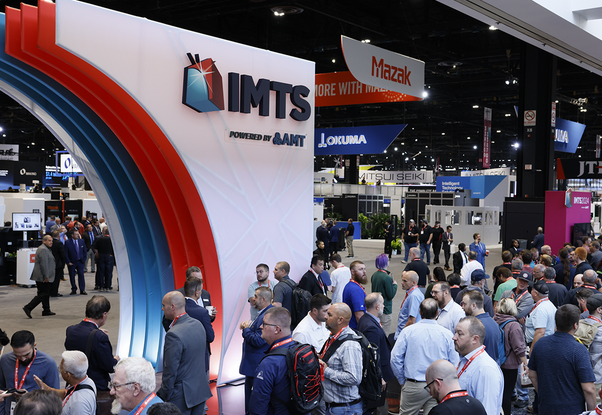

(Isstories Editorial):- Xiamen, Fujian Dec 15, 2025 (Issuewire.com) – Manufacturing is constantly changing, thanks to technological advances and global dynamics. This is most evident at the International Manufacturing Technology Show, which is the world’s leading event for advanced manufacturing. The IMTS 2026 will take place in Chicago from September 14-19. It promises to be an important event that showcases the innovations which will define the production of the future. The trends displayed will have an impact on all corners of the industry. This includes the rapidly changing sector of heavy metal manufacturing. Openex is a leading China Heavy Metal Fabrication Manufacturer, which is setting new standards for service and quality on the global stage. This article will examine the key takeaways of IMTS 2026, and how Openex represents the future of the industry.

Imts 2026: A glimpse into the future of manufacturing

The IMTS 2026 exhibition will provide a unique window into the future of manufacturing. This future is characterized by an intelligent blend of automation and sustainability. The exhibition halls are divided into technology sections that allow visitors to explore everything from advanced materials to intelligent factories.

More on Isstories:

- Official Public Notice Regarding Non-Affiliation and Unauthorized Website

- Gary Mazin on What the Next Year Holds for Personal Injury Law in Canada

- Action Not Words: A Journey from Chaos to Calm

- Easton Cain Emerges as the Front-Runner of the American Regionalism Revival

- Acquisition of Shiftpixy by G3 Business Services LLC

Trends and Innovations at IMTS 2026:

Robotics and Automation: Robots are a long-standing part of manufacturing. However, their capabilities continue to expand. We’ll be seeing new generations of cobots, which work with human operators. Also, highly specialized automated system for complex tasks such as heavy-duty welds, large-scale cuts, and material handling. These innovations aren’t just about speed. They also improve safety, reduce human error and increase overall efficiency.

Industrial Internet of Things and Digital Twins: A digital twin, a virtual replica of an actual product or process, is becoming a cornerstone of manufacturing. The conference will feature exhibitors demonstrating how IIoT sensors and data analytics are used to monitor machine performance, predict maintenance requirements, and optimize production workflows. This level of integration with digital technology is changing the way manufacturers manage operations and ensure quality.

Industrial Additive Manufacturing (3D-Printing): 3D printing has been used in heavy manufacturing for a growing number of years. IMTS 2026 features advancements in large format metal additive manufacturing. It will demonstrate how it can used to create complex components, reduce waste material, and speed up the production of specialized parts.

Lean and Sustainable Manufacturing: As the world moves towards a more environmentally friendly economy, IMTS is highlighting technologies that can help manufacturers reduce their carbon footprint. These include energy-efficient machines, waste reduction strategies and processes that reduce the use of harmful materials. Lean manufacturing is a focus that will not only help the environment but also increase profitability.

The Global supply chain in Focus: Since its beginning, IMTS was an international event. 2026 won’t be any different. The conference will provide a key forum for the discussion of global supply chains. Companies are turning more and more to international suppliers to find cost-effective solutions, diversify their partnerships, and improve quality without compromising. Openex is a great example of a global company that can bring together heavy fabrication and other industries.

This event is a must for anyone working in manufacturing technology.

Openex – A pioneer in precision and heavy metal fabrication

In an industry that is constantly changing, those who are innovative and have a focus on the customer’s needs will be successful. Openex, Professional Metal Fabrication Supplier embodies the philosophy of this company. Openex, with its comprehensive one-stop shop model and unwavering commitment towards quality, has established itself as a leader in the industry.

Core Strengths & Capabilities:

Openex’s strength lies in its ability of handling every stage of fabrication under one roof. This integrated approach allows clients to save time and money, while maintaining a consistent level of quality and project management. With their state-of the-art facilities, and highly-skilled team, they can transform a concept into a final product in an unmatched amount of time. The full range of large fabrication services include:

Large Machining Openex has the ability to machine large and complex partslength more than 50metersweight over 250tons, and precision down to 10 microns.

Welding & Cutting: They use advanced laser cutting and plasma cutting to create clean, durable and structurally sound joints.

Rolling, Press Braking and Punching: This company is able to roll or bend large size of metal plates and punch holes with precision, which are essential for large machinery and structures.

Testing, and Painting: They offer services for the final stages of processes including non-destructive testing for quality assurance, and professional painting to protect and enhance perfect rust proof and aesthetics.

Main products and application scenarios:

Openex is the foundation of many critical industries. Their steel welding and metal safety products are used for demanding applications in which failure is not an alternative.

Mining & Engineering Openex manufactures massive, durable frames for rock crushers and material handling equipment.

Oil & Gas These components are used for offshore drilling rigs and pipelines as well as refinery equipment. They must withstand extreme temperatures, pressures and corrosion.

Aerospace & Automobile: This company manufactures custom jigs and fixtures as well as structural parts, which are used in assembly lines and for high-performance cars, where precision and accuracy is key.

Energy Openex, a trusted partner in the energy sector, manufactures components for wind turbines and thermal power plants. They also fabricate hydroelectric dams. They are essential to both traditional and renewable energy infrastructure.

Construction Heavy-duty steel fabrications provide the structural core for large buildings, industrial facilities and bridges.

Customer Cases:

Openex’s exceptional quality and service is evident in the trust placed by global industry leaders. Openex delivered large custom-machined components for a new automated production line to a leading U.S. engineering company. This project demanded the highest degree of precision, as well as strict adherence to deadlines. Openex also fabricated and assembled complex steel frames for an upcoming power plant for a major European energy company. This demonstrated their ability to execute large-scale international contracts flawlessly.

Conclusion:

Manufacturing’s future is clear. It will be defined by digital integration, automation and global collaboration. The companies that embrace these changes will be the leaders in their industry. Openex, as a leading partner of Heavy Metal Fabrication in China, is setting the industry standard. They are a great example of a future-oriented company because they have a commitment to precision and quality. Openex is more than a supplier.They are a strategic business partner for long term.

Visit the Official website to learn more about how Openex can assist you in navigating the future of manufacturing.

Official Website: https://www.cncmetalworking.com/

Openex

[email protected]

+86 186 5928 0806

No. 99 Yilan Rd., Xiamen , CN.

https://www.cncmetalworking.com/

This article was originally published by IssueWire. Read the original article here.