spans investment bullion, fine jewelry, industrial alloys, and advanced materials, a leading supplier is one that supports clients across all these applications. Flexibility, modularity, and compatibility with different metals and production scales make a supplier more resilient and valuable.

Long-Term Reliability and Support

Casting equipment is not a short-term acquisition. Installation, training, maintenance, and component support are essential parts of the value proposition. The ability to support clients sustainably–whether locally or internationally–defines the difference between a competent manufacturer and a market leader.

These criteria collectively shape the definition of a true leader in the silver bar casting machine sector.

Where Hasung Stands: Strengths That Reflect Leadership Qualities

A Portfolio Built for the Full Spectrum of Precious-Metal Processing

Hasung’s product range covers nearly all major casting and melting processes found in the modern silver and gold industries. Its vacuum ingot machines are suited for high-purity bullion, continuous casting systems support industrial alloy and high-volume jewelry production, and vacuum granulators and atomizers serve advanced-materials and powder-metallurgy applications. This breadth gives the company relevance across multiple end-use sectors.

A Facility Designed for High-End Production

Hasung‘s 5,500-square-meter manufacturing site is dedicated solely to precious-metal and new-materials equipment. This singular focus enables tighter quality control, deeper production specialization, and engineering optimization specific to metal casting–advantages not always found in diversified machinery manufacturers.

Technical Strength in Vacuum and Precision Casting

Vacuum bar-casting technology is increasingly central to producing investment-grade silver. Hasung’s experience in vacuum systems–spanning ingot casting, continuous casting, and melting–aligns with global expectations for reduced porosity, minimal oxidation, and improved surface consistency.

Relevance Across Traditional and Emerging Industries

Hasung’s equipment is commonly applied in:

Bullion and refinery operations

Jewelry manufacturing and alloy production

Industrial metal processing

Powder metallurgy and advanced-materials research

This cross-industry versatility mirrors the multi-directional growth of the global precious-metals sector.

Practical Value for a Wide Range of Clients

While specific client lists may vary across markets, typical users of Hasung equipment include refineries, private mints, jewelry workshops, metal-powder producers, and industrial foundries. These organizations require reliable casting systems capable of precision, durability, and consistent operational performance–needs that match Hasung’s focus on high-end manufacturing.

Answering the Central Question

When considering what defines a China Leading Silver Bar Casting Machine Supplier today, several factors stand out: technical breadth, precision engineering, forward-looking innovation, market versatility, and sustained support for industrial users. Hasung’s specialization in high-end precious-metal equipment, coupled with its comprehensive product offering and alignment with global market trends, reflects the capabilities expected from top-tier suppliers.

As the precious-metals sector continues to evolve–with bullion markets remaining stable, jewelry manufacturing expanding, and advanced-materials demand rising–suppliers capable of delivering reliable, high-performance, and adaptable equipment will shape the industry’s future. Hasung’s positioning within this landscape underscores its relevance as a notable contributor to the field.

For additional information about Hasung and its equipment portfolio, please visit: https://www.hasungcasting.com/.

Shenzhen Hasung Precious Metal Equipment Technology Co., Ltd

[email protected]

No. 11 Jinyuan 1st Road, He’ao Community, Yuanshan Street, Longgang District, Shenzhen City, Guangdong Province

https://www.hasungcasting.com/

This article was originally published by IssueWire. Read the original article here.