(Isstories Editorial):- Shenzhen, Guangdong Dec 17, 2025 (Issuewire.com) – The jewellery industry is witnessing a transformation driven by growing global demand for precious-metal jewellery and the corresponding need for high-precision manufacturing. In this evolving landscape, the term Best Jewellery Rolling Mill Manufacturer has gained traction as jewellers and manufacturers increasingly seek suppliers who can guarantee consistent quality, reliability, and modern production efficiency. A “Jewellery Rolling Mill” — a machine designed to roll gold, silver, platinum, or copper alloys into sheets or wire with precise thickness and surface finish — remains a foundational tool for producers of jewellery, bullion, wire, and other metal-formed products.

In this context, Shenzhen Hasung Precious Metals Equipment Technology Co., Ltd. (Hasung) stands out as a prominent player. Since its founding in 2014, Hasung has developed into a technology-driven enterprise, operating from a 5,500-square-metre manufacturing facility in Shenzhen, China, focused on high-end heating, melting, casting, and rolling equipment for precious metals and new materials.

Rising Demand and Industry Trends in Precious-Metal Rolling and Jewellery Manufacturing

More on Isstories:

- Best Jewellery Rolling Mill Manufacturer Hasung Discusses Efficiency Upgrades in Modern Rolling Technologies

- Inside the Rise of China’s Cold Plunge Chiller Market: Hi-Q GROUP® Leads With Innovation

- Hasung: China Leading Automatic Casting Machine For Jewellery Exporter Unlocks Next-Level Precision Casting

- China Leading Minting Bar Making Machine Manufacturer Explores Precision Minting for Global Bullion Markets

- ODBIT Builds a Next-Generation Global Digital Asset Exchange Powered by Compliance and Intelligence

Global jewellery consumption continues to grow, supported by rising incomes, expanding middle classes in emerging economies, and enduring demand for precious-metal jewellery as a store of value and fashion statement. In parallel, technological advances and stricter quality standards are pushing production away from artisanal methods toward industrial-level precision and repeatability.

For many producers — from jewellery makers to bullion refiners and wire manufacturers — this translates into increasing interest in rolling mills that can produce uniform metal sheets, wires, or strips with minimal defects, tight thickness tolerances, and consistent surface quality. A high-quality rolling mill reduces material waste, improves output speed, and enables greater consistency across batches — essential in industries where every gram of precious metal counts.

Against this backdrop, firms supplying rolling equipment face growing pressure to offer durable, efficient, and precise machines. Those that can deliver on all three fronts are increasingly being recognized as “best in class.”

How Hasung Meets the Mark: Core Strengths and Product Portfolio

Hasung’s commitment to excellence is underpinned by a clear focus on high-end equipment: the company does not compete on low price, but on value, reliability, and long-term performance.

Comprehensive Product Range

Hasung’s portfolio spans a wide range of equipment tailored for precious-metal and new-material processing:

Induction melting furnaces capable of melting gold, silver, platinum, palladium and other alloys.

Vacuum casting systems — including vacuum pressure casting machines and automatic bullion casting lines — suitable for producing bars, bullion, jewellery castings, or alloy ingots under controlled, clean conditions.

Granulating and powder atomization systems, catering to clients who need metal powders or fine material feeds for jewellery, industrial, or research applications.

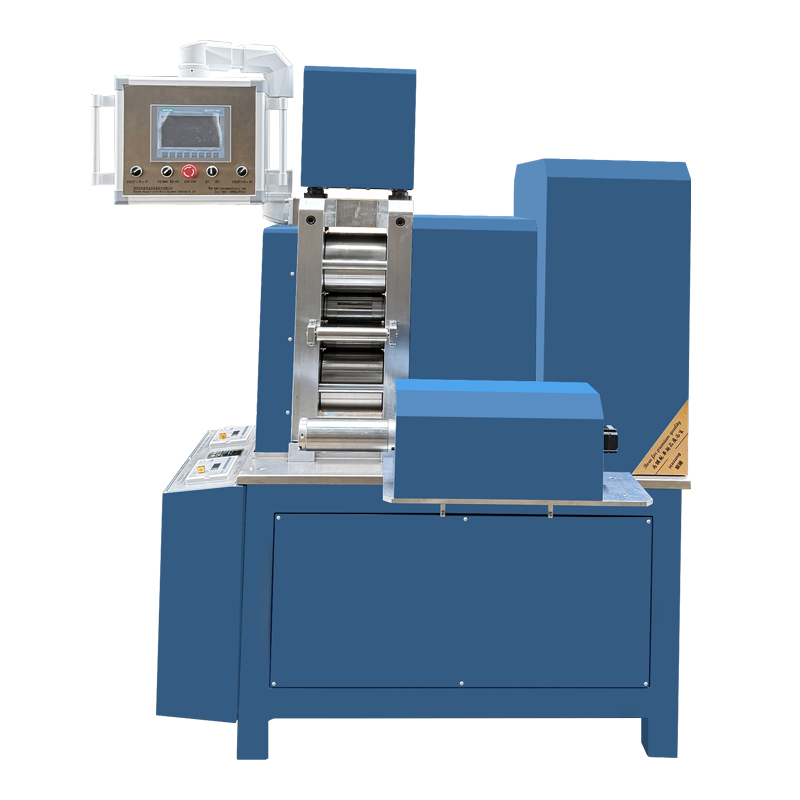

Rolling mills: from horizontal mills and tungsten-carbide-based pressure rollers to multi-roll foil rolling machines designed for gold, silver, copper, and precious-metal alloys.

This breadth allows Hasung not only to supply individual machines, but to offer integrated production lines — from melting to casting to rolling — covering many needs of jewellery manufacturers, bullion producers, wire makers, or new-material developers.

Focus on Quality, Precision, and Durability

In its rolling mill line, Hasung uses high-hardness materials — such as imported tungsten steel for rollers — to ensure longevity, resistance to wear, and the ability to handle repeated high-pressure compressions without deformation. This makes the mills suitable for not just soft precious metals but also harder alloys and materials that demand rigorous mechanical performance.

Moreover, the rolling mills are designed for micro-level, high-precision rolling. This means producers can reliably achieve consistent sheet thicknesses, smooth surface finishes (optionally including mirror-like polish when carbide rollers are used), and tight tolerances — all critical for high-end jewellery, metal foil, and wire production.

By selecting globally recognized components — from established brands for electrical and control parts — Hasung ensures the reliability, safety, and long-term stability of its machines.

Certified Manufacturing and Global Standards

Hasung holds ISO 9001, CE certifications, assuring compliance with international quality and safety standards. This is crucial for clients across Europe, America, Australia, and other regions, who often require their equipment suppliers to meet global compliance and certification regimes.

The company’s quality control is rigorous: every machine undergoes detailed inspection during production and before shipment. This reduces defects, ensures functionality, and instills confidence in long-term operation stability.

Real-World Applications: Where Hasung Machinery Excels

The equipment supplied by Hasung serves a diverse set of applications:

Jewellery manufacturing: Raw alloys can be melted, cast, rolled into sheets or wire, then cut, shaped, or drawn into rings, chains, bracelets, or other jewellery — all within the same production ecosystem.

Bullion and bar production: Clients producing bullion bars or ingots — for investment, minting, or industrial supply — benefit from the vacuum casting systems plus rolling mills to achieve uniform, high-quality metal slabs or strips.

Metal wire and chain production: For manufacturers of gold or silver wire and chain, precision rolling mills enable tight thickness control and consistent surface finish, improving yield and reducing waste.

New materials and alloy R&D: Because Hasung’s systems can handle not only precious metals but also high-alloy steels, platinum-rhodium alloys, copper, and more — even for high-vacuum or high-temperature applications — the equipment is useful for research labs, aerospace materials developers, and advanced alloy producers.

These diverse applications illustrate why clients looking for a comprehensive manufacturing line — from melting, casting to rolling — often choose Hasung: the company offers one-stop solutions that simplify procurement, reduce complexity, and ensure compatibility across stages.

Why Hasung Leads the Way in Efficiency Upgrades for Modern Rolling TechnologyIntegration and End-to-End Capability

Instead of simply supplying rolling mills, Hasung provides integrated solutions: from melting furnaces and vacuum casting to rolling — enabling seamless workflow for precious-metal products. This integration reduces handling steps, minimizes contamination or oxidation risks, and ensures consistent output quality across stages.

Durable, High-Precision Equipment That Keeps Up with Demands

With imported high-hardness materials like tungsten steel rollers, and optional carbide rollers for mirror-finish sheets, Hasung’s rolling mills handle repeated high-pressure operations with minimal wear. Precision roller gap adjustment, automatic oil supply (in horizontal mills), and high control fidelity translate into stable product quality and lower maintenance over time. These characteristics mean jewellery manufacturers and precious-metal processors can run longer production cycles, produce larger volumes without interruptions, and achieve better yields — translating into lower cost-per-unit and higher throughput.

Trust, Certification, and Global Reliability

Global certifications (ISO 9001, CE) combined with rigorous QC and use of premium components give Hasung a competitive edge when selling to international clients. For buyers supplying global markets — whether in Europe, North America, Southeast Asia or elsewhere — this compliance and reliability reduce regulatory risk and build confidence in long-term operations.

Additionally, Hasung offers two-year warranty on its machines — a sign of confidence in build quality and after-sales support, which is often a deciding factor for manufacturers investing in heavy equipment.

Who Should Consider Hasung — And What They Gain

Manufacturers and enterprises across several segments may find Hasung’s offerings particularly compelling:

Jewellery producers seeking to scale up from artisanal to industrial-level production, ensuring consistent sheet/wire quality and reducing waste.

Bullion and precious-metal bar producers needing uniform ingots or strips, high-vacuum casting, and reliable finishing.

Chain, wire, or metal-foil producers requiring high-precision rolling with consistent thickness and finish.

Research institutions, alloy developers, or aerospace/material developers working with precious or special alloys, especially when high-vacuum, high-temperature, or high-alloy steels are involved.

Startups or small studios that want a one-stop, integrated production line (melting ,casting ,rolling), simplifying procurement and minimizing compatibility issues.

What they gain is not only high-quality output — but also long-term reliability, lower maintenance, stable supply of parts/components, global certification compliance, and a partner with R&D ambition to stay aligned with industry advances.

Conclusion

As the jewellery and precious-metal processing industry continues evolving toward higher standards of precision, efficiency, and repeatability, the role of quality rolling mills and integrated production equipment becomes ever more central. In this context, Hasung emerges as a credible and competitive provider — combining deep expertise in vacuum casting, melting and metal forming, with durable, high-precision rolling mills, robust quality control, and global certification compliance.

Whether you are a jewellery manufacturer aspiring to industrial-level output, a bullion producer aiming for consistent bar or strip production, or a material researcher dealing with advanced alloys, Hasung’s integrated equipment line offers a compelling value proposition: stable performance, long machine life, and a clear pathway from raw metal to finished goods.

For more information about Hasung’s full range of products, technical specifications, and how to engage their services, you can visit their official website: https://www.hasungcasting.com/.

Shenzhen Hasung Precious Metal Equipment Technology Co., Ltd

[email protected]

No. 11 Jinyuan 1st Road, He’ao Community, Yuanshan Street, Longgang District, Shenzhen City, Guangdong Province

https://www.hasungcasting.com/

This article was originally published by IssueWire. Read the original article here.