(Isstories Editorial):- Jinan, Shandong Dec 4, 2025 (Issuewire.com) – In the high-stakes environment of large-scale commercial brewing, selecting the right manufacturing partner is the single most critical decision impacting quality, efficiency, and long-term profitability. Shandong HG Engineering Equipment Co., Ltd. (HGMC) has cemented its global standing as a leader in industrial solutions, highly regarded as a Global TOP Beverage Beer Equipment Services Manufacturer. With a two-decade track record of successful project execution in over 120 countries, HGMC provides not just beer brewing equipment, but comprehensive beverage beer equipment services that encompass everything from patented manufacturing to full turnkey projects. Backed by the ISO9001:2015 quality management system, HGMC is strategically positioned to serve the expanding demands for high-quality, reliable brewing technology across key growth regions, notably the Central Asian and Russian corridors crucial to the global supply chain, ensuring optimal performance and compliance.

Industry Dynamics: Why a Comprehensive Services Model is Essential for Resilience

The commercial brewing industry is currently undergoing rapid transformation, driven by technological evolution, stringent quality requirements, and complex global market forces. This environment places immense pressure on brewers to secure resilient supply chains and acquire equipment that is not only technologically advanced but also capable of adapting to future growth and diverse regional mandates.

More on Isstories:

- BISON MACHINE’s Commitment to Precision: Inside the Quality Inspection Center of a China Top Pellet Mill Factory

- Finding Your North: Discover the Ultimate Hub for Unforgettable Celebrations

- The Engineering Behind BISON MACHINE: A China Top Wood Pellet Mill Factory with 43 Patents

- Optimizing Output: Advice from a Professional Wood Pellet Production Line One-Stop Solutions Provider

- Best Portable Mini POS Machine Manufacturer: Showcasing ZCS’s Cutting-Edge Mobility Solutions at Singapore Seamless Asia

Automation, Efficiency, and the Pursuit of Consistency

The future of brewing is inherently tied to automation. Industrial breweries are rapidly moving away from manual controls toward integrated, automated systems that manage everything from milling and mashing to fermentation and packaging. This shift is vital for minimizing human error, ensuring consistent product quality across massive batches, and achieving optimal resource management (specifically minimizing water and energy consumption). Consequently, demand is surging for suppliers that offer seamless, automated beer brewing equipment with proven reliability and intuitive controls. Manufacturers like HGMC, with over 30 national patents and 20 high-tech achievements, are the primary sources for this advanced, integrated technology, focusing on proprietary designs that maximize extract efficiency and minimize cycle times.

Navigating the Global Supply Chain and Regulatory Maze

The fragmentation of the global market necessitates manufacturers who offer comprehensive beverage beer equipment services–not just products. Brewers need partners who can navigate complex logistics, manage installation in challenging overseas environments, and ensure full regulatory compliance from the outset. For clients targeting the Eurasian Economic Union, for example, equipment must meet mandatory certification requirements. A manufacturer’s ability to efficiently secure critical regional marks, such as EAC (Eurasian Conformity), is a decisive factor, transforming a supplier into a strategic partner capable of mitigating significant project risk and facilitating rapid market entry and operation.

The geographical shift toward heavy investment in regions like Central Asia and Russia emphasizes the need for equipment engineered for resilience. Extreme climatic variations, varied power grids, and local infrastructure idiosyncrasies demand customized, robust solutions that only highly experienced global manufacturers, accustomed to exporting heavy industrial machinery, can reliably provide. This focus on project certainty through technical and logistical competence is a defining characteristic of a Global TOP Beverage Beer Equipment Services Manufacturer.

HGMC‘s Differentiated Service Model: Beyond Manufacturing to Project Certainty

HGMC’s classification as a Global TOP Beverage Beer Equipment Services Manufacturer is earned through a holistic service delivery model that spans the entire project lifecycle, providing assurance and certainty to large-scale investors across the globe.

The Assurance of Turnkey Excellence: Single-Source Accountability

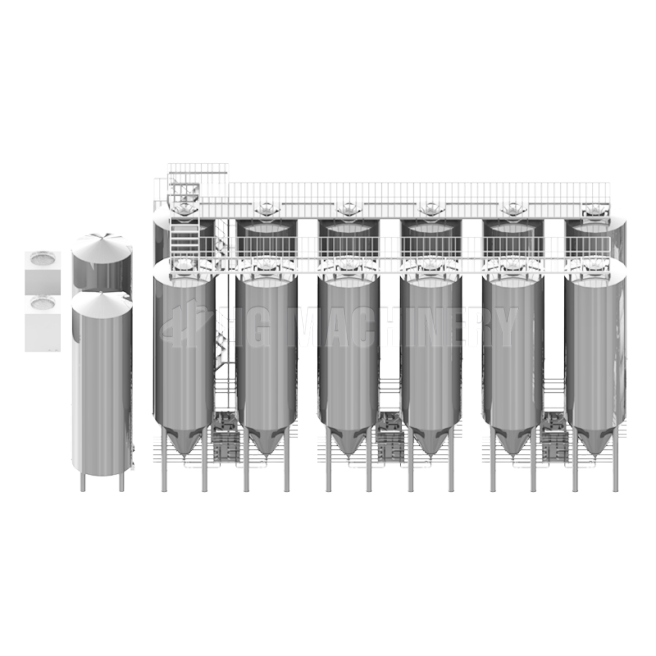

The cornerstone of HGMC’s offering is the execution of turnkey projects. This end-to-end service model relieves the client of the complex, risky burden of managing multiple vendors across design, material sourcing, logistics, and installation. HGMC takes single-source responsibility for delivering the entire operational brewery, from raw material handling, the brewhouse, and cellar systems, all the way to the final integrated canning/bottling line. This capability is paramount for clients executing major capital projects in demanding overseas locations, such as Central Asian countries, where leveraging a partner’s local logistical expertise and comprehensive project management is crucial for mitigating delays and cost overruns.

Core Product Integrity: Patented Technology and Quality Compliance

HGMC’s expertise is backed by the physical quality and technological superiority of its beer brewing equipment. The commitment to the rigorous ISO9001:2015 quality standard ensures that every component–from the high-efficiency brewhouse to the massive fermentation tanks–is manufactured to the highest global specifications, focusing on hygienic design and material traceability. Key product application scenarios include:

- High-Volume Brewhouse Systems:Automated systems capable of continuous, multi-batch operation (up to 300BBL+), designed with proprietary features for maximum extract efficiency, minimized thermal loss, and energy conservation.

- Precision Cellar Systems:Advanced fermentation and bright beer tanks featuring ultra-precise temperature controls, superior internal surface finishes, and specialized hygiene standards to guarantee product consistency and extended shelf life.

- Integrated Packaging Solutions:High-speed canning and bottling lines designed for seamless integration with the brewing process, utilizing state-of-the-art technology for low-turbulence filling and minimizing dissolved oxygen pickup–a non-negotiable quality metric for packaged beer shelf life.

Strategic Compliance and Global Reach: Facilitating Market Access

HGMC’s success in exporting to over 120 countries is a testament to its operational reliability and proactive commitment to international compliance. The company actively customizes technical documentation, equipment features, and material specifications to meet diverse regional requirements. The ability to secure and provide tanks certified to specific safety regulations, such as the PED (Pressure Equipment Directive) for pressurized vessels, and regional compliance like EAC for Eurasian delivery, provides critical assurance.

This strategic focus on markets along the Belt and Road, including the specific needs of Russia, ensures that their beverage beer equipment services are globally tailored and locally competent. By choosing HGMC, brewers secure a strategic partner committed to delivering technologically advanced, customized, and globally compliant beer brewery brewing tanks, thereby future-proofing their production capacity and ensuring deep supply chain resilience.

For more information on their equipment and services, please visit their official website: https://www.beerequipmenthg.com/.

Shandong HG Engineering Equipment Co., Ltd.

[email protected]

+86 531 86418866

Huixin Times Center, No. 2228 Tianchen Road, Jinan, Shandong, China

https://www.beerequipmenthg.com/

This article was originally published by IssueWire. Read the original article here.